Are you looking for ways to make your notebooks and journals stand out in a crowded market? It’s frustrating when your beautiful designs are bound in a product that feels plain or unfinished. By ignoring the book’s edge, you’re missing a key opportunity to add value and create a product that truly captivates your customers.

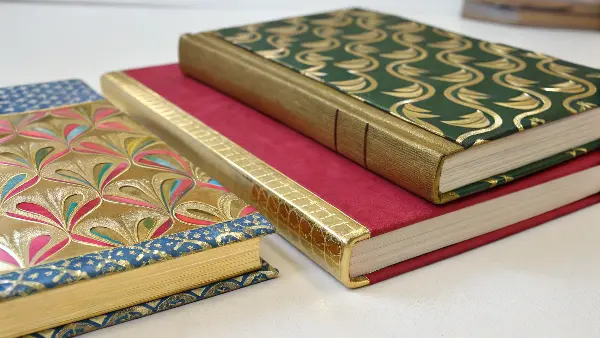

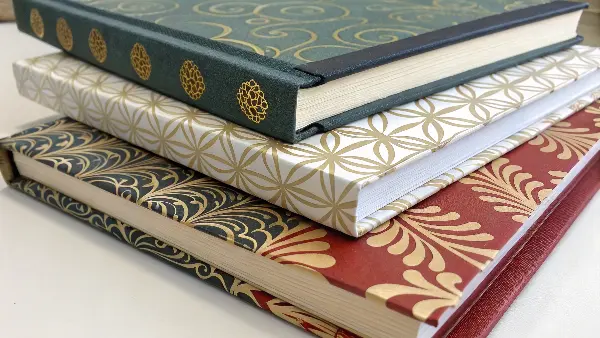

The main book edge decoration techniques are gilding, spraying, and special effects. Gilding involves applying metallic foil for a luxurious, classic look. Spraying, or edge painting, adds a solid block of vibrant color. Special effects encompass more advanced methods like intricate stenciling, applying patterned foils, digital printing with full-color graphics, or traditional marbling. Each technique transforms a standard book into a premium, eye-catching piece that commands attention and a higher price point.

These beautiful finishes might seem complex, but they are all based on precise manufacturing processes that combine craftsmanship with technology. Understanding how they work is the first step toward incorporating them into your own product line. It opens up a new world of design possibilities that can set your brand apart. Let’s pull back the curtain and explore how these stunning effects are created, starting with what we even call these processes.

What is it called when you paint the edges of a book?

You’ve seen beautifully crafted books with solid colored edges that perfectly match their covers, but what is this technique called? When you’re trying to communicate a specific design vision to a supplier, not knowing the right terminology can be a real roadblock. This uncertainty can lead to misunderstandings, incorrect samples, and frustrating delays in production.

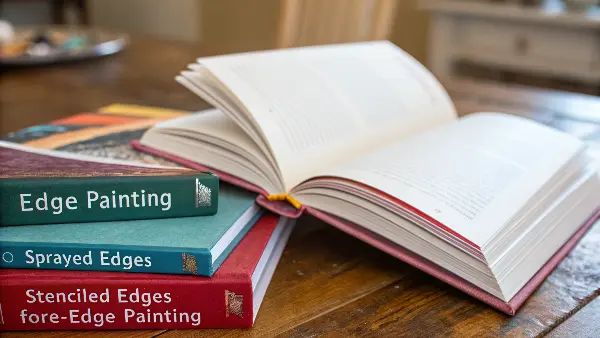

In the industry, the general term for adding color to a book’s edge is "edge painting" or "edge staining." When the color is applied with an atomizer for a smooth, even finish, it is most commonly known as "sprayed edges." This is the most popular commercial method. For more detailed designs, you might hear terms like "stenciled edges" for patterns or the traditional art form of "fore-edge painting" for hidden, intricate images. Knowing these terms ensures your specifications are clear and accurate.

The term you use really depends on the effect you want to achieve. While "edge painting" is a good catch-all, being specific helps everyone. I remember a client from the UK who was developing a new line of high-end planners. She kept asking for "painted edges" and sent us reference photos of journals with intricate floral patterns along the side. We quickly realized that what she wanted wasn’t a simple, solid color spray. She was actually looking for "stenciled edges" or even a digitally printed edge. By clarifying the terminology right at the start, we avoided weeks of back-and-forth and incorrect sampling. We moved straight to developing a custom stencil that matched her brand’s floral motif, and the final product was exactly what she envisioned.

To make it clearer, here’s a simple breakdown of the common terms:

| Term | Description | Common Use Case |

|---|---|---|

| Edge Painting / Staining | A general term for applying any kind of color to the book block’s edges. | Journals, special edition fiction, custom notebooks. |

| Sprayed Edges | A specific method using a spray gun for even, solid color application. | Mass-market hardcovers, premium B2B stationery. |

| Stenciled Edges | Using a stencil with spray paint to create repeating patterns or designs. | Limited edition book sets, designer stationery lines. |

| Fore-edge Painting | An artistic, often-hidden painting on the edges, visible only when fanned. | Highly valuable collectible books, artisan crafts. |

Understanding this vocabulary is the first step in unlocking creative possibilities for your products.

