Choosing a book cover is a huge decision. You’ve poured everything into the pages, but the cover is what makes the first impression. Get it wrong, and a potential reader might just walk on by, never discovering the great content inside. It’s a lot of pressure to get it right.

The best book cover material depends on your book’s purpose, audience, and budget. For paperbacks, coated paper stock between 240-300 GSM offers a great balance of durability and quality. For hardcovers, a 2-3mm greyboard wrapped in art paper, book cloth, or faux leather provides a premium and sturdy feel. The choice is guided by desired aesthetics, durability, and cost-effectiveness, ensuring the cover aligns perfectly with your brand and market.

Making the right choice can feel overwhelming with so many options available. You have to think about paper weights, finishes, durability, and how it all fits within your budget. It’s more than just picking a pretty design; it’s a technical decision that impacts the final product’s look, feel, and perceived value. But don’t worry, breaking it down makes it much simpler. Let’s explore the options so you can choose with confidence.

What are the most common types of paper for softcovers?

Struggling to decide on the perfect paper for your paperback? The sheer number of options, from gloss to matte and various thicknesses, can be confusing. Choosing the wrong one can make your book feel cheap or not durable enough for readers, undermining all your hard work.

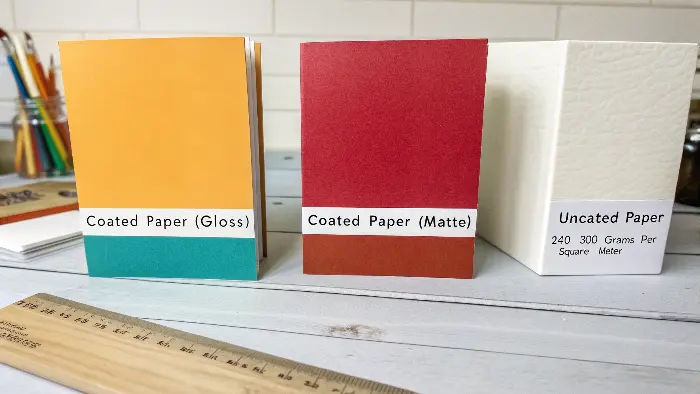

The most common paper types for softcovers are coated and uncoated stocks. Coated paper (with a gloss or matte finish) is typically preferred for its vibrancy and durability, with weights from 240 to 300 GSM (grams per square meter) being standard. Uncoated paper offers a more natural, textured feel, suitable for literary or artistic books. The choice hinges on the desired aesthetic and the book’s genre.

When we talk about softcover books, also known as paperbacks, the cover stock is everything. It needs to be flexible yet strong enough to withstand handling. As a supplier, I’ve helped countless clients navigate these choices. The decision usually comes down to two key factors: the paper’s coating and its weight.

Coated vs. Uncoated Stock

Coated paper has a sealant, typically clay-based, that fills in the tiny pits of the paper’s surface. This makes it smooth and less absorbent, so ink sits on top. The result? Sharper, more vibrant images and text. This is why it’s the go-to for commercial fiction, photo-heavy books, and anything that needs to pop on the shelf. It comes in two main flavors:

- Gloss: Shiny and reflective, making colors look rich and deep. Great for grabbing attention.

- Matte: A smooth, non-shiny finish that looks more subtle and sophisticated. It’s less prone to showing fingerprints than gloss.

Uncoated paper, on the other hand, has a more natural, porous texture. Ink soaks into the paper more, which can give colors a softer, more muted look. It feels more organic and is often chosen for literary fiction, poetry, or journals where a tactile, understated feel is desired.

Paper Weight (GSM)

Paper weight is measured in Grams per Square Meter (GSM). A higher GSM means a thicker, heavier, and more durable paper.

| GSM Range | Typical Use Case | Feel & Durability |

|---|---|---|

| 190-230 GSM | Mass-market paperbacks, booklets | Flexible, lower durability. Best for low-cost projects. |

| 240-300 GSM | Trade paperbacks, premium journals | The industry standard. Sturdy, professional feel. |

| 310-400 GSM | Premium softcovers, art books, business cards | Very thick and stiff. Feels high-end but less flexible. |

For most projects, I recommend a stock around 260-300 GSM. It provides that satisfying, substantial feel without being too rigid, striking the perfect balance for a quality paperback.

