Sourcing prayer books can feel overwhelming. You need them to be durable, beautiful, and reflect the sanctity of their purpose, but standard options often fall short. A poorly made prayer book with flimsy pages or a weak binding can detract from the user’s experience and reflect poorly on your institution. Understanding the key production choices is the first step to creating a lasting impression.

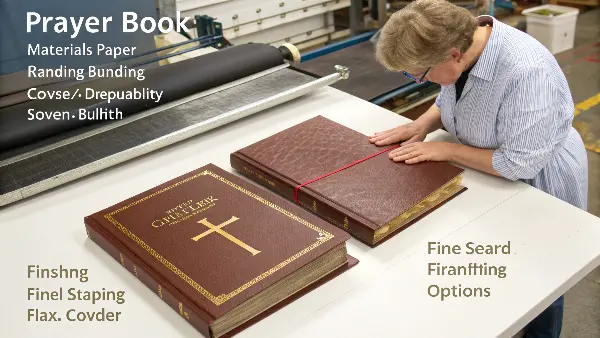

High-quality prayer book production involves carefully selecting durable, elegant paper for the interior and a distinguished material like leather or fine cloth for the cover. Binding methods such as Smyth-sewn are chosen for longevity and their ability to lay flat. Finally, special finishing options like foil stamping, debossing, and gilding are applied to enhance the book’s sacred and aesthetic appeal, creating a truly treasured item.

As a manufacturer, I’ve seen firsthand how these details transform a simple book into a cherished spiritual tool. Getting them right is not just about aesthetics; it’s about creating an object that can support a person’s faith journey for years to come. The right combination of materials and craftsmanship ensures the final product is worthy of its important contents. Let’s break down the most critical choices you’ll need to make.

Which Paper and Cover Materials Are Best for Prayer Books?

You want the feel of a prayer book to match its spiritual importance. But choosing the wrong materials can be a real problem. Cheap paper tears easily, and a plain cover can lack the sense of reverence you’re aiming for. This makes the book feel disposable, not cherished. Let’s look at materials that convey permanence and respect, ensuring the final product feels right in every way.

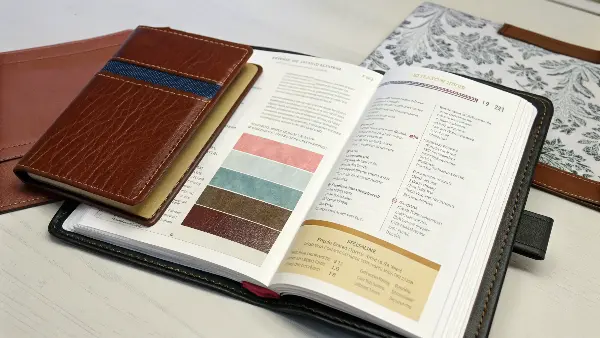

For prayer book interiors, the best papers are thin yet opaque, like bible paper or lightweight offset stock (50-70 gsm), to keep the book light while preventing ink bleed-through. For covers, durable and elegant materials are key. Genuine leather, faux leather (PU), and high-quality book cloths offer a premium feel and longevity, ensuring the book can withstand daily use and become a treasured keepsake for generations.

When I work with clients like Michael, a product development manager from Germany, the conversation always starts with the materials. The feel of the book is the first thing a user notices. For the inside, we need to balance delicacy with durability.

Interior Paper Choices

The goal for interior pages is to fit a lot of text into a compact, lightweight book without the print showing through from the other side.

- Bible Paper (or India Paper): This is the classic choice for a reason. It’s incredibly thin and light (often 28-40 gsm) but surprisingly strong and opaque. It’s perfect for creating a substantial book that doesn’t feel bulky.

- Lightweight Offset Paper: This is a more common and cost-effective alternative. A weight of around 50-70 gsm works well. An uncoated finish gives it a natural, classic feel that is easy on the eyes, which is vital for a book that is read frequently. I always recommend asking about FSC-certified options, as sustainability is a key consideration for many brands today.

Cover Material Options

The cover is what protects the sacred text and provides the book’s identity. The choice here depends heavily on budget, intended use, and desired aesthetic.

| Material | Pros | Cons | Best For |

|---|---|---|---|

| Genuine Leather | Premium feel, very durable, ages beautifully | Most expensive, requires special care | Heirloom editions, special gifts, clergy copies |

| Faux Leather (PU) | Cost-effective, durable, wide color range | Less breathable, doesn’t age like real leather | Large-scale distribution, congregational use |

| Book Cloth (Linen) | Classic, elegant texture, durable when treated | Can be prone to staining if not laminated | Traditional hymnals, classic library editions |

| Hardcover (Paper) | Highly customizable with printing, economical | Less luxurious feel than other options | Modern designs, youth prayer books, event giveaways |

What Binding Methods Ensure a Prayer Book Lasts a Lifetime?

