Choosing the wrong glue for your notebooks or planners can be a disaster. A weak spine leads to pages falling out, damaging your product’s quality and your brand’s reputation. To ensure your stationery is built to last, you need to understand the key differences between adhesives and select the one that guarantees durability and customer satisfaction.

For most high-quality, durable softcover publications, Polyurethane Reactive (PUR) adhesive is the best choice. Its bond is over 50% stronger than traditional Ethylene Vinyl Acetate (EVA) glue, offering superior flexibility that allows books to lay flat without the spine cracking. While EVA is a cost-effective option for short-term items, PUR’s resilience makes it the industry standard for premium notebooks, catalogs, and any product where longevity is critical. It performs exceptionally well across all paper types, including heavy and coated stocks.

Selecting the right adhesive goes far beyond just comparing strength. It’s a technical decision that impacts your product’s usability, its lifespan, and ultimately, how your customer perceives your brand’s quality. This choice involves considering the paper stock, the book’s thickness, and its intended use. To help you make a truly informed decision for your next production run, let’s break down the most common questions I get from product managers.

What kind of glue is used for perfect binding?

Are you looking to use perfect binding but feel unsure about which adhesive is the industry standard? Making a choice based on incomplete information can lead to weak spines and product failures. Let’s clarify the common glues used in this process so you can specify your requirements with confidence and avoid costly mistakes down the line.

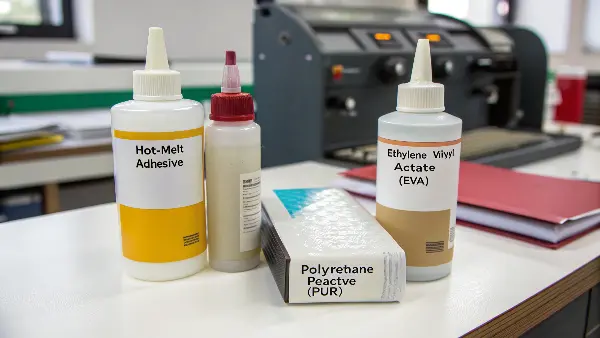

Perfect binding primarily uses hot-melt adhesives, with the two most dominant types being Ethylene Vinyl Acetate (EVA) and Polyurethane Reactive (PUR). EVA has been the traditional go-to for its rapid setting time and lower cost. However, PUR is now the preferred choice for premium products due to its exceptional strength, flexibility, and longevity. The best adhesive for a perfect-bound book ultimately depends on the project’s budget, the paper stock used, and how durable the final product needs to be.

Perfect binding is a method where individual pages are stacked into a block, and the spine edge is milled or roughed up. A strong, flexible hot-melt adhesive is then applied to the spine before the cover is wrapped around it. This process creates the clean, "perfect" edge you see on most softcover books. The type of glue used in this process is the single most important factor determining the final product’s quality and durability.

The Traditional Workhorse: EVA Glue

EVA is a thermoplastic, meaning it melts when heated and solidifies as it cools to create a physical bond. For decades, it has been the backbone of the publishing industry because it’s fast and economical. Machines can apply EVA, attach a cover, and trim the book in a single pass, making it ideal for high-volume, time-sensitive jobs like magazines or event brochures. However, its speed comes with trade-offs. The bond can become brittle over time, especially in cold environments, or soften in high heat. It also struggles to adhere properly to heavy, glossy, or coated paper stocks.

The Modern Powerhouse: PUR Glue

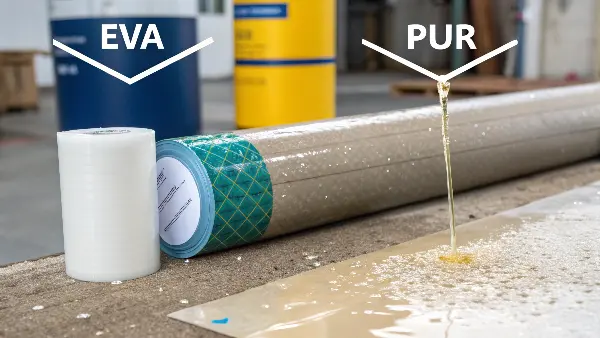

PUR is also a hot-melt adhesive, but its bonding process is fundamentally different. After being applied, PUR reacts with moisture in the paper and the atmosphere to undergo a chemical change. This curing process, which can take up to 24 hours to complete, forms a permanent and incredibly strong chemical bond. This bond is far more flexible and resilient than EVA’s physical bond, making PUR far superior for a wider range of applications.

| Feature | EVA (Ethylene Vinyl Acetate) | PUR (Polyurethane Reactive) |

|---|---|---|

| Bonding Process | Physical bond (melts and cools) | Chemical bond (reacts with moisture) |

| Strength | Good | Excellent (over 50% stronger) |

| Flexibility | Moderate (can crack over time) | High (allows for lay-flat designs) |

| Paper Compatibility | Best with uncoated, lighter stock | Excellent with all stocks, including coated & glossy |

| Temperature Resistance | Poor (can soften in heat, brittle in cold) | Excellent (stable in extreme temperatures) |

| Curing Time | Seconds | Up to 24 hours for full cure |

| Cost | Lower | Higher |

What is the difference between EVA and PUR?

