Struggling to print on delicate, ultra-thin paper? The process is fraught with issues like wrinkling, jamming, and ink bleeding through, leading to costly waste and production delays. But what if you could master the techniques for a perfect print every time? Understanding the core challenges and their solutions is the key to turning this difficult task into a repeatable success.

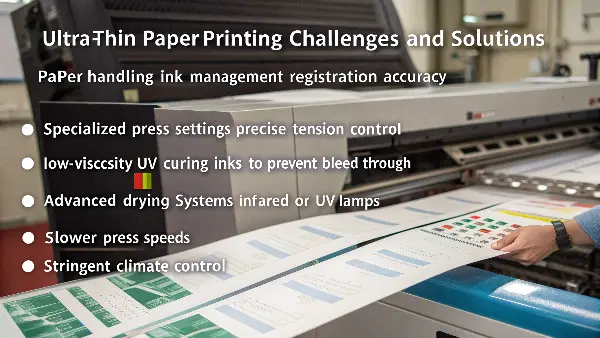

The main challenges in ultra-thin paper printing are paper handling, ink management, and registration accuracy. Key solutions include using specialized press settings with precise tension control, opting for low-viscosity UV-curing inks to prevent bleed-through, and implementing advanced drying systems like infrared or UV lamps. Slower press speeds and stringent climate control are also critical for achieving high-quality, consistent results on lightweight stock.

I’ve spent years working with suppliers on complex projects, and printing on papers below 40 gsm is one of the biggest hurdles we face. It’s a delicate dance between machine, material, and environment. Many clients, like Michael from Germany who develops high-end stationery, demand perfection on these lightweight stocks for products like diaries and luxury notebooks. Getting it wrong isn’t an option. Let’s break down exactly how we get it right, one challenge at a time.

How Can You Master Paper Handling and Prevent Wrinkles?

You’ve sourced a beautiful, delicate, ultra-thin paper, but the moment it hits the press, it turns into a crinkled, jammed mess. This constant battle with the material causes production to grind to a halt, waste to pile up, and your critical deadlines to be put at risk. The secret to success lies in mastering tension control and optimizing your systems specifically for this lightweight stock.

To master paper handling and prevent wrinkles, focus on three areas: web tension, feeder systems, and static electricity. Use precise, minimal tension on roll-fed presses or specialized air-assisted feeders on sheet-fed presses. Employ anti-static bars to ensure sheets separate cleanly. Proper climate control, maintaining stable humidity around 45-55%, is also essential to keep the paper flat, stable, and manageable throughout the printing run.

The physical handling of the paper is the first and often most significant challenge. Unlike standard 80 gsm office paper, ultra-thin stock has very little structural integrity. It behaves more like fabric than paper, making it highly susceptible to environmental changes and mechanical stress. Based on my experience working on projects for demanding clients, a systematic approach to handling is the only way to ensure a smooth production run.

Achieving the Perfect Tension

For roll-fed offset presses, which are common for large-volume jobs like Bibles or pharmaceutical inserts, web tension is everything. Too much tension will stretch or tear the paper. Too little, and you get wrinkles or fluttering, which leads to misregistration. Modern presses use sophisticated systems with dancer rolls and load cells to provide real-time feedback and automatically adjust the tension. We always advise our partners to start at the lowest possible tension setting and gradually increase it until the web is stable. It’s a fine-tuning process that requires an experienced operator.

Optimizing Sheet-Fed Systems

On sheet-fed presses, the challenge shifts to the feeder and delivery systems. Standard friction feeders are too aggressive and will damage the paper. The solution is to use a press equipped with an air-assisted feeder. This system uses a combination of suction and gentle air blasts to separate the top sheet from the stack without scuffing or wrinkling it. Furthermore, we often recommend slowing the press speed down by as much as 30-40%. A slower speed gives the vacuum belts and grippers more time to secure the sheet properly as it travels through the press.

Controlling the Environment

Finally, you cannot ignore the printing environment itself. Thin paper is extremely sensitive to changes in humidity and temperature.

| Environmental Factor | Ideal Range | Impact of Poor Control | Solution |

|---|---|---|---|

| Humidity | 45-55% RH | Paper can become wavy (high humidity) or brittle and static-prone (low humidity). | Use industrial humidifiers/dehumidifiers. |

| Temperature | 20-22°C (68-72°F) | Affects ink viscosity and drying times, indirectly impacting paper. | Maintain a stable, climate-controlled pressroom. |

| Static Electricity | Neutral | Sheets stick together, causing double-feeds and jams. | Install anti-static bars at the feeder and delivery ends of the press. |

Before any print job, we insist that the paper be allowed to acclimate in the pressroom for at least 24 hours. This simple step ensures the paper’s moisture content stabilizes, making it far easier to handle.

What Are the Best Ink and Drying Strategies for Thin Paper?

You’ve finally managed to feed the thin paper through the press without a jam, but now the ink is bleeding through to the other side. This "ghosting" effect creates a blurry mess, ruins the text’s legibility, and makes double-sided printing nearly impossible. It completely compromises the quality and feel of your final product, a major concern for brand-conscious buyers like Michael. The key is using the right ink combined with a carefully controlled drying process.

The best strategy involves using low-viscosity, fast-drying inks to minimize paper saturation. UV-curing or LED-UV inks are ideal as they cure instantly on the surface when exposed to ultraviolet light, preventing absorption and bleed-through. For conventional inks, a formulation with high pigmentation allows for a thinner ink film. Pair this with a gentle drying system, like low-energy infrared (IR) dryers, to avoid overheating and damaging the delicate paper.