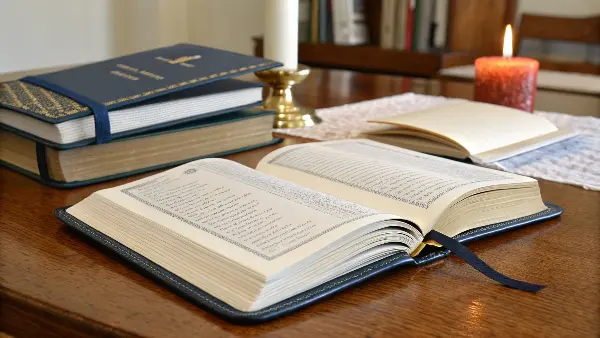

A prayer book is used daily, opened and closed thousands of times. If the binding breaks, the pages fall out, and the book becomes useless. This is frustrating for the user and reflects poorly on its quality. A weak spine means a short life, undermining the book’s purpose as a lasting companion. Let’s talk about binding that is built to endure this constant use.

To ensure a prayer book lasts a lifetime, Smyth-sewn binding is the superior choice. This method involves stitching signatures (groups of pages) together before gluing them to the cover spine. This creates a highly durable book that can lay flat when opened, making it easy to read and handle during prayer. While more expensive than perfect binding, its longevity makes it ideal for sacred texts.

I’ve had many discussions about the trade-offs between cost and quality, and binding is where the long-term value really shows. For a book that’s meant to be a permanent fixture, investing in a superior binding method is non-negotiable. It’s the "bones" of the book, and strong bones are essential for a long life.

The Gold Standard: Smyth-Sewn Binding

This method is the hallmark of high-quality book production. Here’s how it works: the book’s pages are printed on large sheets, which are then folded into small sections called "signatures" (usually 16 or 32 pages). A specialized machine then sews through the fold of each signature, stitching them together. This block of sewn signatures is then glued to the spine of the cover.

The two main advantages are:

- Durability: The stitched spine is incredibly strong. Pages will not fall out, even after decades of use. This is the most durable bookbinding method available.

- Lay-Flat Capability: Smyth-sewn books open and lay flat on a table or lectern without the need to hold them down. This is incredibly practical for hands-free reading during services or personal prayer.

Other Binding Options

While Smyth-sewn is ideal, other methods exist. It’s important to understand their limitations for a project like a prayer book.

- Perfect Binding: This is common for paperbacks. The pages are stacked, and the spine edge is glued directly to the cover. It’s much cheaper but also much less durable. The spine is rigid, and the book won’t lay flat. Over time, the glue can become brittle, and pages can fall out. I would never recommend this for a prayer book intended for daily use.

- Case Binding: This term often describes any hardcover book. A case-bound book can be either Smyth-sewn or perfect-bound. A Smyth-sewn case-bound book is the ultimate combination of a durable interior and a protective hardcover. A perfect-bound case-bound book is stronger than a paperback but still lacks the flexibility and longevity of sewing.

How Can Finishing Touches Elevate a Prayer Book’s Design?

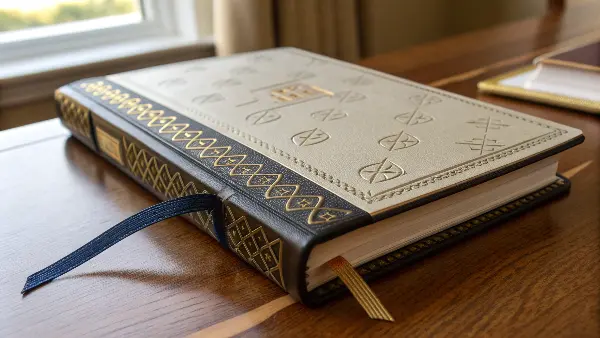

You’ve chosen great materials and a strong binding, but the book still looks plain. A simple cover doesn’t communicate the special nature of the text inside. This missed opportunity can make the prayer book feel generic and impersonal. Without the right embellishments, the design may fail to connect with its audience on an emotional level.

Finishing touches are what transform a well-made book into an object of beauty and reverence. Techniques like foil stamping, debossing, and gilding add elegance and tactile appeal. Foil stamping applies metallic or colored foil for titles and symbols, while debossing creates an indented impression in the cover. Gilded edges add a classic, luxurious look, and ribbon markers provide practical functionality, elevating the user experience.

In my experience, these final details are what people remember. They add a sensory dimension to the book—the way the gold catches the light, the feel of an indented cross under your fingertips, the smooth shimmer of the page edges. These aren’t just decorations; they are signals of quality and care.

