Struggling to pick the right paper or cover for your book project? It’s a common hurdle. Choosing wrong means a final product that disappoints in look, feel, or durability.

The best materials depend on your book’s purpose: uncoated paper for text-heavy interiors, coated stocks for vibrant covers. Durability and aesthetics guide choices for binding, from simple paperbacks to robust hardcovers.

You know, it’s funny, before I really got into this business with Panoffices, I never gave paper a second thought. Paper was just… paper! But now, working with Michael, our product development whiz, I see how much thought goes into every single choice. He’s always balancing cost, feel, print quality, and durability for our clients who are sourcing stationery worldwide. He often says, "The material is the handshake of your product." And he’s absolutely right! That first touch tells you so much. So, let’s explore the options so you can make your book’s "handshake" a firm and impressive one. Trust me, understanding these basics can make a world of difference.

What are the stock options for printing a book’s pages and cover?

Overwhelmed by paper choices like "coated" or "uncoated," "GSM," or "lb"? This confusion can stall your project. You need clarity to select paper that makes your book shine.

Stock options include uncoated papers (great for text), and coated papers (gloss, silk, matte – ideal for images and covers). Weight (GSM/lb) also matters for feel and opacity.

When we’re starting any new project at Panoffices, especially if it’s a new journal or planner line for an international client, Michael always begins with the paper. It’s the foundation! He has this massive collection of paper samples – it’s quite something. The choices can seem endless, but they generally fall into a few main categories, and understanding these will make your life a whole lot easier. It’s not as scary as it looks, I promise!

Understanding Paper Basics: Coated vs. Uncoated and Weights

Let’s break down the main types of paper you’ll encounter for book printing, primarily for the inside pages and sometimes for simpler covers:

- Uncoated Paper:

- What it is: This is paper that hasn’t had a coating applied to its surface. Think of your standard office printer paper or the pages of most novels. It has a more natural, often slightly textured feel.

- Pros: It’s very absorbent, making it great for text-heavy books because ink sinks in nicely without glare. It’s often more economical. It also has a certain warmth and tactile quality that many people prefer for reading. I personally love the feel of uncoated paper for my own reading.

- Cons: Because it’s absorbent, images might not look as crisp or vibrant as on coated stock. Colors can appear a bit more muted.

- Common Uses: Novels, workbooks, journals, manuals, any book primarily focused on text.

- Coated Paper:

- What it is: This paper has a surface coating, typically made of clay or other polymers, that fills in the tiny pits and fibers of the paper. This creates a smoother, less porous surface.

- Finishes:

- Gloss: Very shiny, reflects a lot of light. Makes colors pop and images look sharp and vibrant. Think high-end magazines or photo books.

- Silk (or Satin): A smooth, elegant finish with a subtle sheen. It’s a nice middle-ground – colors are vibrant, but there’s less glare than gloss. Michael often recommends silk for premium Panoffices notebooks that need to showcase branding well.

- Matte: Smooth but with very little to no shine. It gives a more sophisticated, muted look. Good for reducing glare, but colors might not be quite as punchy as gloss or silk.

- Pros: Excellent for printing sharp, vibrant images and graphics. The ink sits on top of the coating rather than soaking in, leading to crisper details and richer colors.

- Cons: Can be more expensive. Glossy finishes can have glare issues under direct light. Fingerprints can also be more visible on some coated stocks.

- Paper Weight (GSM or lb):

- This refers to the thickness and heft of the paper. It’s usually measured in grams per square meter (GSM) or pounds (lb).

- Lighter weights (e.g., 80-100 GSM / 20-28 lb bond): Common for novel pages, office paper. More pages per inch, can be more economical.

- Medium weights (e.g., 115-150 GSM / 32-40 lb bond or 80 lb text): Good for brochures, higher-quality flyers, some booklet pages. Less show-through.

- Heavier weights (e.g., 170-300+ GSM / 65 lb cover to 110 lb cover and up): Used for booklet covers, paperback covers, business cards, postcards. Provides more rigidity and a premium feel.

Choosing the right stock is about matching the paper’s characteristics to your book’s content and desired quality. For instance, a children’s picture book would almost certainly use a coated stock to make the illustrations pop, while a dense academic textbook might stick with uncoated for readability.What is the best paper to print booklets on?

Trying to make a booklet that looks professional but unsure what paper makes sense? Choosing poorly leads to flimsy results or unnecessary expense, undermining your message.

