Are you a publisher looking to produce a Bible but feeling overwhelmed by the specific requirements? The intricate details of paper, binding, and special features can seem daunting, making it hard to know where to start. You need a guide to ensure you create a high-quality, durable, and beautiful edition that honors the sacred text within.

Navigating Bible production involves a series of critical choices about materials and manufacturing techniques. You’ll need to select lightweight yet opaque paper, choose a durable binding method like Smyth-sewn, and decide on cover materials and special features such as gilding or ribbon markers. The key is to partner with an experienced manufacturer who understands these unique requirements and can guide you through each step, from initial design to final delivery.

The process of creating a Bible is unlike producing any other book. It’s a blend of technical precision and artistic consideration, where every choice impacts the final product’s feel, longevity, and usability. From the whisper-thin pages to the sturdy cover, each component must be selected with care. This guide will walk you through the essential decisions you’ll need to make, breaking down the complexities into manageable steps. Let’s explore how you can turn your vision into a revered and lasting publication.

What Kind of Paper is Best for Printing a Bible?

Choosing the wrong paper can ruin a Bible printing project before it even begins. Thick paper results in a bulky, unwieldy book, while paper that’s too thin can suffer from ghosting, where text from the other side shows through. You need a solution that balances page count, readability, and durability without compromise.

The best paper for printing a Bible is typically a specialized, lightweight, and opaque paper often called "Bible paper" or "India paper." This paper has a low grammage (25-45 gsm) to accommodate a high page count without creating a bulky volume. Its high opacity is crucial to prevent show-through, ensuring the text on both sides of a page remains clear and legible. High-quality Bible paper is also acid-free for longevity and strong enough to withstand frequent page-turning.

When I first worked on a large-scale Bible project for a client in Europe, the paper choice was our biggest hurdle. They wanted a compact edition but with a readable font size, which meant we had over 1,500 pages to fit into a manageable book. This is where understanding the technical specifications of Bible paper becomes so important. It’s not just about being thin; it’s a careful balance of several factors.

Key Paper Characteristics to Consider

The goal is to find a paper that feels delicate but performs robustly. Here are the key attributes you need to discuss with your manufacturing partner:

- Grammage (Weight): Standard book paper is often 80-120 gsm (grams per square meter). Bible paper, however, is much lighter, usually falling between 25 gsm and 45 gsm. A lower grammage means more pages can fit into a thinner spine. For a standard pew Bible, 28-34 gsm is common. For a premium reference Bible with extensive notes, you might go slightly higher for better opacity.

- Opacity: This is perhaps the most critical factor. Opacity measures how much light passes through a sheet, determining how much the print on the reverse side is visible. It’s measured as a percentage. For Bible paper, you want an opacity of 80% or higher to ensure a comfortable reading experience. Our team always provides physical samples so clients like you can see and feel the difference.

- Durability and Longevity: Bibles are meant to be used for decades. The paper must be strong enough to resist tearing despite being thin. Look for paper made from high-quality pulp with long fibers. Also, ensure it is acid-free to prevent yellowing and degradation over time.

Here’s a simple comparison to help you visualize the options:

| Grammage (GSM) | Typical Use Case | Pros | Cons |

|---|---|---|---|

| 25-28 gsm | Compact, pocket, or travel Bibles | Very thin, lightweight, compact | Lower opacity, more delicate |

| 30-36 gsm | Standard pew or personal Bibles | Good balance of thinness & opacity | Standard choice, few cons |

| 38-45 gsm | Premium, study, or family Bibles | Excellent opacity, very durable | Results in a thicker, heavier book |

Choosing the right paper sets the foundation for a successful Bible. It directly impacts the reader’s experience and the testament’s physical lifespan. We always recommend starting with samples to truly understand how the paper’s weight and opacity will translate in the final printed product.

Which Binding Method Works Best for a Durable Bible?

You’re investing heavily in printing a beautiful Bible, but if the binding fails, the entire effort is wasted. A weak binding will lead to loose pages and a broken spine, especially for a book that is opened and referenced daily. You need a method that promises a lifetime of use, not one that will fall apart.

