Ever wondered why some books fall apart after a few reads, especially those from the library? It’s frustrating, right? This means lost knowledge, repeated purchases, and disappointment for readers.

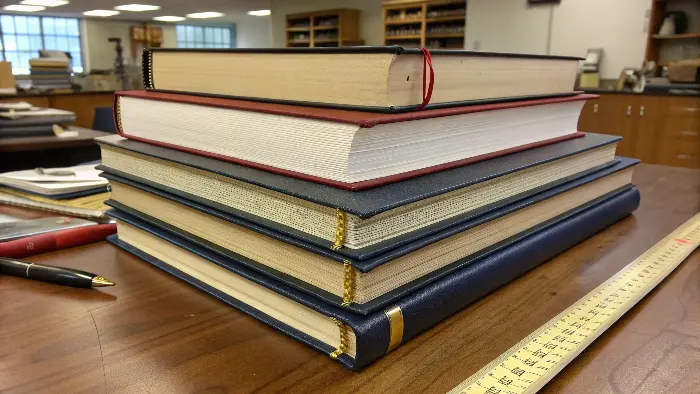

Library binding is a highly robust method creating books that endure frequent handling. Its higher cost reflects superior materials and construction, ensuring a significantly longer lifespan than standard hardcovers or paperbacks.

You’ve probably noticed that library books feel different, right? They’re built like tanks! I remember being a kid and just marveling at how these books could go through so many hands and still hold together. It’s not magic; it’s a specific type of construction. As someone who deals with Panoffices, producing all sorts of stationery and bound materials, I’ve come to really appreciate the engineering behind a truly durable book. So, let’s dive into what makes these bindings special and why they’re worth the investment, especially for institutions like libraries and schools. It’s a fascinating world, and understanding it can really change how you view the books on your shelf.

Do hardcover books actually last longer?

Buying books, expecting them to last, but then the spine cracks or pages fall out? It’s a common pain. This often leads to rebuying favorites, costing you more in the long run.

Yes, hardcover books typically last longer than paperbacks due to their rigid covers and often more robust page attachment. However, "library binding" represents the pinnacle of hardcover durability, a step beyond consumer hardcovers.

Okay, so when we talk about hardcover books, most people picture the ones you buy in a bookstore. And yes, generally, these are tougher than your average paperback. I’ve seen Michael, our product development manager at Panoffices, spec out some really nice hardcover journals, and they are designed for a good amount of use. He’s always focused on that balance of aesthetics and practicality for our clients.

- Standard Hardcovers vs. Paperbacks: The Basics

- Cover Construction: The most obvious difference is the cover. Paperbacks use flexible cardstock – think about your typical novel. It bends, it creases, and eventually, it can tear. Standard hardcovers, on the other hand, use thick "boards" – imagine very stiff, dense cardboard – which are then covered in printed paper (often with a laminate for protection), cloth, or a synthetic material like faux leather. This immediately gives the pages inside much better protection from bumps, spills, and general wear.

- Page Attachment Methods: Paperbacks most commonly use a method called "perfect binding." The edges of the collated pages are roughened, and then adhesive is applied to glue them directly to the spine of the cover. While this is cost-effective and works well for many books, the glue can become brittle over many years or with extreme temperature changes, leading to pages falling out. I’m sure we’ve all had an old paperback do that! Many standard hardcovers also use adhesive for page attachment (sometimes a stronger type like PUR glue, which is more flexible and durable). However, better-quality hardcovers will often feature "Smyth-sewn" signatures. This means the pages are first folded into sections (signatures), and then these signatures are sewn together with thread before being attached to the cover. This sewing makes a huge difference in how well the book lays open and how securely the pages are held.

- Where Standard Hardcovers Can Still Fall Short (for very intense use):

- Hinge Durability: The "hinge" – that flexible area where the cover bends open next to the spine – can still be a weak point on standard hardcovers if it’s not specifically reinforced. Repeated opening and closing can stress this area.

- Spine Integrity: While stronger than a paperback’s, the spine of a standard hardcover might not be designed for the hundreds, or even thousands, of openings a library book might endure without showing significant wear or becoming loose.

- Cover Material Wear & Tear: The material covering the boards, especially at the corners and edges, can scuff, fray, tear, or peel over time with heavy handling.