What is a gilded book edge?

You want to create a product that feels timeless, luxurious, and significant. For a premium collection or a special gift set, a standard notebook with plain paper edges just doesn’t convey the right message. Without that extra touch of elegance, your product risks getting overlooked, as customers often associate small, refined details with overall quality and value.

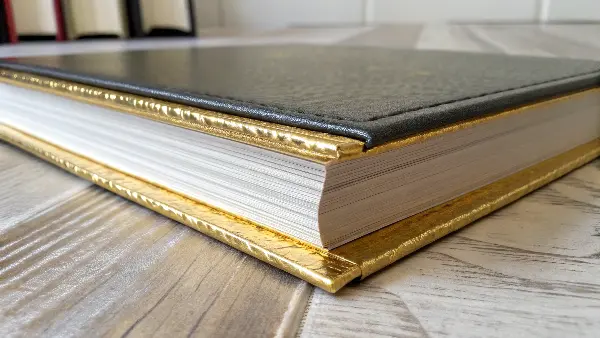

A gilded book edge is a classic decorative finish where a thin layer of metallic foil is applied to the edges of the pages. Traditionally done with real gold leaf, modern commercial gilding often uses imitation gold, silver, copper, or colored metallic foils. This process creates a brilliant, mirror-like finish that not only looks incredibly elegant but also serves a practical purpose by helping to protect the paper from dust and moisture. It instantly signals premium quality and craftsmanship.

The appeal of gilding is deeply rooted in history. For centuries, it was reserved for sacred texts and important manuscripts, a visual cue that the object was valuable and worthy of preservation. That psychological association still exists today. When a customer sees a journal with a gilded edge, they instinctively perceive it as a higher-quality, more permanent object. It’s a small detail that carries a lot of weight.

Beyond aesthetics, gilding has practical benefits. The process compresses the paper edges and seals them with a non-porous metallic layer. This helps protect the pages from absorbing humidity, which can cause yellowing or warping over time. It also prevents dust from settling between the pages.

At Panoffices, we’ve taken this traditional technique and adapted it for the modern market. Gilding is no longer just about classic gold. We work with clients to create notebooks with stunning rose gold, sleek matte black, or even vibrant holographic gilded edges. Imagine a minimalist, all-black notebook that reveals a flash of electric blue foil on the edge when opened. It’s a surprising and delightful detail that can make a product unforgettable. This blend of classic technique with modern style is a powerful way to elevate a simple stationery item into a coveted design object.

How to gild the edges of books?

You’ve decided that gilded edges are the perfect high-end touch for your next product line. But the manufacturing process can seem like a black box. How can you be sure your supplier will deliver a clean, durable, and flawless finish? A lack of understanding can lead to disappointing results, like flaking foil, uneven color, or pages that are stuck together—a quality control nightmare.

To gild book edges, the book blocks are first trimmed and sanded to a perfectly smooth, glass-like surface. Next, they are clamped together under immense pressure to form a single, solid block. A special adhesive sizing is thinly applied to the edge. Finally, a sheet of metallic foil is placed over the adhesive, and a heated press or roller applies heat and pressure. This bonds the metallic layer to the paper edges, and after cooling, the excess foil is brushed away to reveal the brilliant finish.

The quality of a gilded edge depends entirely on the precision of each step. There are no shortcuts. Here’s a closer look at the process we follow to ensure a perfect result every time:

- Preparation and Trimming: It all starts with the book block. The pages must be perfectly aligned and trimmed with a guillotine cutter to create a single, flush surface. Any unevenness at this stage will be magnified in the final product.

- Sanding: This is perhaps the most critical step for achieving a mirror-like shine. The trimmed edge is sanded with progressively finer grits of sandpaper until it is completely smooth and free of any paper fibers. If this step is rushed, the final gilded edge will look dull or textured.

- Clamping: We stack the sanded book blocks and place them in a powerful hydraulic press. The pressure is immense, compacting the pages so tightly that the edge behaves like a solid piece of wood. This prevents any adhesive from seeping between the pages. I’ve seen jobs from other suppliers where improper clamping led to entire batches of books with pages glued shut.

- Sizing and Foil Application: A thin, even layer of specialized adhesive, known as sizing, is applied to the compacted edge. Then, the metallic foil is laid on top. The book block is then placed in a gilding machine that uses a heated silicone roller or a flat press. The combination of controlled heat and pressure activates the sizing and transfers the foil’s metallic layer onto the paper.