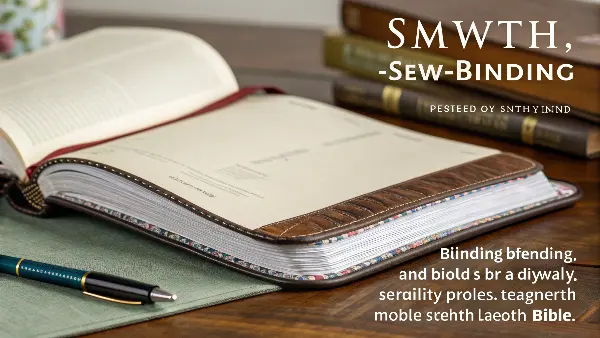

The most durable and widely recommended binding for Bibles is Smyth-sewn binding. In this method, the book’s pages are printed on large sheets, which are then folded into sections called signatures. These signatures are stitched together with thread before being glued to the cover spine. This technique allows the Bible to lie flat when open, reduces stress on the spine, and ensures no pages will ever fall out, making it the gold standard for long-lasting books.

Understanding the right binding method is crucial for a book intended for frequent, long-term use. While perfect binding (where pages are simply glued to the spine) is common and cost-effective for paperbacks, it’s not suitable for a Bible. The constant opening and closing will quickly crack the glue and cause pages to detach. We learned this early on when a potential client showed us a competitor’s Bible that was falling apart after just a year. This experience solidified our commitment to using only the most reliable methods for such important projects.

Comparing Common Binding Techniques

Let’s break down why Smyth-sewn is superior and look at other options you might encounter.

- Smyth-Sewn Binding: This is the premium choice. By sewing the signatures together, you create a text block that is incredibly strong and flexible. When you open a Smyth-sewn Bible, it lays flat on a table, which is ideal for study and referencing. It costs more and takes longer to produce, but its durability is unmatched. It is the only option we recommend for high-quality Bibles.

- Section-Sewn Binding: This is a general term that includes Smyth-sewn. The key principle is that pages are sewn in sections. It’s a hallmark of quality book production.

- Perfect Binding: In this process, the page edges are roughened and then glued directly to the cover spine. It’s fast and cheap, making it perfect for novels and magazines. However, the glue becomes brittle over time, and the book cannot lay flat without the spine creasing and eventually breaking.

- Case Binding: This refers more to the hard cover ("case") that a text block is attached to. A case-bound book can be either Smyth-sewn or perfect-bound. For a durable hardcover Bible, you must specify Smyth-sewn case binding.

Here’s a table to help you decide:

| Binding Method | Durability | Lays Flat? | Cost | Best For |

|---|---|---|---|---|

| Smyth-Sewn | Highest | Yes | High | All high-quality Bibles, reference books |

| Perfect Binding | Low | No | Low | Paperback novels, magazines, temporary books |

| Saddle Stitch | Low | Yes | Very Low | Booklets, brochures, thin materials |

| Spiral/Coil | Medium | Yes | Medium | Notebooks, workbooks, journals |

When discussing binding with your manufacturer, always use the term "Smyth-sewn" to ensure you are getting the quality you expect. It’s the structural backbone of a lasting Bible.

How Can You Choose the Right Cover Materials and Design for Your Bible?

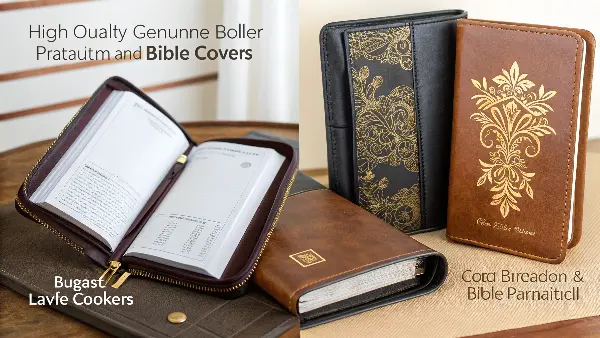

The cover is the first point of contact with your Bible. A cheap-feeling or poorly designed cover can make the entire book feel less valuable, regardless of the quality inside. You need to select materials that are not only aesthetically pleasing but also durable enough to protect the sacred text for years of handling and use.

Choosing the right cover involves balancing aesthetics, durability, and cost. Genuine leather offers a premium, traditional feel, while imitation leathers like PU or bonded leather provide a similar look at a lower cost. For design, focus on timeless typography and minimal, meaningful debossing or foil stamping. The cover should reflect the reverence of the text inside and be resilient enough for daily handling, making material choice paramount.

I remember working with Michael, a product manager from Germany, who was developing a new line of premium Bibles. He was very specific about the tactile experience. "It has to feel important in your hands," he said. We spent weeks going over material swatches, from full-grain goat leather to modern, soft-touch PU fabrics. This process highlighted that the cover isn’t just protection; it’s a key part of the user’s connection to the book. It sets the tone for worship, study, and reflection.