Ink management is a science, especially with porous, lightweight papers. The fibers in thin paper act like a sponge, wicking up traditional solvent-based inks. This causes two major problems: bleed-through, where the ink is visible on the reverse side, and show-through (or ghosting), where the printed image on one side is faintly visible from the other, even without bleeding. Both issues are unacceptable for premium products. Over the years, we’ve identified that the solution lies in a two-pronged approach: ink formulation and the drying method.

Choosing the Right Ink Formulation

The goal is to lay down a crisp, opaque layer of ink that sits on top of the paper fibers rather than sinking into them. This is where modern ink technology makes a huge difference.

- UV-Curing Inks: This is our top recommendation for high-quality work on thin stock. These inks are not solvent-based; they are a liquid polymer that hardens (cures) instantly when exposed to a UV light source. Because the curing is instantaneous, there is zero time for the ink to be absorbed by the paper. This completely eliminates bleed-through and results in incredibly sharp dots. LED-UV is an even better option as it generates less heat, reducing the risk of paper distortion.

- Oxidation-Drying Inks: For projects where UV printing isn’t an option, we turn to specific offset inks designed for uncoated, absorbent stocks. These inks have a higher pigment load, which means you can achieve the desired color density with a much thinner ink film. They are formulated to dry primarily through oxidation (reacting with the air) rather than absorption.

Implementing a Controlled Drying Process

The way you dry the ink is just as important as the ink itself. Aggressive, high-heat drying systems will bake the moisture out of the thin paper, causing it to shrink, curl, and become brittle.

| Drying Technology | Suitability for Thin Paper | Key Considerations |

|---|---|---|

| UV / LED-UV Curing | Excellent | The best option. It’s a "cold" process that cures ink instantly, preventing absorption and paper distortion. Requires a press with UV curing units. |

| Infrared (IR) Drying | Good | Effective for accelerating the oxidation of conventional inks. Must use low-energy settings to avoid overheating the paper. Often used in combination with air knives. |

| Hot Air Drying | Poor | Generally too harsh for ultra-thin paper. The high heat can easily cause severe wrinkling, shrinking, and brittleness. Avoid this method whenever possible. |

When using IR dryers, we always specify that the temperature should be kept to a minimum and that the paper web or sheet should be kept under gentle, consistent tension as it passes through the drying unit. This helps mitigate any potential for heat-induced distortion.

How Do You Ensure Perfect Print Registration and Finishing?

Your paper is feeding smoothly and the ink looks sharp, but now you notice another problem: the colors and text don’t align perfectly. This misregistration makes images look blurry and text hard to read. Furthermore, once printed, the delicate sheets are a nightmare to cut, fold, and bind without tearing or creasing. These finishing defects can ruin an otherwise perfect print job, turning a premium product into unsellable waste.

To ensure perfect registration, run the press at a slower speed and use automated registration systems that make micro-adjustments in real time. Maintain consistent web tension and a stable, climate-controlled environment. For finishing, use ultra-sharp blades for cutting, apply gentle scoring before folding to prevent fiber cracking, and choose binding methods like smyth-sewn or PUR that are strong yet flexible enough for delicate pages.

The final stages of printing and finishing are where precision becomes paramount. Any instability introduced in the earlier stages will manifest as registration errors. As a supplier, I know that even a 0.1mm shift can be noticeable to a discerning client. The same level of care is required after printing; cutting a stack of 40 gsm paper is very different from cutting 120 gsm cardstock. It requires specialized equipment and techniques to get a clean, professional finish.

Achieving Pinpoint Registration Accuracy

Registration is the precise alignment of different colors printed on top of each other. With ultra-thin paper, even the slightest change in tension or humidity can cause the paper to stretch or shrink minutely as it passes between printing units, throwing the registration off.

- Slower Press Speed: This is the simplest and most effective solution. Running the press at a reduced speed (e.g., 8,000 sheets per hour instead of 12,000) gives the paper more time to settle between color stations and allows automated registration systems more time to work.

- Automated Registration Control: Modern presses are equipped with camera-based systems that read registration marks on the fly. These systems automatically adjust the printing plates in real-time to compensate for any paper movement, ensuring the colors remain perfectly aligned throughout the entire run. We always prioritize working with print partners who have invested in this technology.

- Consistent Tension: As discussed in paper handling, maintaining absolutely consistent web tension from the reel to the delivery is critical. Any fluctuation will directly impact registration accuracy.

Mastering the Art of Finishing

Once the sheets are printed, the challenge isn’t over. The low tear resistance of thin paper makes it unforgiving in the finishing department.

| Finishing Process | Challenge with Thin Paper | Solution |

|---|---|---|

| Cutting | Blades can drag or tear the top sheets. The stack can compress unevenly. | Use a freshly sharpened, high-speed steel or carbide blade. Apply the lowest effective clamping pressure to secure the stack without marking it. |

| Folding | Paper can crack along the fold line, especially with ink coverage. | Score the paper before folding. A score creates a gentle indentation that guides the fold and prevents fibers from breaking. |

| Binding | Standard glues can cause pages to wrinkle. Stitches can tear through the paper. | For high-end books, smyth-sewn binding is ideal as it’s strong and allows the book to lay flat. PUR binding is a good alternative; it uses a strong, flexible glue that requires a thin application. |

For every project involving thin paper, we create a detailed finishing plan. This includes specifying the type of cutting blade, the precise pressure for scoring, and the exact binding method. It’s this attention to detail that ensures the final product is not only beautifully printed but also durable and functional.

Conclusion

Successfully printing on ultra-thin paper is a true test of a printer’s skill and technology. It requires a holistic approach that masters paper handling through precise tension and climate control, uses advanced ink and drying technologies like UV curing to prevent bleed-through, and maintains meticulous accuracy during the registration and finishing stages. It is a complex but achievable process.