So, while your typical bookstore hardcover is definitely more durable than a paperback and a good investment for books you love, it’s not usually built for the kind of relentless, high-circulation handling a library book faces. Think about a popular children’s picture book at your local library – that thing might be checked out hundreds of times by eager little hands! My own kiddo has a few favorite hardcovers that are looking a bit rough around the edges, and they don’t get nearly the workout a library book does! This distinction is really key when we start talking about true long-term durability.Why are the prices of hardcover books generally more expensive than paperback versions?

Choosing between a pricey hardcover and a cheaper paperback for the same title? It’s a frequent dilemma. You want the story, but the format cost difference can be significant.

Hardcover books are pricier than paperbacks primarily because of more expensive materials (rigid boards, cloth/durable paper covers), more complex binding processes (case making, casing-in), and often higher-quality interior paper.

It’s a classic bookstore conundrum, isn’t it? You want the latest bestseller, and there it is in a sturdy hardcover for $28, and right next to it (or coming in a few months) will be the paperback for $16. Why the big gap? We’ve touched on some of this, but let’s really focus on the direct comparison between these two common formats. It’s something Michael, our product guy at Panoffices, considers all the time when developing new stationery lines – the materials and construction directly impact the perceived value and the price.

-

Hardcover vs. Paperback: A Closer Look at the Cost Factors

You’re essentially paying for a more robust and elaborately constructed product when you choose a hardcover.Feature Hardcover Paperback Cover Structure Rigid, thick boards (e.g., strawboard, greyboard, often 2-3mm thick) Flexible card stock (e.g., 10pt or 12pt C1S – Coated One Side) Cover Material Printed paper wrap (often with gloss or matte lamination), book cloth (linen, buckram), faux leather, etc. Printed card stock, possibly with a simple gloss or matte lamination Binding Process Case Making: The cover (case) is made separately. Casing-In: The sewn or glued book block is then adhered into this pre-made case. Signatures might be Smyth-sewn for better quality. Perfect Binding: Pages are collated, spine edge is milled/notched, and then hot-melt EVA or (better) PUR glue is applied to attach directly to the one-piece cover. Endpapers Almost always present. These are separate, often heavier, sheets of paper at the front and back that are glued to the inside of the cover boards, reinforcing the hinge. Typically, no separate endpapers. The first and last pages of the book block might be blank or part of the cover’s inside printing. Durability Focus Designed for greater longevity, better protection of pages, withstands more handling. Designed for affordability and portability; more prone to creasing, tearing, spine cracking with use. Shelf Appeal Often seen as more premium, substantial, and collectible. Dust jackets are common. More utilitarian, though cover design is still crucial for sales. Production Time & Complexity Longer and more steps involved (e.g., board cutting, case wrapping, building-in). Shorter and more streamlined process. - When Michael is developing a new line of, say, high-end journals for Panoffices, he knows that choosing a hardcover format immediately signals a higher quality and justifies a higher price point than a simple paperback notebook. The perceived value is intrinsically linked to the physical construction – it just feels more substantial.

You’re paying for: - Better Protection: That rigid cover isn’t just for show; it shields the pages from bends, dings, and spills far better than a flexible paperback cover.

- Longer Lifespan: They simply hold up better to repeated reading and being carried around. The spine is less likely to crack disastrously.

- Enhanced Aesthetics: Often, more care and expense are put into the design, printing, and finishing touches of a hardcover, like embossed titles or higher quality paper for the dust jacket.

- Collectibility: Many readers prefer hardcovers for books they intend to keep for a long time or display.

And if a standard hardcover is already this much more complex and costly than a paperback, you can start to imagine why a library-bound book, which takes all these hardcover qualities and significantly enhances them, would be even more of an investment. It’s all about layers of quality and durability.So, why are strongly bound books, especially library editions, so expensive?

Ever get sticker shock looking at the price of some bound books, especially robust hardcovers or special editions? It makes you wonder what goes into that price tag.

- When Michael is developing a new line of, say, high-end journals for Panoffices, he knows that choosing a hardcover format immediately signals a higher quality and justifies a higher price point than a simple paperback notebook. The perceived value is intrinsically linked to the physical construction – it just feels more substantial.

