Importing stationery but struggling with delays and missed deadlines? These hiccups can seriously hurt your bottom line. Proper timeline planning is the secret weapon you need.

Effective stationery production and import scheduling involves forecasting demand, detailed planning of resources (materials, labor), and creating a visual timeline of all key tasks and milestones.

For anyone in the import game, like my friend Michael over in Germany, getting your production timeline nailed down is super important. It’s not just about knowing when your Panoffices order will arrive; it’s about managing expectations, cash flow, and your own market commitments. Honestly, it’s a bit like planning a big trip – you absolutely need a good itinerary if you want to get anywhere smoothly! Let’s break down how to build a timeline that actually works, so you’re not just guessing.

How to make production planning and scheduling for stationery imports?

Confused about where to even begin with production planning? Without a clear roadmap, chaos and missed deadlines are pretty much guaranteed. Let’s simplify this whole process.

Make production planning by first forecasting demand, then assessing capacity. Follow with detailed scheduling of materials, labor, and machine time, factoring in potential disruptions for a realistic timeline.

Okay, let’s dive into this. When I’m helping a client plan their order for Panoffices goodies, the first thing we do is look at the end goal: When do you actually need this stationery on your shelves or at your client’s doorstep? Then, we work backward from there. It sounds simple, but it’s fundamental.

First up is Demand Forecasting. How many units of each Panoffices pen, notebook, or those cool desk organizers do you realistically need? This isn’t just a guess; it’s looking at past sales, upcoming promos, or seasonal trends. I always tell Michael, be realistic but also consider those peak buying seasons, like back-to-school.

Next, Supplier Lead Times. This is HUGE. We at Panoffices are pretty transparent about ours, but you need this info for every single component if you’re sourcing from multiple places. Think about raw materials for the factory – the paper, the ink, the little metal bits – and then the actual production time itself. These all add up.

Then, break it down into Key Stages:

- Order Confirmation & Deposit: Seriously, nothing kicks off without this.

- Material Sourcing: Does the factory have the specific paper, ink, or recycled plastics for our eco-friendly Panoffices line? If not, how long will it take to get them?

- Pre-Production Samples (PPS): These are essential for quality control. Michael never skips seeing and approving a PPS. Factor in time for making them and for your approval.

- Mass Production: This is the main event – the actual making of your lovely stationery.

- Quality Control (QC): Mid-production checks and final QC checks are vital. Add a little buffer time here, trust me.

- Packing & Labelling: Got custom packaging? That adds time.

- Booking Freight: Are you shipping by sea or air? This makes a big difference in timing.

- Customs & Transit: This can vary wildly depending on the countries involved.

And through all of this, Communication is King. Regular check-ins with your supplier (like us at Panoffices!) are absolutely vital. Don’t just place the order and then cross your fingers. Ask for updates, maybe even photos of the production. This helps you adjust your schedule if something unexpected – like a sudden port congestion or a typhoon delaying raw materials, which actually happened to me once with a big notebook order! – pops up. Clear, ongoing communication helps manage everyone’s expectations.What are the 5 steps of production planning for stationery?

Feeling a bit overwhelmed by all the moving parts in production planning? It can feel like you’re trying to climb a mountain. Let’s break it down into five manageable steps.

The 5 key steps are: 1. Demand Forecasting, 2. Resource Planning (materials, labor, machines), 3. Process Routing (sequence of operations), 4. Scheduling (assigning timelines), and 5. Monitoring & Control.

Alright, let’s get a bit more structured with this. I always think of it like baking a cake – you need a solid recipe and clear steps if you want it to turn out right! For stationery production, it’s pretty similar.

Step 1: Demand Forecasting. We touched on this, but it’s worth repeating. How much stationery do you need, and by when? This is the absolute foundation that everything else is built on. Michael, for example, usually looks at his past sales data and any upcoming marketing promotions his brand is planning.

Step 2: Resource Planning. This is where you figure out all the "ingredients" needed.

