Are you trying to use elegant, lightweight Bible paper for a premium project but finding that color printing is a major hurdle? The thinness that makes it so appealing also causes ink to bleed and look messy, threatening to ruin your entire design. It’s a frustrating roadblock, but there are specialized solutions to bring your vision to life beautifully.

Achieving high-quality color printing on Bible paper requires a specialized approach. Due to its extreme thinness and porosity, you must use specific techniques to avoid ink bleed-through and show-through. The key is to control ink density, use fast-drying UV-cured inks, and partner with a printer experienced in handling lightweight paper stocks. While challenging, advanced methods like UV-offset printing can produce crisp, vibrant color results on even the most delicate Bible paper, making it possible for premium stationery and publishing projects.

To truly master color printing on this unique material, we first need to understand what makes it so special. Bible paper, also known as "scritta paper," has distinct properties that are the source of both its elegance and its printing challenges. Let’s break down the fundamentals, because knowing the paper is the first step to printing on it successfully.

What Exactly Is the Paper Used to Print Bibles?

Ever wondered what makes Bible paper feel so unique and delicate? This isn’t your standard office paper; it’s a specialized material designed for a very specific purpose. You might feel it’s too fragile for high-volume printing, but its properties are actually a marvel of paper engineering. Let’s look at what sets it apart from all other paper types.

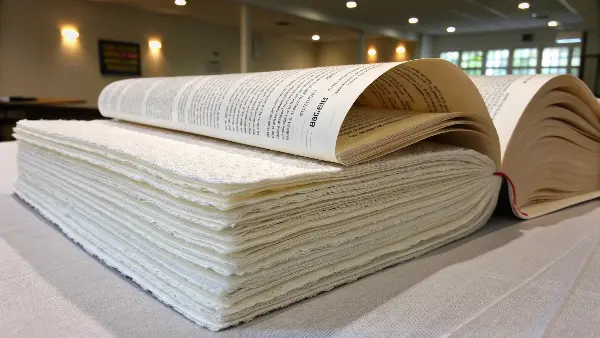

The paper used for Bibles is a type of uncoated, wood-free paper known as Bible paper or scritta paper. It’s renowned for its exceptional thinness, lightweight nature, and high opacity, which prevents text from showing through to the other side. Typically made from high-quality fibers like cotton or linen mixed with chemical pulp, it’s engineered to be both durable and lightweight. This unique combination allows thousands of pages to fit into a single, manageable volume without being transparent.

Bible paper is a true specialty grade in the paper industry. When I work with clients like Michael, a product manager for a European brand, the conversation often turns to creating premium notebooks or planners. He wants something that feels luxurious and substantial but isn’t bulky. This is where my experience with Bible paper comes in. It’s not just one thing; it’s a category of lightweight opaque papers.

Key Components and Characteristics

The magic of Bible paper lies in its composition and manufacturing process. It’s not just about making the paper thin; it’s about making it thin and functional.

- Fibers: While standard paper uses mostly wood pulp, high-quality Bible paper incorporates rag fibers like cotton or linen. These fibers are longer and stronger, giving the paper surprising tear resistance despite its sheerness.

- Fillers: To boost opacity, special mineral fillers are added. Titanium dioxide is a common choice because it scatters light effectively, making the paper less see-through. This is the secret to printing on both sides of such a thin sheet.

- Sizing: Internal sizing agents are mixed into the pulp to reduce the paper’s natural absorbency. This is crucial for controlling how ink behaves on the surface.

This table breaks down how Bible paper compares to standard copy paper.

| Feature | Bible Paper | Standard Copy Paper (80 GSM) |

|---|---|---|

| Material Base | Cotton/Linen & Chemical Pulp | Primarily Wood Pulp |

| Weight | Very Light (25-40 GSM) | Heavier |

| Opacity | High for its weight | Low for its weight |

| Feeling | Silky, delicate, strong | Sturdy, everyday feel |

Understanding these elements is the first step. When a client wants to print on it, I explain that we aren’t just putting ink on paper; we’re interacting with a carefully balanced system of fibers and fillers. This knowledge helps us predict and solve potential printing issues.

Why Is Bible Paper So Incredibly Thin?

You pick up a Bible or a thick dictionary and notice it has over a thousand pages, yet it doesn’t feel impossibly heavy or bulky. The reason is the paper’s incredible thinness. But this isn’t just a random choice; it’s a solution to a significant design problem. The need to pack a massive amount of information into a portable format drove this innovation.

Bible paper is made incredibly thin primarily to reduce the overall bulk and weight of books with a very high page count, like Bibles, dictionaries, and pharmaceutical inserts. If these books were printed on standard paper, they would be impractically large and heavy. The thinness of Bible paper, combined with its high opacity and strength, allows publishers to create compact, portable volumes containing thousands of pages. It’s a functional solution that balances portability with readability and durability.

The thinness of Bible paper is its defining feature, but it’s a decision driven entirely by practicality. Imagine a 1,500-page Bible printed on the 80 gsm paper you use in your office printer. The book would be nearly a foot thick and weigh a ton! The primary goal was, and still is, to make large volumes of text portable and easy to handle. As a manufacturer, I find this "form follows function" principle fascinating.

