Struggling to find notebooks that truly reflect your brand? Off-the-shelf options feel generic. You need something unique to impress your customers and stand out.

Sourcing perfect custom notebooks involves defining specifications (size, paper, cover, binding), finding a reliable manufacturer like Panoffices, clear communication, and quality checks throughout the process.

You know, Michael, our buyer from Germany, often talks about this. He’s not just looking for a notebook; he’s looking for the notebook that his customers will love and that perfectly represents his brand’s quality. It’s a big deal! And honestly, getting it right can seem daunting, but it doesn’t have to be. So, let’s break down what really matters when you’re diving into the world of custom notebook manufacturing. It’s kinda like being a chef; you need the right ingredients and the right recipe to make a masterpiece!

What Key Customization Options Should You Prioritize for Notebooks?

Overwhelmed by choices for custom notebooks? So many details, so little time! You need to focus on what truly makes a difference for your brand.

Prioritize cover material and design, paper type and ruling, binding method, and branding elements (logo, colors). These significantly impact the notebook’s look, feel, and functionality.

When Michael sends us a brief for a new Panoffices notebook line, he’s super specific about these things – and for good reason! These are the building blocks. It’s not just about making a notebook; it’s about making your notebook. I remember when we first started working with him, he sent us this incredibly detailed mood board. It really helped us get inside his head!

Cover Considerations – The First Hello!

The cover is the first thing people see and touch. It’s gotta make an impact!

- Material: What vibe are you going for?

- Hardcover (Case Bound): Super durable, feels premium. Think PU leather, linen, or printed art paper wraps. Michael loves a good PU leather for his executive line.

- Softcover: More flexible, can be cardstock, Kraft paper, or even flexible plastic. Great for everyday use. We did a fantastic run of softcover Kraft notebooks with a minimalist white foil stamp for an eco-conscious brand – they looked amazing.

- Specialty Materials: Cork, recycled leather, fabric… the sky’s the limit if you want something really unique.

- Printing & Finishing: This is where your brand’s personality really pops!

- Offset Printing: For full-color designs, patterns, or photographs.

- Foil Stamping: Adds a touch of luxury with metallic or colored foils. Gold, silver, rose gold are always popular.

- Embossing/Debossing: Creates a raised or indented design. A blind deboss (no ink) is so classy!

- Spot UV: Adds a glossy, raised coating to specific areas.

Paper Particulars – The Heart of the Notebook

The writing experience is crucial. Don’t skimp here!

- Weight (GSM – Grams per Square Meter):

- 70-80gsm: Standard for everyday notebooks, good for general writing.

- 90-100gsm: A bit thicker, less show-through, feels more premium. Michael often specs this for journals.

- 120gsm+: Lovely for fountain pens or sketching, very little bleed-through.

- Type & Ruling:

- Lined: The classic. Think about line height (6mm, 7mm, 8mm).

- Grid (Graph): Perfect for designers, engineers, or bullet journaling.

- Dotted: Super popular for bullet journals, offers guidance without being intrusive.

- Blank: For sketching and free-form notes.

- Custom: We’ve printed custom weekly planner layouts, project logs, all sorts!

- Color: White is standard, but cream/ivory can feel softer and more high-end. Recycled papers often have a natural, slightly off-white look.

Binding Styles – Holding It All Together

The binding affects usability and durability.

- Spiral/Wire-O: Lays completely flat, pages turn easily. Great for students and note-takers who need to write across the full spread.

- Saddle-Stitched: Pages are folded and stapled through the spine. Economical for thinner notebooks (usually up to 64-80 pages).

- Perfect Bound: Like a paperback book, pages are glued to the spine. Looks sleek and professional.

- Case Bound (Sewn): Signatures of pages are sewn together, then glued into a hardcover. The most durable and premium option. This is Michael’s top choice for his signature journal collections.

- Singer Sewn: A visible stitch down the spine, often in a contrasting color. Adds a handcrafted, boutique feel.

Branding Touches – Those Little Extras

These details elevate a good notebook to a great one.

- Logo Placement: Cover (front, back), spine, even subtly on each page.