Key Finishing Techniques

Let’s break down the most popular and effective options for prayer books.

- Foil Stamping: This process uses heat and pressure to apply a thin layer of metallic or pigmented foil to the cover. Gold and silver are classic choices for religious texts, perfect for titles, crosses, or other sacred symbols. It provides a bright, reflective finish that immediately signals importance.

- Debossing & Embossing: These techniques alter the surface of the cover material.

- Debossing: A metal die is used to press a design into the cover, creating a recessed impression. It provides a subtle, elegant, and tactile feel.

- Embossing: The opposite of debossing, this process pushes a design up from the surface, creating a raised effect. It’s less common on prayer books than debossing but can be used for dramatic effect.

- Gilding: This is the process of applying a thin layer of metallic foil (often gold or silver) to the edges of the book’s pages. It not only looks beautiful and luxurious but also helps protect the pages from moisture and dust over time.

- Ribbon Markers: A simple but essential feature. One or more silk or satin ribbons bound into the spine allow users to mark their place easily. For prayer books with different sections, using multiple ribbons in different colors is a very practical touch.

When combined, these elements create a cohesive and thoughtful design. For example, a navy blue faux leather cover with a simple gold foil debossed cross and a matching gold ribbon marker is a timeless and powerful combination.

What Are the Key Steps in the Prayer Book Customization Process?

You have a vision for a unique prayer book, but you’re not sure how to make it a reality. Navigating the world of custom manufacturing can be complex. You might worry about communication issues, quality control, and whether the final product will match your exact specifications. Without a clear process, a great idea can get lost in translation.

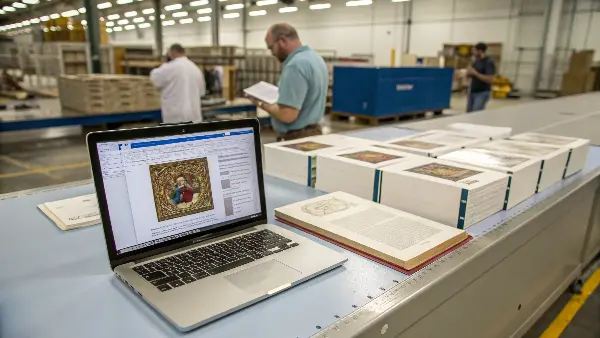

A successful prayer book customization process starts with a detailed brief outlining your vision, including materials, dimensions, and artwork. Next, your manufacturing partner creates digital proofs and physical samples for your approval. Once the sample is perfect, a pre-production check ensures all materials are ready. Production then begins, followed by rigorous quality control before the books are finally packaged and shipped according to your logistics plan.

As a supplier, my job is to make this process smooth and predictable. A good partner acts as a guide, providing clear communication and checkpoints at every stage. I always tell my clients that there should be no surprises. The key is a structured, collaborative workflow that ensures the final product is exactly what they envisioned, from the first design file to the final delivery.

A Step-by-Step Guide to Custom Production

Here is the typical workflow I use with clients to bring their custom prayer book projects to life. This structured approach helps manage expectations and guarantees a high-quality outcome.

-

Initial Consultation and Briefing: It all starts with your idea. You provide us with your specifications: book size, page count, desired paper and cover materials, binding style, and finishing touches. Most importantly, you provide the finalized text and any artwork files for the cover.

-

Quotation and Timeline: Based on your brief, we provide a detailed quotation that breaks down the cost per unit and outlines a projected timeline for sampling, production, and shipping. This transparency is crucial for budgeting and planning.

-

Proofing and Sampling:

- Digital Proofs: We first create digital mockups (PDFs) of the cover and interior layout for you to review and approve. This is the stage to catch any typos or layout errors.

- Physical Sample: Once digital proofs are approved, we produce a physical prototype. This is the most critical step. You get to hold the book, feel the paper, see the colors, and test the binding. This sample must be approved before we proceed to mass production.

-

Mass Production: With the approved sample as our guide, full production begins. Our teams oversee every stage, from printing and folding to sewing, casing-in the covers, and applying the finishing touches.

-

Quality Control: We implement strict quality control checks throughout the production run. We inspect for printing consistency, binding strength, cover alignment, and finishing quality. A final inspection is performed on a percentage of the finished books to ensure they meet the agreed-upon standards.

-

Packaging and Logistics: The books are carefully packed to prevent damage during transit. We work with you to handle shipping and customs clearance, ensuring a smooth delivery to your warehouse or distribution center anywhere in the world.

Conclusion

Creating a prayer book is about much more than just printing words on a page. It’s about crafting a durable, beautiful, and meaningful object. By carefully selecting the right paper, cover materials, binding, and finishing touches, you can produce a book that truly honors its sacred content and serves its community for years, if not generations, to come.