The Engineering Behind the Thinness

Creating such a thin yet durable sheet is a highly technical process. Papermakers must perfect several stages to achieve this balance.

- Pulp Refinement: The pulp, a mix of wood and rag fibers, is beaten for an extended period. This process fibrillates the fibers, making them flatter and more flexible. This allows them to bond together more tightly into a dense, non-porous sheet. It’s a bit like kneading dough to develop gluten; it changes the material’s fundamental structure.

- Sheet Formation: On the paper machine, the fibers are carefully laid out to form a very uniform, even sheet. Any inconsistency at this stage would result in weak spots or holes, which are unacceptable in such a thin paper.

- Calendering: After the sheet is formed and dried, it’s passed through a series of high-pressure rollers called calenders. This process smoothens and compacts the paper, further reducing its thickness and increasing its density and gloss.

The Impact on Use

The result is a paper that optimizes for page count over everything else. This has direct implications for its use in products beyond Bibles. For stationery buyers like Michael, who might want a 365-day planner that isn’t bulky, Bible paper is an excellent option. It allows for a full year of daily pages in a slim, elegant format. The challenge, of course, is that its thinness makes it unforgiving for certain pens and printing methods—a trade-off we must always manage.

What Is the Typical GSM of Bible Paper?

When discussing paper specifications, the term "GSM" always comes up. It’s a critical number that defines the paper’s weight and, indirectly, its thickness and feel. With Bible paper, the GSM is shockingly low, which can be alarming if you’re used to standard office or book papers. But a low GSM is precisely what makes it fit for its purpose.

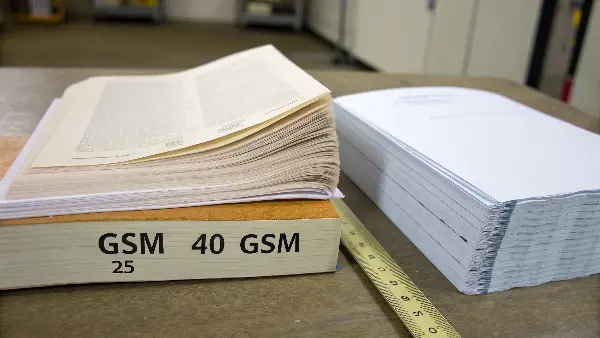

The typical GSM (Grams per Square Meter) of Bible paper ranges from 25 to 40 GSM. Some premium or specialized versions can go as low as 20 GSM or as high as 50 GSM. To put this in perspective, standard office copy paper is usually 80 or 90 GSM, making Bible paper less than half the weight. This extremely low weight is fundamental to its purpose of reducing the bulk of high-page-count books, making it one of the lightest printing papers available.

Whenever I present Bible paper as an option for a new project, the first technical question I get is always about the GSM. A product manager sees "30 GSM" on a spec sheet and immediately thinks of flimsy, transparent tracing paper. My job is to explain that with Bible paper, GSM doesn’t tell the whole story. The opacity and strength are engineered to be far higher than you’d expect for that weight.

Understanding GSM in Context

GSM is a measure of weight, not thickness. While heavier papers are generally thicker, the correlation isn’t perfect. The manufacturing process plays a huge role.

- Low GSM (25-40): This is the classic range for Bibles, dictionaries, and legal texts. At Panoffices, we often use 30-40 GSM paper for premium journals where clients want a high page count without the bulk. For example, a 400-page journal with 40 GSM paper feels much more compact than one with 80 GSM paper.

- Higher-End (40-50 GSM): For deluxe editions or books that might include some simple color illustrations, a slightly heavier Bible paper might be used. This provides better opacity and a more substantial feel while still being significantly lighter than regular bookwove paper.

How GSM Impacts Stationery Design

Choosing the right GSM is a key decision in product development. This table illustrates the trade-offs I often discuss with my clients.

| GSM Range | Pros | Cons | Ideal Use Case |

|---|---|---|---|

| 25-30 GSM | Maximum page count in a slim profile, very lightweight | More show-through, feels very delicate, limited to pencil or ballpoint pen | Compact annual planners, pocket reference guides |

| 30-40 GSM | Good balance of thinness and opacity, surprisingly durable | Still unforgiving for fountain pens or heavy markers | Premium daily journals, lightweight notebooks, Bibles |

| 40-50 GSM | Better opacity, can handle some inks better, more premium feel | Less "thin," adds slightly more bulk | Deluxe edition books, high-end stationery, projects with simple color work |

Understanding these nuances is crucial. A low GSM isn’t a flaw; it’s a feature. The key is to match the right GSM to the product’s intended use and the user’s expectations.

What Technical Hurdles Limit Color Printing on Bible Paper?

So you want to print vibrant, full-color images on super-thin Bible paper? This is where we hit the biggest technical challenges. The very properties that make Bible paper great—its thinness and light weight—also make it a nightmare for conventional color printing. It’s a problem I’ve spent years helping clients navigate.

