Planning to publish a Bible but feeling lost in a sea of unknown costs? You know quality is non-negotiable, but a vague budget can sink the entire project before it starts. Without a clear breakdown, you risk overspending, cutting corners on vital features, or facing unexpected invoices that derail your mission.

The final cost of producing a Bible is determined by five key factors: material choices (paper and cover), printing method, binding and finishing, quantity, and logistics. Key expenses include specialized thin paper (28-40 gsm), durable cover materials like leather or hardcover, intricate binding such as Smyth-sewn, and finishing touches like gilding. For a standard project, materials and printing make up about 60-70% of the cost, with binding, finishing, and shipping accounting for the rest.

Understanding these costs is the first step toward creating a beautiful, durable Bible that fits your budget. For years, I’ve worked with publishers and organizations to navigate the manufacturing process. It’s a journey with many variables, but each one can be planned for. This guide will break down every element of Bible production costs, helping you make informed decisions and find a partner who can bring your vision to life, on time and on budget. Let’s get into the details.

How Do Material Choices Impact Your Bible’s Final Cost?

You’ve envisioned a beautiful Bible, but the materials feel like a major budget puzzle. Choosing the wrong paper could make it bulky and hard to read, while a cheap cover might undermine its perceived value and longevity. You worry that premium materials will be too expensive, but compromising could hurt the final product.

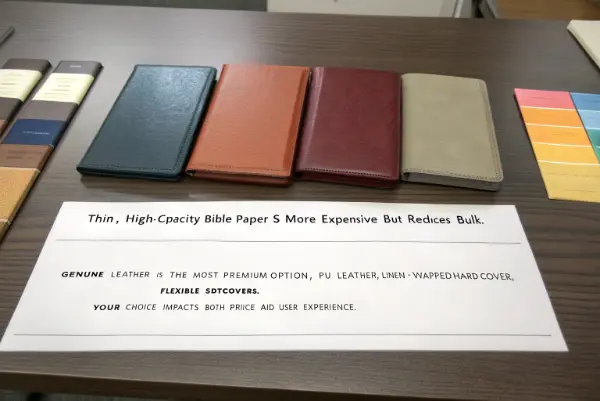

Material choices are a primary cost driver. For paper, thin, high-opacity "Bible paper" (28-40 gsm) is more expensive than standard book paper but essential for reducing bulk. For the cover, genuine leather is the most premium option, followed by polyurethane (PU) leather, linen-wrapped hardcover, and finally, flexible softcovers. Your choice directly impacts both the per-unit price and the user’s tactile experience. The key is to balance cost with the desired quality and durability for your audience.

Choosing the right materials is about more than just numbers; it’s about defining the character of the Bible you want to create. When I work with clients like Michael, a product manager for a European brand, his first questions are always about the look and feel. He knows his customers value aesthetics and durability equally. Let’s break down how these choices affect your budget.

Paper: The Foundation of Readability

The paper inside a Bible is unique. It must be incredibly thin to accommodate over a thousand pages, yet opaque enough to prevent text from bleeding through. This specialized paper, often called Scritta or India paper, is a significant cost factor.

- Weight (GSM): Standard book paper is 80-120 gsm. Bible paper is typically 28-40 gsm. The thinner the paper, the higher the technical requirements for manufacturing, and often, the higher the cost.

- Opacity: Higher opacity prevents "ghosting," where you see the text from the other side. Achieving high opacity in thin paper requires specific pulp and fillers, adding to the expense.

Cover: The First Impression

The cover does more than protect the pages; it communicates the Bible’s value and is the first thing your reader will touch.

| Material Type | Relative Cost | Durability | Perceived Value | Best For |

|---|---|---|---|---|

| Genuine Leather | Very High | Very High | Premium | Heirloom editions, high-end gifts |

| PU Leather | High | High | High | Daily use, premium retail |

| Linen Hardcover | Medium | Good | Classic, academic | Study Bibles, pew Bibles |

| Paperback/Softcover | Low | Low | Accessible | Outreach, bulk distribution |

The choice between these materials can change your per-unit cost dramatically. For a large run, the difference between a softcover and a PU leather cover could amount to tens of thousands of dollars. It’s crucial to align your material choice with your target audience and retail price point from the very beginning.

How Do Printing and Binding Methods Affect the Budget?

You need to print thousands of Bibles, but the technical jargon is confusing. Should you use offset or digital printing? Smyth-sewn or perfect binding? Making the wrong choice could mean paying too much per unit or ending up with books that fall apart after a few months of use, damaging your reputation.