How do hardcover materials create a premium feel?

You want to create a hardcover book that feels special and timeless, but you’re not sure where to start. Unlike paperbacks, hardcovers have multiple components, and choosing the wrong combination can result in a book that feels flimsy or looks cheap, failing to justify its higher price point.

Hardcover books create a premium feel through their construction: a thick, rigid board (usually 2-3mm greyboard) is wrapped in a durable material like art paper, book cloth, or faux leather. This combination, known as case binding, provides significant weight, sturdiness, and a superior tactile experience. The addition of decorative endpapers and a dust jacket further enhances its perceived value and durability, signaling a high-quality, long-lasting product.

Hardcovers, or casebound books, are the gold standard for quality and longevity. They are built to last, and their construction is what gives them that distinguished, premium feel. When I work with clients like Michael, who are developing a high-end stationery line, we focus on these components to get the feel just right. The magic is in the "case," which is the outer shell of the book.

The Core: Binder’s Board

At the heart of every hardcover is the board. This isn’t just thick paper; it’s a dense, rigid pressboard, often called greyboard. Its thickness is what gives the cover its unbendable strength.

- 2mm Board: A good standard for smaller to medium-sized books. Provides solid protection without being overly heavy.

- 3mm Board: Used for larger books, like coffee table books or premium ledgers. It adds significant weight and a very robust, high-end feel.

- 4mm Board: Reserved for very large or luxury special editions. It’s extremely rigid and makes a powerful statement.

The Wrap: Covering the Board

The board itself isn’t visually appealing, so it’s wrapped in a cover material. This is where you can define the book’s personality.

| Wrap Material | Description | Best For |

|---|---|---|

| Printed Art Paper | A 120-150 GSM paper is printed with the cover design and then laminated (matte or gloss) for protection before being wrapped around the board. | The most common and versatile option. Allows for full-color, complex graphic designs. |

| Book Cloth | Woven fabric (like linen, cotton, or rayon) that provides a classic, tactile feel. Can be dyed in many colors. | Library editions, classic novels, premium journals, and yearbooks. Evokes tradition and elegance. |

| Faux Leather (PU) | A synthetic material that mimics the look and feel of real leather. It’s durable and can be debossed beautifully. | Business diaries, planners, religious books, and premium notebooks. Offers a sophisticated, professional look. |

The choice of wrap material is a key decision. A printed paper wrap offers unlimited design freedom, while cloth or faux leather provides a texture and elegance that print can’t replicate. For many of our B2B clients, a debossed logo on a faux leather or cloth cover is the very definition of a premium corporate gift.

What special finishes can elevate a book cover?

Your cover design is complete, but it still feels like it’s missing something. You see other books with eye-catching metallic details or raised textures and wonder how to achieve that. Without these finishing touches, your book might look flat and fail to stand out in a crowded market.

Special finishes can dramatically elevate a book cover by adding visual and tactile appeal. Key options include lamination for protection and feel (matte or gloss), spot UV to highlight specific areas with a high-gloss sheen, foil stamping for a metallic effect, and embossing/debossing to create a raised or recessed texture. These techniques make a cover more interactive and memorable, signaling a high-quality product.

After spending so much time on the content and basic design, the finishes are what take a cover from good to great. They are the details that make a person stop and pick up the book. These are some of the most popular techniques we use to add that "wow" factor for our clients. Think of them as the final layer of polish.

Lamination: The Protective Base

Before any other finish, most softcovers and printed hardcover wraps are laminated. This is a thin plastic film applied to the paper. It’s not just for looks; it’s crucial for protection against moisture, scuffs, and tears.