Bound books, especially hardcovers and super-durable library-bound editions, are expensive due to higher quality materials (dense boards, specialty cloth, strong adhesives, archival inks), more complex and labor-intensive manufacturing, and often smaller, specialized print runs.

So, why the hefty price tag on some bound books, particularly those built to last like library editions? It’s not just an arbitrary markup. As someone who’s frequently involved in sourcing and understanding manufacturing processes for Panoffices, even for our specialized stationery products, I can tell you that quality materials and intricate processes add up quickly. Now, imagine scaling that to a full book designed to withstand years, if not decades, of use!

- Key Cost Drivers for Premium Bound Books (especially robust hardcovers and library binding):

- Superior Materials – This is a biggie!

- Cover Boards: We’re not talking about flimsy cardboard. Library binding uses high-density, warp-resistant boards that provide a super-strong foundation. These cost significantly more than standard boards.

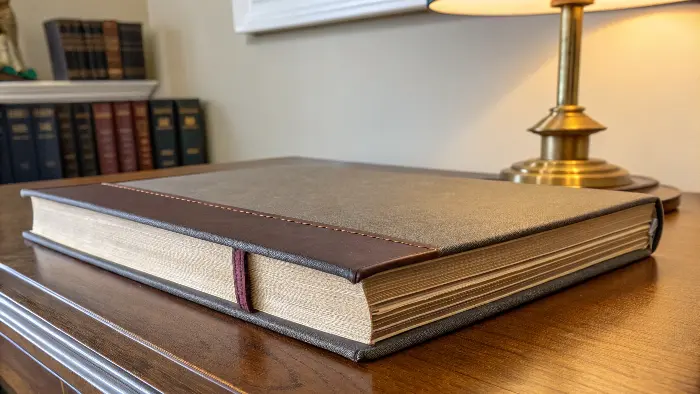

- Cover Material: The gold standard for library binding is often buckram. This is a very stiff, heavily sized cotton or linen cloth that’s incredibly durable, water-resistant, and cleanable. Other robust, coated cloths or specialized non-paper materials might also be used. These are miles apart in cost from the paper wraps on consumer hardcovers or the cardstock of paperbacks.

- Paper Quality (Interior): While not always dramatically different from a good trade hardcover, library editions will often use acid-free, archival-quality paper that resists yellowing and degradation over time.

- Adhesives & Thread: Library bindings use extremely strong, flexible, and long-lasting adhesives. If sewn (which is common), high-strength thread is used, and the sewing method itself (like oversewing or reinforced Smyth sewing) is chosen for maximum page security.

- Labor-Intensive & Complex Manufacturing Processes:

- Reinforced Endpapers: The endpapers in a library-bound book aren’t just pretty. They are often made of heavier paper stock and feature a cloth reinforcement (like cambric) at the hinge. This "joint" is critical for durability as it’s a major stress point.

- Sewing Method: Oversewing is a traditional library binding technique where small sections of pages (often individual leaves if the original book was perfect bound) are literally sewn through their sides, creating an almost indestructible text block. Modern library binding might also use very robust Smyth sewing with extra reinforcement. These methods are far more complex and time-consuming than simple gluing.

- Spine Reinforcement: The spine of the book block is often lined with extra material (like crash or flannel) for added strength and to help maintain its shape before the case (cover) is attached.

- Case Making & Casing-In: While similar to standard hardcovers, the precision and materials used in making the case and attaching the book block are often of a higher standard to ensure a tight, durable fit.

- Smaller, Specialized Print Runs:

- Mass-market paperbacks are printed in huge quantities, which significantly brings down the per-unit cost. Even trade hardcovers have larger runs than most library-bound editions. Library binding is often done by specialized binderies, sometimes even rebinding existing paperback or hardcover books to library specifications. These smaller, more bespoke runs mean that the setup costs for machinery and labor are spread over fewer units, increasing the cost of each book. I remember a special project for an archive where Panoffices facilitated the binding of just 50 unique historical document reproductions into library-style bindings – the per-unit cost was high, but the need for preservation was paramount.

- Quality Control & Standards: Library binding often adheres to specific industry standards (like those from the Library Binding Institute – LBI) that dictate materials and methods to ensure longevity. Meeting these standards adds to the cost.

