Are you confused by terms like "India paper" and "Bible paper" when sourcing materials? Choosing the wrong lightweight paper for large books can lead to production issues like print-through, poor durability, and unhappy clients. This mistake can be costly, affecting your project’s quality and your brand’s reputation.

While often used interchangeably, "Bible paper" and "India paper" describe the same category of thin, strong, opaque paper. "India paper" is an older term from Oxford University Press for a specific lightweight paper, while "Bible paper" became the generic name due to its main use. For a publisher or stationery buyer today, the key is to focus on specific technical properties like GSM, opacity, and material composition rather than the name itself.

I remember when I first started in this business, these terms were a constant source of confusion. It took speaking with numerous paper mill engineers to really grasp the nuances. It seemed like everyone had a slightly different definition. Let’s break down what really matters when you’re choosing this type of specialty paper. Understanding these differences will help you make the right choice for your next project.

What Type of Paper is Actually Used for Bibles?

Choosing paper for a 1,000-page book feels incredibly daunting. You need it to be thin, but you can’t have the text showing through from the other side. This challenge makes you worry that you’ll pick a paper that is too thick, making the book heavy and bulky, or too transparent, making it unreadable.

Bibles primarily use a specialized type of uncoated, machine-finished paper known as lightweight offset paper. It’s engineered for high opacity and strength despite its low thickness. This is typically achieved by using quality fibers like cotton or linen mixed with chemical wood pulp, plus adding fillers like titanium dioxide. The goal is to create a durable, readable page that allows a large book to remain compact and lightweight.

When clients like Michael from Germany approach us for projects like large planners or reference books, the conversation always turns to finding this delicate balance. The specific "recipe" for this paper is where the magic happens. It’s not just one single type of paper, but a category defined by performance. The key is in the pulp and the additives.

Pulp and Fiber Composition

The foundation of any paper is its pulp. For Bible paper, manufacturers often use a blend of high-quality materials. You’ll find a mix of chemical wood pulp, which provides a good base, and other fibers like cotton or flax (linen). I’ve seen formulations that use up to 25-50% rag content (cotton or linen). These non-wood fibers are crucial because they have long, strong strands that create a very durable and tear-resistant sheet, even when it’s incredibly thin. This is a big reason why Bible pages don’t fall apart after years of use.

The Role of Fillers and Sizing

To solve the show-through problem, which we call "opacity" in the industry, mills add mineral fillers into the pulp slurry. The most effective of these is titanium dioxide (TiO2). It’s a very bright, white pigment that is excellent at scattering light. This prevents the ink from one side of the page from being visible on the other. Other fillers like calcium carbonate might also be used. Sizing agents are also added to control how the paper absorbs ink, ensuring crisp and clean text without feathering.

| Component | Role in Bible Paper Manufacturing | Common Materials Used |

|---|---|---|

| Pulp Fiber | Provides strength, durability, and tear resistance. | Chemical Wood Pulp, Cotton, Linen/Flax |

| Mineral Fillers | Increases opacity to prevent ghosting and improves brightness. | Titanium Dioxide (TiO2), Calcium Carbonate |

| Sizing Agents | Controls ink absorption for sharp, clean printing. | Starch, Synthetic Polymers |

| Finishing Process | Creates a smooth, uniform surface for better printability. | Machine finishing, calendering |

This combination of strong fibers and high-opacity fillers is what defines modern Bible paper and makes it suitable for its demanding purpose.

What is the Typical GSM of Bible Paper?

You’re designing a premium journal and want that delicate, lightweight feel, but you’re worried about performance. If the paper is too thin, will the ink bleed through? This uncertainty can stall a project, as choosing the wrong paper weight (GSM) could ruin the entire production run and disappoint your customers.

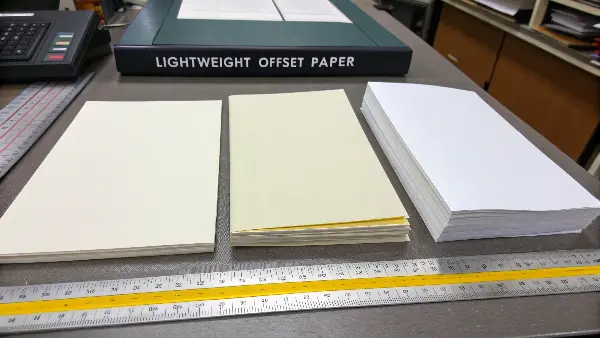

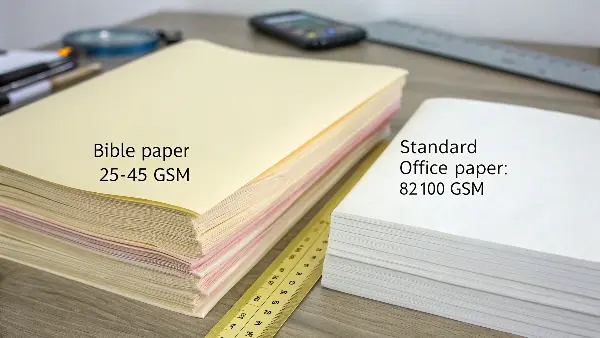

The GSM (Grams per Square Meter) for Bible paper is remarkably low, typically ranging from 25 to 45 GSM. Some specialty versions can even go as low as 20 GSM. This is significantly thinner than standard office paper, which is usually 80-100 GSM. This low weight is essential for keeping large-volume books, like Bibles or dictionaries, compact and manageable without sacrificing the paper’s strength or opacity.