Exploring Cover Material Options

The material you choose will largely define the Bible’s quality, price point, and target audience. Here’s a breakdown of common choices:

- Genuine Leather: The top-tier option.

- Goatskin/Calfskin: Soft, flexible, and extremely durable. Often used for premium "heirloom" editions.

- Cowhide: Sturdy and classic, with a beautiful grain that ages well.

- Bonded Leather: This is made from leather scraps shredded and bonded together with polyurethane or latex. It’s an economical alternative to genuine leather but is far less durable and can peel or crack over time. We generally advise against it for a book meant to last.

- Imitation Leather (PU Leather): Polyurethane leather is a fantastic modern alternative. It’s vegan, available in a huge range of colors and textures, and very durable. High-quality PU can be soft, flexible, and difficult to distinguish from real leather. It’s a great choice for balancing quality and cost.

- Hardcover (Cloth or Paper): A classic and sturdy option, often seen in pew Bibles or gift editions. Linen or cotton cloth covers offer a warm, tactile feel and are very durable. Paper-over-board covers can feature full-color printed designs.

Design Elements for a Reverent Cover

The design should be respectful and timeless. Less is often more.

| Design Element | Description | Best For |

|---|---|---|

| Debossing/Embossing | Stamping a design into or out of the cover material. Creates a subtle, tactile effect. | Logos, titles, crosses, and simple decorative frames. |

| Foil Stamping | Applying metallic or colored foil (e.g., gold, silver) using a heated die. Adds an element of elegance. | Titles like "Holy Bible," crosses, and other significant symbols. |

| Spine Ribs/Hubs | Raised ridges on the spine, a traditional feature that adds structural and visual appeal to leather Bibles. | Classic, premium, and heirloom editions. |

When you combine a quality material like Smyth-sewn binding with a thoughtful cover—perhaps a soft PU leather with simple gold foil stamping—you create a product that is both beautiful and built to endure.

What Special Features Can Make Your Bible Stand Out?

In a market with countless Bible editions, simply printing the text isn’t enough. Publishers need to add features that enhance the reading experience and provide tangible value. Without these thoughtful details, your edition might get lost on the shelf, seen as just another basic version with no compelling reason for purchase.

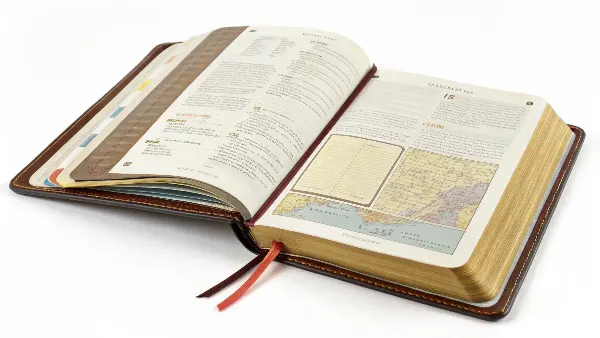

To make your Bible stand out, incorporate functional and aesthetic features like gilded or art-gilded page edges, multiple ribbon markers for easy navigation, and thumb indexing for quick reference to different books. Other valuable additions include study notes, concordances, full-color maps, and a presentation page for gifting. These details transform a standard Bible into a premium, user-friendly tool for study and worship.

We once had a client who wanted to create a special confirmation gift Bible. They were competing with many other publishers, so we focused on features that would appeal to a younger audience receiving the book as a milestone gift. We suggested a soft, durable cover in contemporary colors, two ribbon markers (one for the Old Testament and one for the New), and art-gilding on the page edges that revealed a subtle design when the pages were fanned. These small touches made all the difference and turned their product into a bestseller.

Elevating Your Bible with Added Value

Special features can be broken down into two categories: aesthetic enhancements and functional tools. A successful Bible often includes a mix of both.

Aesthetic Enhancements

These features are about beauty and creating a premium feel.

- Gilded Edges: The application of gold, silver, or other metallic foil to the edges of the text block. It looks beautiful and also helps protect the thin pages from moisture and dust.

- Art Gilding: Also known as Scofield gilding, this is a premium feature where a colored design or lettering is printed on the page edges. It is often hidden by the gold or silver gilding and is only revealed when the pages are fanned.

- Presentation and Family Record Pages: Including beautifully designed pages at the front for gift inscriptions or recording family history (births, marriages) makes the Bible a cherished heirloom.