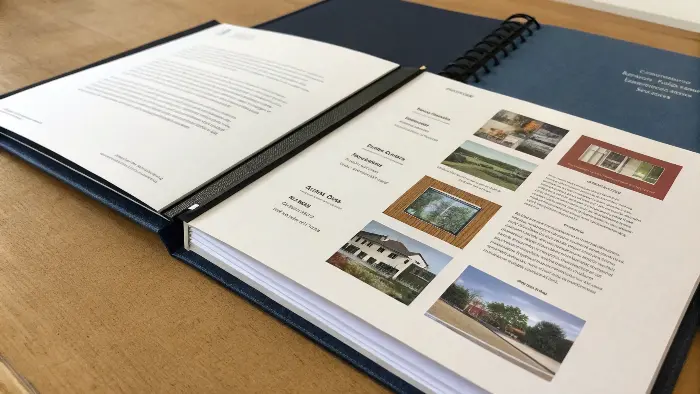

For booklet interiors, 80-100 GSM uncoated or silk coated paper is common. Covers often use 170-250 GSM silk or matte coated stock for durability and a quality feel.

Booklets are such a versatile format, aren’t they? We see requests at Panoffices for everything from simple event programs to more substantial product catalogs in booklet form. Michael often has to guide clients on paper choices here because the "best" paper really depends on the booklet’s purpose, page count, and how long it needs to last. A throwaway handout for a one-day event has different needs than a company profile booklet meant to impress potential investors.

Booklet Paper Considerations: Balancing Look, Feel, and Function

When we’re talking about booklets – usually saddle-stitched (stapled along the spine) or perhaps perfect bound if they’re thicker – here’s a breakdown of what generally works well:

- Interior Pages:

- Page Count Matters:

- Few Pages (e.g., 8-16 pages): You might get away with using the same paper stock for the cover and insides, especially if you choose a mid-weight paper like a 130-170 GSM silk or matte. This is called a "self-cover" booklet. It’s economical and can look quite neat.

- More Pages (e.g., 20-64+ pages): It’s usually better to use a lighter paper for the inside pages to prevent the booklet from becoming too bulky or stiff, which can make it hard to lay flat or for the staples to hold securely.

- Common Choices for Interiors:

- 80-120 GSM Uncoated: Great for text-heavy booklets, workbooks, or if you want a more natural, writable surface. It’s cost-effective.

- 90-150 GSM Silk or Matte Coated: A very popular choice if your booklet has a good mix of text and images. Silk gives a nice subtle sheen and good color reproduction without too much glare. Matte offers a more muted, sophisticated look. I often see our clients opt for a 115 GSM silk for internal pages of company brochures – it just feels a bit more substantial than standard printer paper.

- Gloss Coated (lighter weights like 130-150 GSM): Can be used if you want really vibrant, punchy images, but be mindful of glare.

- Page Count Matters:

- Cover Pages:

- Generally Heavier: The cover needs to protect the inside pages and give the booklet some substance.

- Common Choices for Covers:

- 170-250 GSM Silk or Matte Coated: This is a sweet spot for many booklets. It’s thick enough to feel durable but not so thick that it’s hard to fold or causes issues with saddle-stitching. Silk and matte are often preferred over gloss for covers as they tend to look more premium and are less prone to showing fingerprints.

- Up to 300-350 GSM for very robust covers or if perfect binding is used: For a really sturdy feel.

- Lamination: Often, booklet covers are laminated (a thin plastic film applied) for extra durability and to enhance the finish (e.g., matte, gloss, or soft-touch lamination). This is a great idea if the booklet will be handled a lot. Michael almost always recommends lamination for covers of frequently used items.

Key Tip: If your booklet has a dark or heavily inked cover, a matte or silk stock with a matte or soft-touch lamination can help prevent scuffing and fingerprint marks. Gloss lamination on a dark cover can be a fingerprint nightmare!

Ultimately, the "best" paper is a balance. For a simple, informational booklet, you might choose a 100 GSM uncoated for insides and a 170 GSM silk for the cover. For a high-end marketing piece, you might go for 150 GSM silk insides and a 250 GSM silk cover with soft-touch lamination. It’s all about matching the materials to the mission!What material is actually used for book binding covers?

Confused about what makes a sturdy book cover beyond just thick paper? This uncertainty can make choosing the right binding style and materials feel like a gamble.

Paperback covers use heavy card stock (coated, often laminated). Hardcover books use rigid binder’s board, wrapped in paper, book cloth (like buckram), or synthetic materials like faux leather.