You constantly hear suppliers and manufacturers talk about "EVA" and "PUR." But do you know the real differences and how they impact your final product? Choosing based on name alone, or simply on price, can be a costly mistake that compromises the quality you’ve worked so hard to design. Let’s break down the key distinctions so you can choose with certainty.

The main difference between EVA and PUR adhesives is their bonding chemistry and resulting performance. EVA is a thermoplastic that creates a physical bond by melting and solidifying, making it fast and affordable. In contrast, PUR is a reactive adhesive that forms a much stronger, permanent chemical bond by curing with moisture. This fundamental difference makes PUR significantly more durable, flexible, resistant to temperatures, and compatible with difficult paper stocks, whereas EVA is best for simpler, short-term applications.

To truly grasp the difference, think of EVA as a piece of tape—it creates a surface-level stick that holds things together. PUR, on the other hand, is like a weld—it fuses the materials together on a molecular level, creating a unified, unbreakable structure. This distinction has major implications for product performance.

Strength and Lay-Flat Durability

The number one reason product managers are switching to PUR is its sheer strength. As my insights noted, it’s over 50% stronger than EVA. This is confirmed by page-pull tests, where significantly more force is required to rip a page from a PUR-bound book. This strength translates into incredible durability. More importantly, PUR glue remains highly flexible after curing. This allows a PUR-bound notebook or textbook to lay almost completely flat on a desk without the spine cracking or pages coming loose. An EVA spine is more rigid and will often break if forced flat, compromising the book’s integrity from the first use.

Application and Material Compatibility

Here is where PUR really shines. EVA glue struggles to adhere to challenging surfaces. It doesn’t work well on heavily coated or glossy papers, as the ink and varnish prevent the glue from getting a good grip on the paper fibers. It’s also less effective on cross-grained paper. PUR overcomes all of these issues. Its chemical bonding process allows it to adhere securely to virtually any surface, including glossy catalogs, books with mixed paper types, and even synthetic substrates. I remember a client who insisted on using EVA for a line of high-end catalogs printed on heavy, coated stock. They were focused on a small cost saving. A few months later, they returned with complaints of pages falling out. We redid the entire job using PUR, and the problem was solved permanently. It’s a powerful lesson in how choosing the right material upfront protects your brand and saves money in the long run.

What is the difference between PUR and perfect binding?

Have you ever been in a conversation with a supplier who uses the terms "PUR binding" and "perfect binding" and felt a bit confused? It can sound like they are two competing options, leading to miscommunication about your project’s specifications. This lack of clarity can result in getting a product that doesn’t meet your quality standards. Let’s clear up this common point of confusion for good.

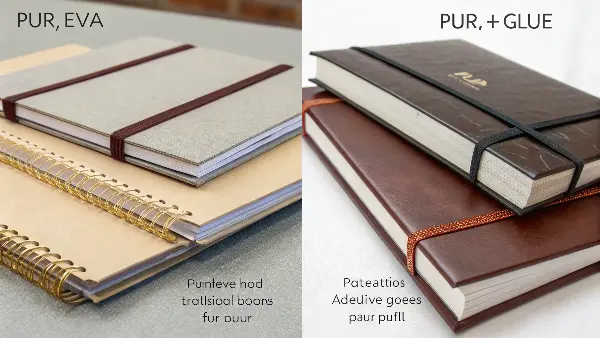

The key difference is that perfect binding is the name of the binding method, while PUR is a type of adhesive used within that method. Perfect binding is the process of gluing a book block to a soft cover. PUR (Polyurethane Reactive) is a high-performance glue that can be chosen for this process. Therefore, you don’t choose between perfect binding and PUR; you choose perfect binding with PUR glue for superior results.

Think of it like building a house. "Construction" is the method, and "concrete" is one of the materials you can use. You wouldn’t ask what the difference is between construction and concrete. Instead, you’d specify that you want your house constructed with reinforced concrete for maximum strength. The same logic applies here. "Perfect binding" is the "how," and "PUR glue" is the "what."

Perfect Binding: The Process

Regardless of the glue used, the perfect binding process remains the same. It’s a beautifully efficient method for creating the clean, flat spine common to softcover books, manuals, and catalogs. Here’s how it works:

- Collating: The printed pages are gathered and stacked in the correct order to form the book block.