- Materials: What specific paper type, ink colors, plastics, or metals are required? And how much of each? Crucially, when do these materials need to be ordered by to arrive on time? For our Panoffices eco-range, sourcing certified recycled materials can sometimes have slightly longer lead times, so we factor that in.

- Labor: How many people will be needed on the production line? What specific skills do they need? And for how long will they be dedicated to your order?

- Machines: Which machines are needed for each part of the process (printing, cutting, binding, assembly)? What’s their output capacity? Is there one particular machine that might be a bottleneck if lots of jobs need it at once?

Step 3: Process Routing (or Sequencing). This is about defining the exact order things happen in. For a custom Panoffices planner, it might look like this: print inner pages -> collate sections -> stitch or glue bind -> apply the cover -> trim to final size -> conduct quality checks -> pack into boxes. Each of these steps takes a certain amount of time.

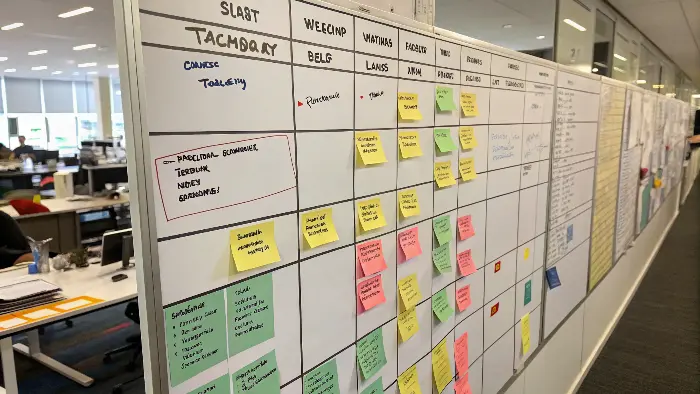

Step 4: Scheduling. Now you put actual dates and durations to all those tasks. "Printing will take 5 days, starting March 1st and finishing March 5th." Using a Gantt chart or even a detailed spreadsheet here is super helpful. And be realistic – don’t assume everything will go perfectly 100% of the time. I learned the hard way, years ago, to always add a little bit of buffer time for unexpected hiccups!

Step 5: Monitoring & Control. The plan is made, but your job isn’t done. Now you need to actively track progress. Are things running on schedule? If not, why? What adjustments are needed to get back on track? This is where that regular, open communication with your supplier is pure gold. You can’t just launch the plan and then hope for the best three months later. It’s an active, ongoing process.What is the detailed scheduling of production planning for stationery items?

Vague, fuzzy schedules are a one-way ticket to missed deadlines and a lot of stress. Need more precision, especially for complex stationery orders? Detailed scheduling is your answer.

Detailed scheduling in production planning assigns specific start and end times to each operation and workstation, optimizing resource use and identifying potential bottlenecks for efficient stationery manufacturing.

This is where we really get into the nitty-gritty, the almost minute-by-minute plan. It’s like zooming in on your overall project map to see every little turn. General planning might say, "Bookbinding will take 3 days." Detailed scheduling, on the other hand, would specify something like, "Binding Machine A will process 500 units of the Panoffices ‘Executive Journal X’ from 8 AM on Monday to 12 PM on Tuesday, then it will be switched over to Product Y, which will take 30 minutes for setup." See the difference?

It involves a few key things:

- Operation Breakdown: Every single tiny step in the manufacturing process is listed. For one of our Panoffices retractable pens, it could be: mold the barrel casing -> insert the ink refill mechanism -> print the client’s logo on the barrel -> assemble the clicker and cap -> individually pack.

- Time Allocation per Operation: How many minutes or hours are allocated for each of those tiny steps, often based on a standard batch size?

- Workstation Assignment: Which specific machine, or which particular team of workers, is responsible for each operation?

- Intelligent Sequencing: This is about arranging the order of jobs and operations to minimize wasted time, like the time it takes to change over a machine from one product to another. This is super critical in a busy factory environment like where Panoffices items are made. You don’t want an expensive printing press sitting idle for hours waiting for the next job.