- Gloss Lamination: Creates a shiny, vibrant finish. It makes colors pop but can show fingerprints and glare.

- Matte Lamination: Provides a soft, elegant, non-reflective finish. It feels smooth to the touch and looks very modern.

- Soft-Touch Lamination: A type of matte lamination that has a velvety, almost rubbery texture. It’s incredibly tactile and feels very luxurious.

Adding Targeted Shine and Texture

Once the base lamination is on, you can add more targeted effects.

- Spot UV: This is where a high-gloss UV coating is applied to specific parts of the design—like the title, an author’s name, or a graphic element. On top of a matte lamination, the contrast between the shiny spot UV and the matte background is striking. It invites touch and draws the eye to key details.

- Foil Stamping: This process uses heat and pressure to apply a thin metallic foil to the cover. While gold and silver are classic, foil comes in a huge range of colors, including copper, rose gold, and even holographic effects. It adds a flash of metallic brilliance that instantly communicates luxury.

- Embossing & Debossing: These techniques alter the surface of the paper itself.

- Embossing uses a die to press a design up from underneath, creating a raised 3D effect.

- Debossing presses a design down into the paper, creating a recessed or indented effect.

Both add a sophisticated, tactile quality that makes a cover feel crafted and substantial. A debossed logo on a cloth or faux leather journal is a classic combination.

How does sustainability influence material choices today?

Your customers are increasingly eco-conscious, and you want your products to reflect those values. However, navigating the world of "green" materials can be a minefield of confusing labels and potential greenwashing. Choosing a material that isn’t genuinely sustainable could damage your brand’s reputation.

Sustainability now plays a crucial role in material selection, with a strong market preference for certified and recycled options. Key choices include using FSC-certified paper, which guarantees responsible forest management, and incorporating recycled content (PCW). Furthermore, opting for vegetable or soy-based inks over traditional petroleum-based ones reduces VOC emissions. These choices not only minimize environmental impact but also align with consumer values, enhancing brand image.

In today’s market, especially in Europe and North America, sustainability isn’t just a bonus—it’s a core requirement for many brands and consumers. As a manufacturer, we’ve seen this shift firsthand. Buyers like Michael from Germany often have sustainability as a non-negotiable point on their sourcing checklist. It’s about responsible production from forest to finished product.

Certified and Recycled Paper

The single biggest impact you can make is with your paper choice.

- FSC (Forest Stewardship Council) Certification: This is the gold standard. When you see the FSC logo, it means the paper comes from a forest that is managed in an environmentally and socially responsible way. It ensures that trees are replanted and that the rights of indigenous peoples and local communities are protected. We strongly recommend this for all projects.

- Recycled Content: Paper can be made with pre-consumer or post-consumer waste (PCW). PCW is the better choice, as it diverts paper from landfills. You can specify the percentage of PCW you want, often from 10% to 100%. While 100% recycled paper can have a slightly different texture and brightness, modern recycling processes produce very high-quality paper that is suitable for most book covers.

Beyond the Paper

Sustainability extends beyond just the paper stock.

- Inks: Traditional printing inks are petroleum-based and release Volatile Organic Compounds (VOCs) during the drying process. A more sustainable choice is to use vegetable-based or soy-based inks. They are derived from renewable resources and have much lower VOC levels, making them better for the environment and for the health of the people working in the print shop.

- Lamination: While lamination protects the book, it is a plastic film, which complicates recycling. Some companies are exploring biodegradable or compostable laminations, but they are not yet widely available or as durable. For now, the most sustainable choice is often to opt for an uncoated cover or a durable coated paper without lamination if the project allows.

Making these choices demonstrates a commitment to the planet and can be a powerful part of your brand’s story.

Conclusion

Choosing the right book cover material is a balance of aesthetics, durability, budget, and brand identity. From the versatile papers of softcovers to the robust construction of hardcovers and the final polish of special finishes, each choice helps tell your book’s story before the first page is even turned.