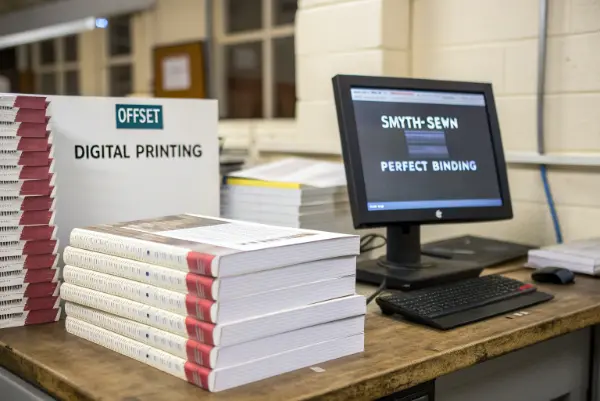

Offset printing is the most cost-effective method for large quantities (typically over 1,000 units), offering the lowest per-unit price. For binding, Smyth-sewn is the gold standard for Bibles; it allows the book to lay flat and is extremely durable but costs more than perfect binding, which is a glued-spine method better suited for low-cost, lower-use books. Your choices here create a trade-off between upfront investment, per-unit cost, and long-term quality.

I once had a client who wanted to produce a small batch of 500 premium study Bibles. They were initially quoted for offset printing, which seemed expensive. We switched their project to digital printing, which had a higher per-unit cost but avoided the high setup fees of offset, saving them money on that smaller run. The binding, however, remained Smyth-sewn—we agreed quality couldn’t be compromised there. It’s all about matching the method to the project’s scale and purpose.

Printing: Finding the Sweet Spot for Your Quantity

The number of Bibles you plan to produce is the single most important factor when choosing a printing method.

- Offset Printing: This traditional method uses plates to transfer ink to paper. It has high initial setup costs, but once the press is running, the cost per book becomes very low. It’s the only logical choice for runs in the thousands or tens of thousands.

- Digital Printing: This method works more like a desktop printer, with no plates involved. It has almost no setup cost, making it ideal for small quantities or print-on-demand services. However, the cost per book remains static, making it very expensive for large runs.

Binding: Ensuring Your Bible Lasts a Lifetime

How a Bible is held together determines how it feels to use and how long it will last.

| Binding Method | Lay-Flat Ability | Durability | Relative Cost | Best Use Case |

|---|---|---|---|---|

| Smyth-Sewn | Excellent | Very High | High | All quality Bibles, especially study or daily-use editions |

| Section-Sewn | Good | High | Medium-High | A good alternative to Smyth-sewn for hardcover books |

| Perfect Binding | Poor | Low | Low | Low-cost paperback Bibles, outreach materials |

| Case Binding | N/A | Very High | High | This refers to the hardcover itself, almost always used with Smyth-sewn pages |

For a book meant to be read, referenced, and cherished for years, Smyth-sewn binding is not a luxury; it’s a necessity. The pages are stitched together in signatures, allowing the Bible to open and lay flat without breaking the spine. While perfect binding is cheaper, a glued spine will eventually crack, and pages will fall out—a fatal flaw for a book intended for daily use.

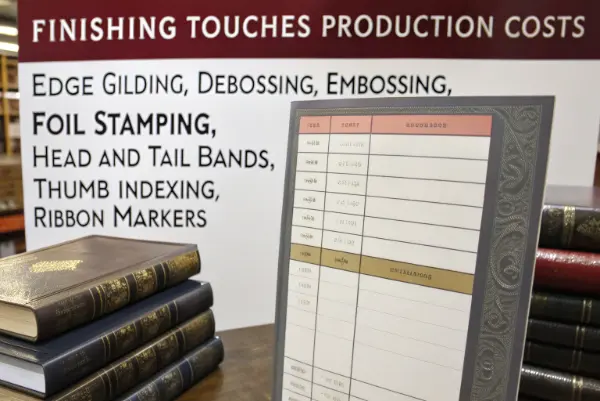

What Finishing Touches Add to the Production Cost?

You’re close to finalizing your Bible’s design, but what about the small details? Things like gilded edges, ribbon markers, and debossed covers seem important, but you’re not sure how much they add to the budget. You’re afraid of either missing an opportunity to elevate your product or adding features that unnecessarily inflate the cost.

Finishing touches can significantly enhance a Bible’s perceived value but add incremental costs. Edge gilding (gold or silver foil) is a costly but popular feature. Debossing, embossing, and foil stamping on the cover add texture and elegance but require custom dies. Other additions like head & tail bands, thumb indexing, and multiple ribbon markers each contribute to the final per-unit price. It’s best to prioritize these features based on your audience’s expectations.

When developing a new line of gift Bibles, my client Michael was adamant about including two ribbon markers instead of one. He argued that for a study Bible, users needed to mark both the Old and New Testaments. It was a small additional cost, maybe only a few cents per book, but it dramatically improved the user experience. This is the kind of thoughtful detail that separates a good product from a great one. These finishing touches are where you can truly tailor the final product.

Elevating the Aesthetics and Functionality

Each finishing detail serves a purpose, whether it’s purely for beauty or for practical use. Understanding their cost impact helps you decide what’s essential and what’s a "nice-to-have."