So, when you see a $50, $60, or even $100+ library-bound book, a huge chunk of that cost is directly tied to the premium materials and the skilled, intensive labor required to make it a product that can genuinely last for generations of readers. It’s an investment in physical quality and endurance.Which book binding is the most expensive but also the most durable option available?

Need books that can truly withstand the test of time and countless readers without falling apart? Standard bindings often just don’t cut it for high-usage environments.

- Superior Materials – This is a biggie!

Library binding is unequivocally the most durable (and thus often the most expensive for its purpose) common bookbinding method. It’s specifically engineered for extreme longevity and frequent handling, far surpassing standard hardcover or paperback construction.

Alright, so we’ve established that general hardcovers are tougher than paperbacks, and that robust bindings cost more. But if you’re looking for the absolute king of durability, the heavyweight champion of the binding world specifically designed for high-circulation environments like schools and public libraries, then you’re talking about library binding. There’s really no contest for this purpose. It is the choice when a book simply has to last.

- What Makes Library Binding the Toughest and Often Priciest for its Niche?

It’s a combination of specific materials and construction techniques designed for one primary goal: to survive an incredible amount of use and abuse.- Oversewing or Heavily Reinforced Smyth Sewing: This is a cornerstone of traditional library binding.

- Oversewing: This method is incredibly strong. If a book is already in signatures, they might be separated, or if it’s a perfect-bound book, the spine is milled off. Then, small sections of pages (as few as 1/16th of an inch thick) are sewn together through the side of the pages, near the spine margin. These small, sewn sections are then combined and sewn to each other to form the text block. The result is a book block that is exceptionally resistant to pages pulling out. The downside is that books bound this way don’t always lay perfectly flat.

- Reinforced Smyth Sewing: If the book is made of signatures, a very robust version of Smyth sewing (sewing through the fold of each signature) is used, often with extra stitches, stronger thread, and techniques to link the sewing of one signature to the next very securely.

- Reinforced Endpapers with Cloth Hinges: The endpapers – those crucial pages that attach the book block to the cover – are not an afterthought. In library binding, they are made from heavy, durable paper stock and, critically, are reinforced with a strip of strong cloth (like cambric or muslin) along the hinge area. This reinforcement dramatically reduces the likelihood of the book block tearing away from the cover, which is a common failure point in lesser bindings. I’ve seen some old library books where the cover is battered, but those hinges are still holding strong!

- Stronger, Denser Cover Boards: The boards used to make the hard cover are typically much denser and more resistant to warping or breaking than those found in standard trade hardcovers.

- Ultra-Durable Cover Material: The covers are almost always covered in buckram (a very stiff, heavily coated cotton or linen library-grade cloth) or sometimes a high-strength, plastic-coated acrylic or pyroxylin-impregnated material. These materials are designed to be water-resistant, easily cleanable (important for library books!), and highly resistant to abrasion, scuffing, and tearing. They laugh in the face of sticky fingers and rough handling!

- Spine Reinforcement: The spine of the book block (before the cover is attached) is often lined with extra layers of material, such as crash (a coarse, open-weave fabric) and a strong paper lining. This helps the book retain its shape and adds further strength to the spine.

When Michael is sourcing suppliers for Panoffices, if a client – say, a university press or a special archive – needed something truly built for the ages or for extreme daily use, we’d look for specialized binderies that are experts in these LBI (Library Binding Institute) standards. It’s a different league entirely. You’re not just buying a book; you’re investing in a book that’s engineered to survive potentially hundreds, if not thousands, of circulations. The cost directly reflects this intensive labor, specialized machinery, and superior material selection. It’s like comparing a standard family car to a military-grade Humvee – both are vehicles, but one is designed and built for much, much tougher conditions and operational demands. This is why library binding, while an upfront investment, often proves more economical in the long run for high-use collections by drastically reducing repair and replacement costs.Conclusion

Library binding costs more upfront due to its robust materials and intensive construction. However, this investment ensures unparalleled durability, making books last significantly longer, especially in high-use environments.

- Oversewing or Heavily Reinforced Smyth Sewing: This is a cornerstone of traditional library binding.