This is where things get really interesting, especially when you move beyond simple booklets into the realm of "proper" books – paperbacks and hardcovers. The cover isn’t just about looking good; it’s a crucial structural component. I’ve seen firsthand at Panoffices how much a good cover contributes to the perceived value of, say, a premium planner or a corporate gift journal. Michael is meticulous about this.

Beyond Paper: Exploring Materials for Paperback and Hardcover Books

Let’s look at the common materials used:

- Paperback (Softcover) Books:

- Cover Stock: This is typically a heavy-weight paper card stock, much thicker than the interior pages.

- Weight: Often in the range of 250 GSM to 350 GSM (around 10pt to 14pt card).

- Coating: Usually coated on one side (C1S) or both sides (C2S). The coated side faces out for better print quality and durability. Silk or matte coatings are very common for a more sophisticated look, though gloss is also used.

- Lamination: Almost all commercially produced paperback covers are laminated (gloss, matte, or soft-touch). This adds significant durability, protects the ink from scuffing, prevents tearing, and can enhance the visual appeal. I rarely see a paperback these days without some form of lamination; it just makes sense.

- Printing: Covers are printed flat, then scored (creased) for the spine and folds before being glued to the book block (the collated inside pages).

- Cover Stock: This is typically a heavy-weight paper card stock, much thicker than the interior pages.

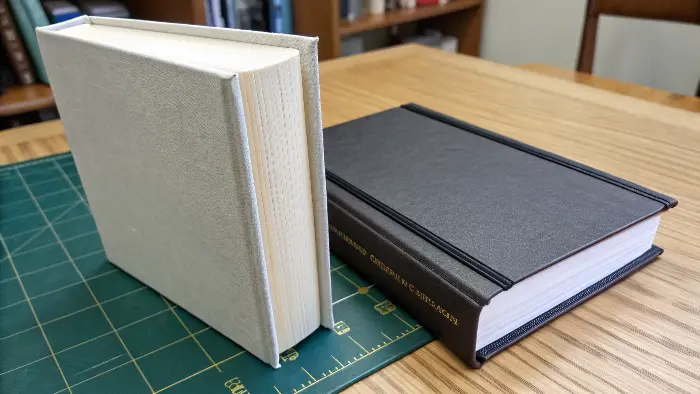

- Hardcover (Casebound) Books:

This is a whole different ball game! The cover (or "case") is made separately and then attached to the book block.- Binder’s Board (or Greyboard/Strawboard): This is the core material that gives hardcovers their rigidity. It’s a very dense, stiff board, typically 1.5mm to 3mm thick. The thicker the board, the more substantial the book feels.

- Cover Wrap Material: This is the material that is glued and wrapped around the binder’s board.

- Printed Paper: A common option, especially for fiction, trade books, and children’s books. A sheet of paper (often a 130-170 GSM coated stock for good print quality) is printed with the cover design, often laminated for protection, and then wrapped around the boards. Dust jackets are frequently used with paper-wrapped hardcovers.

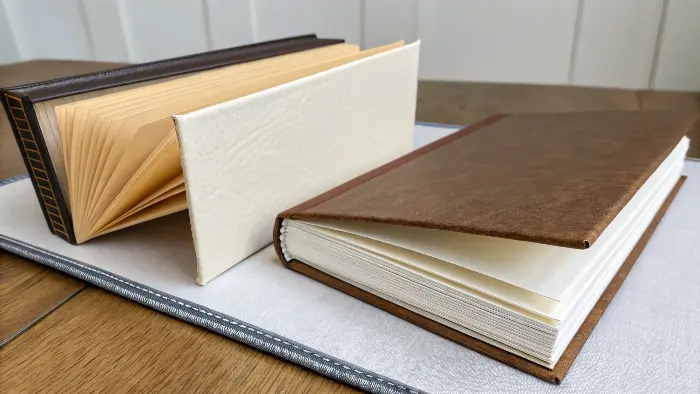

- Book Cloth: This is a traditional and very durable option.

- Buckram: A stiff, heavily sized cotton or linen cloth, often with an acrylic or pyroxylin coating, making it water-resistant, cleanable, and very durable. This is the go-to for library bindings and high-quality academic books. It has a distinctive texture.

- Linen or Cotton Cloths: Can be uncoated or lightly coated, offering a more natural, tactile feel. Often used for literary fiction, art books, or special editions.