-

Edge Treatment: This is one of the most noticeable finishes.

- Gilding: Applying metallic foil (gold, silver, copper) to the page edges. It’s a specialized process that adds a premium feel but also a notable cost.

- Art Gilding / Edge Staining: Staining the edges with a color, sometimes with a design. It’s a modern, stylish alternative to gilding and can be slightly less expensive.

-

Cover Decoration: How you brand and decorate the cover is key.

- Debossing/Embossing: Pressing a design into the cover material (debossing) or raising it (embossing). This requires creating a custom metal die, which has a one-time setup fee.

- Foil Stamping: Using heat and pressure to apply metallic foil for text or logos. It offers a classic, high-end look.

Adding Practical Features

These small additions make the Bible more user-friendly.

| Feature | Primary Function | Relative Cost Impact | Is It Worth It? |

|---|---|---|---|

| Ribbon Markers | Page marking | Low | Yes, almost essential. Two is better than one for study Bibles. |

| Thumb Indexing | Quick navigation | Medium | Very useful for reference or study Bibles, but adds a complex cutting process. |

| Head & Tail Bands | Decorative/Spine reinforcement | Very Low | A standard feature on most quality hardcover books; adds a professional touch. |

| Presentation Pages | Gifting and personalization | Low | Essential for gift editions. Adds a few pages of heavier, coated paper at the front. |

Ultimately, the right combination of finishes depends on your goals. For a bulk outreach Bible, a simple foil-stamped title on a softcover is enough. For a premium gift Bible, gilded edges, two ribbon markers, and a debossed leather cover are practically expected.

Are There Hidden Costs in Bible Manufacturing You Should Know About?

You’ve budgeted for materials, printing, and binding, but what else is lurking? The fear of unexpected charges for shipping, tariffs, or setup fees can be stressful. A surprise invoice for something you didn’t plan for can ruin your profit margins and delay your entire project, leaving you frustrated and over budget.

Yes, several "hidden" costs exist beyond the per-unit price. These include one-time setup fees for printing plates and cover dies, costs for physical proofs and prototypes, and significant expenses for freight, customs duties, and taxes. Fluctuating currency exchange rates can also impact your final bill. A transparent manufacturing partner will itemize these for you upfront, but you must always budget an extra 10-15% for logistics and unforeseen expenses.

I always tell my clients to separate the "ex-factory" price (the cost to make one unit at the factory) from the "landed cost" (the cost to get that unit into your warehouse). A few years ago, a nonprofit I worked with was thrilled with a low per-unit quote from a new supplier. But they hadn’t factored in shipping from Asia to the US during peak season or the 15% import tariff. Their landed cost ended up being 40% higher than the factory price, completely wrecking their budget. It’s a hard lesson to learn, which is why we always build a complete cost model from day one.

From Factory Floor to Your Warehouse

The journey doesn’t end when the printing press stops. Getting thousands of books from a factory in another country to your distribution center is a complex and costly process.

-

Pre-production Costs:

- Tooling/Plate Fees: Offset printing requires new plates for every project. Custom debossing or foil stamping requires a new die. These are one-time costs, but they can be several hundred to a few thousand dollars.

- Prototyping: You’ll want to see and approve a physical sample before mass production begins. While some suppliers include one, extra revisions or multiple prototypes will cost you.

-

Logistics and Shipping:

- Freight: This is a major expense. Ocean freight is cheaper but slower (4-6 weeks). Air freight is very fast but can cost 5-10 times more. The choice depends on your timeline.

- Insurance: You must insure your shipment against loss or damage during transit.

Navigating Customs and Taxes

This is where many first-time importers get into trouble.

| Hidden Cost | Description | How to Manage It |

|---|---|---|

| Customs Duties/Tariffs | Taxes imposed by your country on imported goods. Varies wildly by country and product category. | Work with a customs broker or a supplier who understands your country’s import laws. Get a tariff code (HS Code) for your product early. |

| VAT / Sales Tax | Taxes applied upon import, which may or may not be reclaimable depending on your business status. | Consult your accountant to understand the tax implications in your country. |

| Port & Handling Fees | Local charges at both the export and import ports for handling, documentation, and storage. | Your freight forwarder should provide a quote that includes these, but always ask if it’s "all-in." |

| Currency Fluctuation | If you’re paying in a foreign currency (e.g., USD or CNY), the final cost in your local currency can change between the quote and the final payment. | Discuss payment terms with your supplier. Some may offer to fix the price in your currency. |

A reliable manufacturing partner won’t hide these costs. They will provide a clear, itemized quote and help you plan for the full landed cost. Always ask, "Does this price include everything to get the books to my door?"

Conclusion

In the end, producing a Bible is a detailed process where every choice, from paper thickness to shipping methods, shapes the final cost. By understanding the key drivers—materials, printing, binding, finishing, and logistics—you can move from budget uncertainty to confident, strategic planning, ensuring your project’s success.