- Milling the Spine: The spine edge of the book block is ground down, typically by a few millimeters. This roughs up the surface and exposes the paper fibers, creating a much better surface area for the adhesive to grip.

- Applying Glue: A hot-melt adhesive (either EVA or PUR) is applied directly to the milled spine.

- Attaching the Cover: The flat, scored cover is immediately wrapped around the book block and pressed firmly against the wet glue on the spine.

- Trimming: Once the glue has set enough to hold, the three open sides of the book a trimmed to create a perfectly neat, flush edge.

PUR: The Premium Material Choice

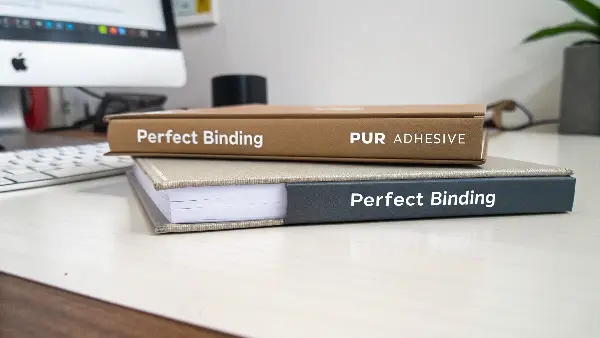

Within this process, the choice of adhesive is a critical decision. You can have a book that is "perfect bound with EVA" or one that is "perfect bound with PUR." When a supplier says "PUR binding," it’s industry shorthand for "perfect binding using PUR adhesive." They are emphasizing the superior quality of the material being used in the standard perfect binding process. Opting for PUR within this method is an upgrade that ensures the final product is stronger, lies flatter, and lasts significantly longer than its EVA counterpart.

So, what type of glue is best for book binding?

With all these technical details, you might still be wondering how to make the final call. How do you definitively decide which adhesive is the absolute best for your specific project? Choosing incorrectly can mean either overspending on a product that doesn’t need premium specs or, worse, compromising quality and disappointing your customers. Let’s create a clear framework for making the right choice.

For most high-quality stationery and publications, PUR is the best book binding glue. Its unmatched strength and flexibility make it ideal for any product intended to be durable, such as premium notebooks, thick catalogs, or reference manuals. EVA glue is a suitable, cost-effective alternative for disposable or short-term use items like magazines and event programs. Traditional glues are reserved for artisanal, casebound hardcover books and are less common in modern softcover production.

The best choice is always the one that aligns with your product’s purpose, quality level, and the user’s experience. You wouldn’t use the same materials for a disposable notepad as you would for a premium daily planner designed to last a full year. Here is a guide to help you specify the right adhesive for the job.

When to Choose PUR Glue

Specify PUR adhesive when quality and durability are non-negotiable. It is the best choice for:

- Premium Notebooks & Planners: Guarantees they withstand daily use.

- Thick Books & Catalogs: Essential for holding heavy book blocks together (typically over 48 pages).

- Coated & Glossy Paper: The only reliable option for binding slick, heavy, or cross-grained paper stocks.

- Lay-Flat Designs: The flexibility of PUR is required to allow books to open flat without spine damage.

- Long-Lasting Products: Ideal for reference manuals, textbooks, or any publication meant to be kept and used for years.

- Products Exposed to Temperature Extremes: The bond remains stable and won’t fail in hot or cold climates.

When to Choose EVA Glue

EVA remains a viable option when budget and speed are the primary drivers and longevity is less of a concern. Consider it for:

- Budget-Conscious Projects: It offers a significant cost saving per unit.

- Short-Lifespan Items: Perfect for event programs, thin magazines, or promotional booklets.

- Fast Turnaround Jobs: The instant setting time of EVA allows for quicker production cycles.

- Simple Projects: Works well for thin notepads with standard, uncoated paper.

| Project Type | Recommended Glue | Key Reason |

|---|---|---|

| Premium Daily Planner | PUR | Durability for daily use, lay-flat capability. |

| High-End Fashion Catalog | PUR | Adhesion to glossy/coated paper, premium feel. |

| Thick Company Annual Report | PUR | Strength to hold a heavy page count together securely. |

| Trade Show Magazine | EVA | Cost-effectiveness for a short-term use item. |

| Budget Notepads | EVA | Low cost and fast production for a simple product. |

Conclusion

Choosing the right adhesive is a critical decision in stationery production. While EVA offers a fast and economical solution for disposable items, PUR binding provides the unmatched strength and durability essential for premium products. Understanding these differences empowers you to create stationery that not only looks great but also stands the test of time, fully delivering on your brand’s quality promise.