- Capacity Loading and Balancing: This means making sure you’re not overloading one machine or one team while other resources are underutilized. It’s about smoothing out the workflow.

The tools for this can range from quite sophisticated Enterprise Resource Planning (ERP) software systems – which many larger factories use – to very detailed and cleverly designed spreadsheets. The absolute key here is visibility. If Michael, our German buyer, needs a mixed container with 10 different Panoffices SKUs, detailed scheduling is what ensures the factory can actually produce all of them in the right quantities and the right order to meet the container loading date. It helps spot potential clashes or problems before they happen. For example, if two high-priority products both need the same specialized embossing machine at the exact same time – uh oh, that’s a problem! Detailed scheduling would flag this conflict in advance, allowing the production manager to adjust. It’s all about making the absolute most of every minute and every piece of equipment.What is the production timeline for stationery, generally speaking?

Wondering how long stationery production really takes from start to finish? Guessing can be super risky and lead to broken promises. Let’s explore typical timelines to help set realistic expectations.

A general stationery production timeline can range from 4 to 12 weeks, or even more, depending on product complexity, level of customization, material availability, order quantity, and current factory workload.

Ah, the million-dollar question everyone asks! And the honest answer is… it really, really depends! I wish I could just give you a single, simple number, but "stationery" is such a broad category. A quick order for some standard, in-stock Panoffices pens is a completely different beast compared to, say, a fully custom-designed leather-bound journal with intricate debossing, special ribbon markers, and unique gift box packaging that Michael might spec out for a premium line.

Here are some of the major factors that heavily influence that timeline:

- Product Complexity: A simple, single-color printed notebook versus a multi-functional desktop organizer that might even have small electronic components like a clock or charger. The more parts and processes, the longer it takes.

- Level of Customization: Are we talking just adding a logo to an existing Panoffices product, or are we creating something from scratch? Custom colors (that unique Pantone shade Michael’s brand loves takes time for the factory to perfectly match and test), bespoke materials, completely new molds or dies, and elaborate custom packaging – all these things add time to the schedule.

- Order Quantity: A small trial order of a few hundred pieces versus a container load of tens of thousands of units. Interestingly, while larger orders take longer overall, the per-unit production time can sometimes be slightly faster due to efficiencies in longer machine runs and less frequent setup changes.

- Material Availability: This is a big one I always discuss upfront with my clients. Are all the necessary raw materials (paper, board, ink, plastics, metal fittings, adhesives) readily in stock at the factory, or do they need to be ordered in? Sourcing special types of paper, eco-friendly certified materials, or specific imported components can add weeks to the initial phase of the timeline.

- Factory’s Current Workload & Seasonality: Is it a typically busy period, like the run-up to the back-to-school season or major holidays? If the factory is already running at full capacity, your order will need to join the queue, which can extend lead times.

- Your Approval Stages: Don’t forget this part! How long do you or your team take to approve things like artwork proofs, pre-production samples, or color drawdowns? Delays on your side of the court will naturally push out the final delivery date.

So, with all that said, here are some very general ballparks (and I stress, these are rough!): - Simple, existing stock items, smaller quantity: Maybe 3-4 weeks for production.

- Moderately customized items, medium quantity: Could be in the 6-8 week range for production.

- Highly custom, completely new design, large quantity, special materials: You could be looking at 8-12+ weeks, just for the production phase.

And remember, this is typically just production time. You then need to add on the time for shipping (ocean freight from Asia to Europe or North America can easily be 4-6 weeks, plus port handling), customs clearance, and inland transit to your warehouse. So, for Michael in Germany to get a brand-new custom Panoffices stationery line, he’s probably wisely planning at least 3-4 months out, minimum, from the moment he signs off on the final design to when the goods actually land in his warehouse. The absolute key is to ask your supplier – like us at Panoffices – for their specific, detailed timeline for your specific order. Don’t ever assume!Conclusion

Planning stationery production and import timelines takes real effort. But clear forecasting, step-by-step scheduling, and open communication with suppliers like Panoffices ensure smoother sailing and on-time deliveries.