- Finishing: After the block has cooled, the books are unclamped. The excess foil is gently brushed away, leaving behind only the perfectly bonded metallic edge. We then inspect each book for imperfections like flaking, dark spots (from uneven sizing), or dull areas before moving to the final binding stage.

How are sprayed edges done on books?

Adding a bold pop of color to your book edges is a fantastic way to catch the eye, but you might be worried about quality and consistency, especially for a large production run. How do you ensure the color is vibrant, the lines are crisp, and the ink doesn’t bleed into the pages? A sloppy spray job can make an otherwise premium product look cheap and unprofessional.

To create sprayed edges, stacks of book blocks are first clamped under high pressure, which compacts the pages into a single, non-porous surface. Inside a specialized spray booth, a skilled operator uses a spray gun to apply thin, even coats of custom-formulated ink onto the edges. The high pressure and fine mist ensure deep color saturation without bleed-through. After application, the blocks are left to dry completely in a controlled environment before being unclamped.

The process for creating sprayed edges is all about control and precision. While it sounds straightforward, achieving a perfect, professional finish requires specialized equipment and expertise. Like with gilding, the first step is clamping the book blocks tightly in a press. This is non-negotiable. The pressure is what prevents the ink from wicking between the paper fibers and creating a messy, bleeding effect.

Once clamped, the blocks are taken to a ventilated spray booth. The ink we use isn’t just standard paint; it’s a specially formulated, fast-drying ink designed to adhere to paper edges. A key part of our service at Panoffices is our ability to perform precise color matching. Our clients can specify a Pantone color from their brand guide, and we create a batch of ink to match it perfectly. This ensures brand consistency across their entire product line.

The application itself is a skill. The operator must maintain the right distance and move the spray gun at a consistent speed to apply a uniform coat. Multiple thin coats are better than one thick coat, as this prevents drips and ensures a richer, more saturated color. After spraying, the blocks are moved to a drying area where temperature and humidity are controlled to ensure the ink cures properly without smudging. Only when they are completely dry can the pressure be released. It’s a meticulous process, but it’s what allows us to produce thousands of books with consistently sharp, vibrant edges.

What Other Special Effects Can Be Applied to Book Edges?

You’ve mastered solid colors and classic metallics, but you’re an innovator. You’re looking for that next-level detail that will make your stationery a true market leader. How can you push the creative boundaries of edge design? Sticking only to the basics is safe, but it also means you might be missing out on the trends and techniques that create truly memorable, "must-have" products.

Beyond standard gilding and spraying, a range of special effects can turn book edges into a canvas for art. These include "stenciled edges" or "foiled edges" for repeating patterns, "digital edge printing" which applies full-color photos or intricate graphics directly onto the side, and "marbled edges," a traditional craft that gives each book a unique, swirling pattern. These advanced techniques offer unparalleled opportunities for customization and branding, creating truly one-of-a-kind products.

Exploring these advanced options can be incredibly rewarding. We’ve worked with some of our more adventurous clients to create some amazing products using these methods.

- Stenciled and Patterned Foiled Edges: This is a step up from a solid finish. For stenciling, we create a custom die-cut stencil of a logo or pattern. When ink is sprayed over it, the design is transferred onto the book edge. Patterned foiling works similarly, but uses a heated die to stamp a patterned or holographic foil onto the edge. This is perfect for adding subtle branding or a playful, geometric design.

- Digital Edge Printing: This is where things get really exciting. Using specialized inkjet technology, we can print high-resolution, full-color images directly onto the clamped book edge. Imagine a travel journal with a world map printed on the side, a cookbook with a photo of the book’s signature dish, or a special edition novel with a key scene illustrated across the pages. The possibilities are nearly endless and offer a level of customization that was previously unimaginable.

- Marbled Edges: For the ultimate artisanal touch, there is marbling. This is a centuries-old craft where paints are floated on a liquid surface and swirled into patterns. The book edge is then carefully dipped into the liquid, transferring the unique pattern onto the paper. Because of the fluid nature of the process, no two marbled edges are ever exactly alike. It’s a labor-intensive and costly process, but for a truly luxurious, limited-edition product, its unique beauty is unmatched.

Here is how these techniques compare:

| Technique | Vibe | Best For | Cost/Complexity |

|---|---|---|---|

| Stenciled Edges | Graphic, Modern | Branded notebooks, patterned planners. | Medium |

| Patterned Foiling | Playful, Luxe | Special editions, trendy gift items. | Medium-High |

| Digital Edge Printing | Highly Custom, Artistic | Premium collector’s editions, concept books. | High |

| Marbled Edges | Artisanal, Unique | Bespoke journals, high-end limited runs. | Very High |

Conclusion

From the timeless elegance of gilding to the bold statement of a sprayed edge and the incredible artistry of digital printing, edge decoration is a powerful design tool. Understanding these different techniques empowers you to think beyond the cover, allowing you to create products that not only stand out on the shelf but also offer a unique and memorable experience for your customer.