- Custom Endpapers: The pages glued to the inside of the covers. A great spot for a brand pattern, color, or message.

- Ribbon Marker(s): In your brand color(s).

- Elastic Closure Band: Keeps the notebook tidy.

- Pen Loop: Super practical!

- Belly Band or Custom Sleeve: Adds retail appeal and space for more branding.

Seriously, thinking through these options methodically is key. It’s like building your dream notebook from the ground up. Don’t be afraid to ask your manufacturer (like us at Panoffices!) for samples of different materials and finishes. It makes all the difference to see and feel them yourself.How Can You Ensure Quality Control When Sourcing Custom Notebooks Overseas?

Worried about inconsistent quality from overseas suppliers? Bad products damage your brand. You need reliable ways to ensure every notebook meets your standards.

Ensure quality by requesting pre-production samples, clearly defining specifications, establishing inspection protocols (during and post-production), and maintaining open communication with your manufacturer.

This is a BIG one for Michael, and frankly, it’s a cornerstone of how we operate at Panoffices. Quality isn’t just a buzzword; it’s the foundation of a good product and a good partnership. Sourcing from overseas can offer amazing capabilities and cost-effectiveness, but you absolutely must have robust quality control measures in place. It’s like, you wouldn’t buy a car without test-driving it, right? Same principle.

Pre-Production Samples (PPS) are Your Best Friend!

I cannot stress this enough: Never. Skip. The. PPS. This is your physical, tangible proof of what the final product will look like. It’s your chance to:

- Verify Materials: Is the cover the exact PU leather you chose? Is the paper the correct 100gsm cream stock? Feel it, test it.

- Check Print Quality: Are the colors accurate to your Pantone specifications? Is the logo sharp and correctly placed? Is the foil stamping clean?

- Assess Construction: Is the binding strong and neat? Are the pages aligned properly? Does the elastic closure have good tension?

- Test Functionality: If it has a pen loop, does a standard pen fit? Does the ribbon marker feel secure?

I remember one time, we were working on a new journal for Michael. The digital proof looked perfect. But when the PPS arrived, the debossing on the cover wasn’t quite as deep as he’d envisioned. It was a subtle thing, but important for the tactile feel he wanted. Because we had that PPS, we were able to adjust the die before mass production. Imagine if 2,000 units had been made with that slightly-off deboss! Disaster averted. So, budget time for PPS review and potential revisions. It’s worth its weight in gold.Crystal Clear Specifications – Leave No Room for Guesswork

The more detailed your tech pack or specification sheet, the better. Think of it as the architectural blueprint for your notebook. It should include:

- Dimensions: Overall size, page size.

- Page Count: Be precise.

- Paper Details: GSM, type (lined, grid, dot, blank), ruling color, line spacing, margin widths.

- Cover Details: Material, color (Pantone refs!), thickness, print method (offset, foil, emboss), artwork files.

- Binding Type: Specifics like coil diameter if Wire-O, or thread color if Singer sewn.

- Extras: Ribbon color and width, elastic color and width, pen loop material and placement.

- Packaging: Individual shrink-wrap, belly band details, master carton requirements.

We work with our clients to create these detailed spec sheets and get sign-offs before anything goes into production. It protects everyone.Inspection Protocols – Eyes on the Prize

- During Production (DUPRO) Checks: For larger or more complex orders, having someone check the products as they are coming off the line can catch systemic issues early.

- Final Random Inspection (FRI): This is standard. Before the goods are shipped, a trained inspector will check a random sample of the finished products against your approved PPS and spec sheet. They use AQL (Acceptable Quality Limits) standards.

- Third-Party Inspection Agencies: For an extra layer of impartiality, especially when working with a new supplier, you can hire companies like SGS, Intertek, or QIMA. Michael sometimes uses these for very high-value orders.

Communication is Key 🔑

Maintain an open and frequent line of communication with your manufacturer. Ask for production updates, photos, or even short videos. At Panoffices, we try to be proactive with this. If we foresee a potential issue, we’ll flag it immediately. It’s about building trust and working as a team. Finding a manufacturing partner who is transparent and responsive is just as important as the physical product.