- Faux Leather (PU Leather, Leatherette): Synthetic materials that mimic the look and sometimes the feel of real leather. Popular for journals, diaries, planners, and some types of books where a leather-like appearance is desired without the cost of real leather. We use a lot of high-quality PU leather for Panoffices’ executive planners.

- Real Leather: The most expensive option, usually reserved for very special editions, religious texts, or luxury bindings.

- Endpapers: These are the pages glued to the inside of the hardcover boards and also form the first and last leaves of the book block. They are crucial for the strength of the binding, especially at the hinge. They are often a heavier, uncoated, or colored paper stock.

The choice here dramatically affects the book’s durability, feel, and cost. A simple paperback is functional and economical. A cloth-wrapped or faux-leather hardcover signals quality and longevity.What is the best paper for bookbinding cover applications?

Want your book cover to be durable and look amazing but unsure which paper truly performs? Choosing a less-than-ideal paper can lead to premature wear, scuffs, or a cheap appearance.

For paperback covers, a 250-350 GSM coated (silk or matte) card stock, typically laminated, is best. For hardcovers using a paper wrap, a 130-170 GSM coated paper, also laminated, is excellent before wrapping onto boards.

This is a question Michael, our product development manager at Panoffices, tackles almost daily when designing new stationery lines or advising clients on custom book projects. The "best" paper for a cover really needs to balance print quality, durability, feel, and, of course, cost. It’s not just about thickness; it’s about the paper’s construction and how it interacts with printing and finishing processes.

Drilling Down: Optimal Paper Choices for Different Cover Types

Let’s get specific, because "cover" can mean different things:

- For Paperback Covers (Softcovers):

- Ideal Stock: You’re looking for a robust card stock.

- Weight: Typically 250 GSM to 350 GSM (grams per square meter), which translates to roughly 10pt to 14pt in thickness. Anything less might feel flimsy; much more can be hard to crease properly for the spine. I’ve found that a 300 GSM C1S (Coated One Side) stock often hits a sweet spot for a quality feel.

- Coating: Almost always coated – usually silk or matte. Silk offers a smooth finish with good color vibrancy without excessive shine. Matte provides an elegant, non-reflective surface. Gloss can be used, but it shows fingerprints more and can sometimes look a bit less "bookish" unless it’s for a very specific genre like graphic novels or some children’s books.

- Why Coated? The coating provides a smoother surface for printing, leading to sharper images and more vibrant colors. It also adds a degree of scuff resistance even before lamination.

- Crucial Addition: Lamination!

- This is non-negotiable for most quality paperbacks. A thin plastic film (gloss, matte, or soft-touch) is applied after printing.

- Benefits: Drastically increases durability (prevents tearing, protects against moisture and scuffs), enhances the printed colors, and improves the tactile feel (especially soft-touch lamination, which Michael loves for premium journals).

- Ideal Stock: You’re looking for a robust card stock.

- For Hardcover Books with Printed Paper Wraps (Case Making):

- Here, the paper isn’t the sole structural component of the cover (that’s the job of the binder’s board), but it’s the visible surface that carries the design.

- Ideal Stock: You don’t need super thick paper here because it needs to wrap smoothly around the boards.

- Weight: Typically 130 GSM to 170 GSM. A common choice is around 150 GSM.

- Coating: Again, coated paper (silk or matte) is preferred for print quality. The ink sits nicely on the surface, allowing for crisp text and vibrant images.

- Lamination: Highly recommended for the same reasons as paperback covers – durability and enhanced appearance. This printed and laminated sheet is then glued and wrapped around the stiff binder’s boards.

Things to Consider Beyond Basic Stock:

- Grain Direction: Paper has a grain direction. For covers, it’s important that the grain runs parallel to the spine for proper folding and to prevent cracking. Any good printer knows this, but it’s a detail that matters!

- Specialty Papers: For very high-end or artistic books, textured papers, colored papers, or papers with special inclusions can be used, though these often present printing challenges and are more expensive. These are less common for standard trade books but can be amazing for special editions. I once saw a project using a paper with visible fibers for a rustic-themed journal – it looked incredible.

Ultimately, for most book cover applications involving paper, a good quality coated stock in the appropriate weight, combined with lamination, will give you the best balance of appearance, durability, and printability.Conclusion

Choosing the right paper and cover materials is key. Uncoated for text, coated for vibrant covers, and robust boards for hardcovers ensure your book looks, feels, and lasts as intended.