Functional Tools

These features are about improving usurpability and making study easier.

| Feature | Description | Benefit to the Reader |

|---|---|---|

| Ribbon Markers | One or more silk ribbons bound into the spine to mark pages. | Allows readers to quickly return to multiple passages without damaging pages with dog-ears. |

| Thumb Indexing | Die-cut tabs on the page edges labeled with the books of the Bible. | Helps users find specific books quickly, which is especially useful for new readers or pastors. |

| Concordance | An alphabetical index of principal words used in the text, showing where they can be found. | An essential tool for in-depth study, allowing readers to trace themes and ideas. |

| Full-Color Maps | Maps of the ancient world relevant to the biblical narrative, typically included in the back. | Provides geographical context, making the stories and journeys more tangible. |

| Study Notes/References | Footnotes or side-column notes that explain complex passages, provide historical context, or cross-reference other verses. | Transforms the Bible from a simple text into a comprehensive study resource. |

By carefully selecting a few of these features, you can significantly increase the perceived and actual value of your Bible, creating a product that is not only beautiful but also an indispensable aid to the reader.

How Do You Select the Right Manufacturing Partner for Bible Production?

Choosing a manufacturer for a project as specialized as a Bible is a critical decision. A general-purpose printer may not understand the nuances of thin paper, the importance of lay-flat binding, or the precision required for features like gilding. Partnering with the wrong supplier can lead to costly errors, poor quality, and a final product that fails to meet expectations.

To select the right manufacturing partner, look for a supplier with demonstrable experience in Bible printing. Ask for physical samples of their previous work to assess paper quality, binding strength, and cover finishing. Ensure they have a deep understanding of specialized materials like India paper and techniques like Smyth-sewn binding. Finally, choose a partner who communicates clearly and provides transparent guidance throughout the entire production process.

As a B2B supplier, we know that trust is built on expertise and communication. I recall a new client who came to us after a disastrous experience with another factory. Their previous supplier had used the wrong glue for the binding, and the covers were already peeling on the pre-production samples. The client had lost time and money. This reinforced for us that our job isn’t just to manufacture; it’s to be an expert partner. We guide our clients, like Michael from Germany, through every technical decision to prevent these kinds of problems and ensure the final product is perfect.

Key Questions to Ask a Potential Manufacturer

When you’re vetting potential partners, don’t be afraid to ask detailed questions. Their answers will reveal their level of experience and capability.

- "Can you show me samples of Bibles you have produced?"

This is non-negotiable. You need to see and feel the quality of their work. Pay attention to the details: Does the book lay flat? Is the foil stamping crisp? Is the page opacity sufficient? - "What types of Bible paper do you have in stock or can you source?"

An experienced manufacturer will be able to discuss gsm, opacity, and pulp composition. They should be able to provide you with paper samples to test. - "Do you offer Smyth-sewn binding in-house?"

Confirm they use this specific method for Bibles. Some manufacturers may outsource this, which can add cost and complexity. In-house capability is often a sign of a specialized printer. - "What cover materials and finishing options (debossing, foil, etc.) do you recommend?"

Look for a partner who can offer a wide range of materials and provide expert advice on what works best for your target market and budget. - "What is your quality control process for a complex project like this?"

A good manufacturer will have a multi-step quality control process, from checking page signatures before binding to inspecting cover application and special features before packing.

Vetting Checklist for Your Ideal Partner

| Area of Evaluation | What to Look For | Why It’s Important |

|---|---|---|

| Specialized Experience | A portfolio filled with high-quality Bible or religious text projects. | They understand the unique challenges and won’t be learning on your project. |

| Technical Knowledge | Fluent in terms like "Smyth-sewn," "India paper," "gilding," and "debossing." | Ensures clear communication and that technical specifications will be met accurately. |

| Communication & Support | A dedicated contact person who is responsive, transparent, and can guide you through decisions. | A complex project requires a partnership, not just a transaction. |

| Quality & Samples | Willingness to provide a variety of physical material and final product samples. | You must approve the quality with your own hands before committing to a full production run. |

Choosing your manufacturing partner is the final and most crucial step. A great partner acts as an extension of your team, bringing the expertise and care needed to produce a Bible that will be treasured for generations.

Conclusion

Creating a Bible is a journey that requires careful attention to detail, from the delicate paper and strong binding to the beautiful cover and helpful features. By making informed choices at each stage and selecting an experienced manufacturing partner, you can confidently produce a high-quality, lasting edition that truly honors the sacred text it contains.