What Are the Typical Lead Times and MOQs for Custom Notebook Orders?

Unsure about production timelines and minimum order quantities? Miscalculations can mess up your launch. You need realistic expectations for planning effectively.

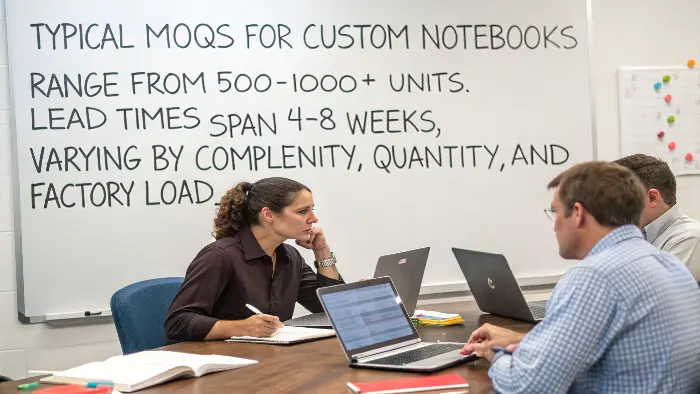

Typical MOQs for custom notebooks can range from 500-1000+ units. Lead times, including sampling and mass production, often span 4-8 weeks, varying by complexity, quantity, and factory load.

"So, how many do I need to order, and when will I get them?" This is probably one of the first questions Michael asks when we’re kicking off a new Panoffices project! And it’s super important for his planning, especially with seasonal collections or specific launch dates. Let’s be real, nobody likes surprises when it comes to deadlines and minimums.

Minimum Order Quantities (MOQs) – Why So Many?

Manufacturers have MOQs because there are fixed costs involved in setting up a custom production run. Think about it:

- Machine Setup: Each machine (printing press, binding machine, die-cutter) needs to be configured for your specific job. This takes time and labor.

- Material Sourcing: Suppliers of paper, cover materials, foils, etc., often have their own MOQs. We can’t just buy 3.5 sheets of that special Italian PU leather Michael loves; we have to buy a roll.

- Printing Plates/Dies: For offset printing, new plates are made. For foil stamping or embossing, custom metal dies are created. These are one-off costs per design.

So, the MOQ helps to spread these setup costs over a reasonable number of units, making the per-piece price viable. - Typical Range: For us at Panoffices, a common MOQ for a fairly customized A5 notebook might start around 500 to 1,000 pieces.

- Factors Affecting MOQ:

- Complexity: A simple, one-color print, saddle-stitched notebook might have a lower MOQ than a case-bound, multi-process, foil-stamped, embossed journal with a custom ribbon.

- Materials: If you choose a very unique or imported material, the MOQ might be dictated by the material supplier’s minimum.

- Supplier Flexibility: Sometimes, for a good long-term client like Michael, or if we can group your order with similar materials, there might be a little wiggle room. But it’s always best to ask upfront!

Lead Times – Good Things Take Time! ⏳

Patience is a virtue in custom manufacturing! Here’s a general breakdown:

- Quotation & Detail Confirmation (1-2 weeks): This includes back-and-forth on specs, pricing, and artwork.

- Pre-Production Sample (PPS) (1-3 weeks): Creating and shipping the sample for your approval. This can take longer if revisions are needed. Michael is very thorough here, which is good!

- Mass Production (3-6 weeks, sometimes more): This is the big one. The actual making of your notebooks. It depends heavily on:

- Quantity: Obviously, 10,000 notebooks take longer than 1,000.

- Complexity: A notebook requiring multiple print processes (e.g., offset print + foil + emboss), special hand-assembly (like tip-ins or belly bands), will take longer.

- Factory Schedule: Is it peak season (e.g., pre-Christmas, back-to-school)? Factories can get very busy.

- Material Availability: Are all components readily available, or do some need to be ordered in?

- Quality Control & Packing (3-7 days): Final inspections and getting everything boxed up according to your specs.

- Shipping (Varies HUGELY):

- Sea Freight: Most common for bulk, but slow. To Europe or North America from Asia, this can be 4-6 weeks (or more!).