This is one of the most critical specs I discuss with product developers. While a low GSM is desirable for weight, it introduces concerns about "ghosting" (seeing the print from the reverse side) and "bleed-through" (ink soaking through the page). Therefore, a low GSM must be paired with high opacity. It’s a technical balancing act that paper mills have perfected over centuries.

Balancing GSM and Opacity

The relationship between GSM and opacity is the core challenge in making Bible paper. Normally, a thicker, heavier paper (higher GSM) is more opaque. To achieve high opacity in a very low GSM sheet, manufacturers rely on the techniques we discussed earlier: a dense fiber matrix and specialized fillers.

A 30 GSM Bible paper can have a higher opacity rating than a standard 50 GSM wood-free uncoated paper. When I work with clients, I often provide samples to demonstrate this. You can hold a page up to the light and see just how well it obscures the text on the back. This hands-on test is often more convincing than any technical data sheet.

How GSM Impacts Product Design

The choice of GSM has a direct impact on the final product. Let’s look at how it affects a book:

| GSM Range | Total Page Count | Resulting Book Thickness | Ideal Use Case |

|---|---|---|---|

| 25-30 GSM | 1500 pages | Approx. 1.2 inches | Full-text Bibles, large reference works |

| 35-40 GSM | 1500 pages | Approx. 1.7 inches | Study Bibles, deluxe planners, legal books |

| 45-50 GSM | 1500 pages | Approx. 2.1 inches | High-end journals, literary collections |

| 80 GSM | 1500 pages | Approx. 3.5 inches | (Standard copy paper – too thick and heavy) |

As you can see, doubling the GSM from 30 to 60 would nearly double the thickness and weight of the book, making it impractical. This is why for any product with a high page count, getting the GSM right is the first and most important decision. It defines the physical presence and usability of the final product.

Is Bible Paper Typically Acid-Free?

You’re creating a product meant to last for years, maybe even generations. The thought that the paper might turn yellow and brittle over time is a major concern. If you choose the wrong paper, a beautiful heirloom Bible or a special-edition journal could degrade, reflecting poorly on your brand’s commitment to quality.

Yes, virtually all modern Bible paper is acid-free and often archival-quality. Manufacturers use alkaline papermaking processes, which result in a paper with a neutral or slightly alkaline pH (7.0 or higher). This prevents the internal chemical degradation that causes paper to become yellow and brittle over time. This longevity is crucial for books like Bibles, which are intended for long-term, frequent use.

The question of archival quality comes up frequently, especially for clients developing premium stationery or commemorative books. They want assurance that their product will stand the test of time. I always emphasize that for Bible paper, "acid-free" is a standard feature, not a premium add-on. It’s fundamental to the paper’s purpose. Let’s dive into why this is so important.

The Science of Acid-Free Paper

Historically, paper was made using methods that left acidic compounds, primarily from alum-rosin sizing agents, in the paper. These acids would break down the cellulose fibers over time, a process called acid hydrolysis. This is why very old books from the 19th and early 20th centuries often have fragile, yellowed pages.

Modern papermaking, especially for quality grades, shifted to an alkaline process.

-

Then (Acidic Process):

- Sizing: Alum-rosin sizing was used.

- pH: Below 7.0.

- Result: Paper contained residual acid, causing it to self-destruct over decades.

-

Now (Alkaline Process):

- Sizing: Synthetic sizing agents are used.

- pH: 7.0 or higher (alkaline).

- Result: Paper is chemically stable and resists aging, making it archival.

Alkaline paper is also often "buffered" with a mild alkaline substance like calcium carbonate. This buffer neutralizes acids that the paper might absorb from the environment, further extending its lifespan.

Why Archival Quality Matters for Bibles and Beyond

For a book like the Bible, which is read, studied, and passed down, longevity is paramount. Users expect the book to last a lifetime, and acid-free paper ensures this. But the application goes far beyond religious texts. Any document or book intended for long-term preservation benefits from acid-free paper. Think about legal documents, historical records, high-end art books, and journals meant for archiving personal memories.

When I specify paper for a project, I ensure it meets archival standards. This gives my clients, and in turn their customers, confidence that the product is a lasting investment. The term "acid-free" is a promise of permanence and quality.

Conclusion

In the end, whether you call it India paper or Bible paper, we are talking about the same thing: a thin, strong, and opaque paper. The key is not the name but the specifications. For your next project, focus on the GSM, opacity, fiber content, and its acid-free properties to ensure you get the performance you need for a lasting, high-quality product.