- Air Freight: Fast (days), but much more expensive. Usually for urgent top-ups or samples.

- Rail/Truck: Depending on geography.

So, realistically, from the moment you sign off on the order to having the goods in your warehouse, you should probably plan for 8-12 weeks as a starting point, and potentially longer for complex sea-freighted orders. Michael plans his seasonal ranges almost 6-9 months in advance. It sounds like a lot, but it avoids a last-minute panic! Always build in some buffer time. Trust me on this one! 😉How Can Eco-Friendly Materials Enhance Your Custom Notebook Line?

Customers increasingly demand sustainable products. Are your notebooks keeping up? Offering eco-options can significantly boost your brand’s appeal and market reach.

Using recycled paper, FSC-certified paper, Kraft covers, soy-based inks, and alternative materials like cork or bamboo can make your custom notebooks more attractive to environmentally conscious consumers.

This is a topic Michael brings up more and more. His customers in Europe, especially, are really tuned into sustainability. And honestly, it’s something we at Panoffices are passionate about too! It’s not just a "nice to have" anymore; for many brands, it’s becoming a "must-have." Offering eco-friendly options isn’t just good for dear old Planet Earth 🌍; it’s smart business.

What Makes a Notebook "Greener"?

It’s about making conscious choices at various stages:

- Paper Power – The Core Component:

- Recycled Paper: This is a big one. Look for high Post-Consumer Waste (PCW) content. It often has a lovely, slightly textured feel. We offer options from 30% to 100% PCW.

- FSC-Certified Paper: The Forest Stewardship Council certification ensures the paper comes from responsibly managed forests. This is a widely recognized and respected standard. Michael often requests FSC paper for his mainstream lines.

- PCF (Process Chlorine Free) or TCF (Totally Chlorine Free) Paper: Bleaching processes can be harmful, so these are better alternatives.

- Alternative Fibers: Things like bamboo paper (fast-growing resource), sugarcane bagasse paper (made from leftover sugarcane pulp), or even cotton paper (made from cotton linters, a byproduct of the textile industry). These can be really interesting!

- Cover Stories – Beyond Basic Board:

- Kraft Paper/Board: Often unbleached and made from recycled content, it has that popular rustic, natural look.

- Recycled Greyboard or Chipboard: For the stiffener in hardcovers.

- Natural Materials:

- Cork: Harvested from cork oak trees without harming them. It’s lightweight, durable, and has a unique texture. We recently sampled a beautiful cork-cover journal for Michael that he really liked.

- Linen or Organic Cotton Fabric: For fabric-covered notebooks.

- Recycled Leather: Made from leather scraps that would otherwise be waste.

- Inks & Adhesives – The Unseen Details:

- Soy-based or Vegetable-based Inks: A more sustainable alternative to traditional petroleum-based inks. They release fewer VOCs (Volatile Organic Compounds).

- Water-based Adhesives: Less harmful than solvent-based glues.

- Binding & Finishing Touches:

- Metal-Free Bindings: Some stitched bindings avoid staples.

- Natural or Recycled Ribbons/Elastics: Options exist for these too!

- Minimal or Recyclable Packaging: Think biodegradable shrink-wrap, or simple paper belly bands instead of full plastic sleeves.

Why Bother? The Benefits are Real!

- Meet Consumer Demand: Shoppers are actively looking for sustainable products.

- Enhance Brand Image: Shows your company is responsible and forward-thinking.

- Differentiation: Can help your products stand out in a crowded market.

- Often, Unique Aesthetics: Eco materials often have a distinct, appealing look and feel. That Kraft paper notebook? It just feels good.

When discussing options with your manufacturer, don’t hesitate to ask about their eco-friendly material sourcing and certifications. It’s a conversation worth having, and it can really add value to your custom notebook line. Michael is even considering a dedicated "eco-range" for next year, which is super exciting!Conclusion

Sourcing custom notebooks is about details and partnership. Choose wisely, communicate clearly, and you’ll create products that truly represent your brand and delight customers. Happy notebook making!