Color printing on Bible paper is limited by three main technical hurdles: ink bleed-through, show-through, and poor ink holdout. The paper’s thin and porous nature causes liquid ink to soak through to the other side (bleed-through) or be clearly visible from the reverse (show-through). Furthermore, the uncoated surface absorbs ink unevenly, which can lead to muddy colors, loss of detail, and a lack of vibrancy. Standard offset printing methods often oversaturate the paper, making these problems worse.

The dream of putting colorful, saturated images in a lightweight journal or book often crashes against the reality of paper physics. When I first started experimenting with this, the results were disastrous—blotchy images and pages that were completely ruined. We quickly learned that you can’t treat Bible paper like any other stock. The standard playbook for color printing simply doesn’t apply here.

Deconstructing the Printing Problems

Let’s break down exactly why traditional color printing fails on this delicate paper. The issues are interconnected and stem from the paper’s core characteristics.

- Ink Absorption and Bleed-Through: Standard offset inks are oil-based and liquid. When a thin, uncoated sheet of Bible paper hits the press, it acts like a sponge. The ink doesn’t just sit on top; it dives deep into the fibers. When you print four layers of color (CMYK), you’re applying a significant amount of liquid, leading to severe bleed-through.

- Show-Through (Opacity Issues): Even if the ink doesn’t fully bleed through, the high saturation makes the image clearly visible from the back. This is called show-through, and it distracts from the content on the reverse side. Bible paper has high opacity for its weight, but that opacity is designed for black text, not dense fields of color.

- Ink Holdout and Dot Gain: Ink holdout refers to how well the ink sits on the paper’s surface. Because Bible paper has poor ink holdout, the tiny dots of ink that form an image spread out as they absorb. This "dot gain" causes fine details to blur and colors to appear muddy and less saturated.

These challenges mean that simply sending a file to a regular printer and asking for it to be printed on 30 GSM paper will almost certainly lead to disappointment. A specialized approach is non-negotiable.

What Creative Solutions Make Color Printing on Bible Paper Possible?

After outlining all the challenges, you might think high-quality color printing on Bible paper is impossible. It’s definitely difficult, but not impossible. With the right technology, materials, and expertise, you can achieve beautiful results. It’s about working with the paper, not against it. As a supplier, this is where we add the most value.

Creative solutions for color printing on Bible paper center on controlling the ink. The most effective method is using UV-cured inks with UV-offset or UV-LED printing presses. These inks are cured instantly by UV light, so they don’t have time to absorb into the paper, preventing bleed-through. This technique allows for sharp details and vibrant colors. Other strategies include reducing total ink coverage in the design phase and using specialized, highly pigmented inks that require less volume.

I remember the first time I saw a perfect color print on 35 GSM paper. It was a revelation. A partner factory of ours had just invested in a UV-LED press, and we were running tests for a client who wanted detailed botanical illustrations in a planner. The ink sat perfectly on the surface, sharp and vibrant, with zero bleed-through. It proved that technology could solve this long-standing problem.

Key Techniques for Success

Achieving that perfect print requires a combination of pre-press adjustments and specialized printing technology. You can’t just focus on one part of the process.

- UV-Cured Printing: This is the game-changer. UV inks are not liquid in the traditional sense. They are a polymer-based substance that remains in a semi-solid state until exposed to ultraviolet light. On the press, the ink is applied and then instantly cured by a UV lamp. It hardens on the surface before it can soak into the paper’s fibers. This dramatically reduces dot gain and eliminates bleed-through.

- Ink Management in Pre-Press: Before even getting to the press, the design files must be optimized. This involves using an "Under Color Removal" (UCR) technique. Instead of creating gray tones with a mix of Cyan, Magenta, and Yellow, the software replaces them with Black ink. This reduces the total amount of ink applied to the paper, a concept known as Total Area Coverage (TAC). For Bible paper, we aim for a much lower TAC than for standard paper.

- Specialized Ink Formulations: Even within UV inks, there are different formulations. We use high-pigmentation inks designed for uncoated stock. These inks provide excellent color with a thinner ink film, further reducing the risk of show-through.

Here’s a summary of the solution stack we use at Panoffices for these projects.

| Solution | How It Helps | Why It’s Effective |

|---|---|---|

| UV-Offset Printing | Cures ink instantly on the surface. | Prevents ink from absorbing into the paper, stopping bleed-through. |

| Low TAC File Prep | Reduces the total amount of ink used. | Less ink means less show-through and faster, cleaner curing. |

| High-Pigment Inks | Achieves vibrant color with less ink volume. | Minimizes liquid load on the delicate paper fibers. |

By combining these methods, we can confidently offer color printing on Bible paper, turning what was once a limitation into a premium feature for our clients.

Is Bible Paper Always Acid-Free for Longevity?

When creating a product designed to last, like a Bible, a high-end journal, or an archival document, the paper’s longevity is a critical concern. You’ve probably heard the term "acid-free" in relation to archival quality. Does this apply to the delicate, thin paper used for Bibles? It’s a crucial question for any long-term project.

Yes, most modern Bible paper is acid-free and often alkaline-buffered to ensure archival quality and prevent yellowing and degradation over time. Since Bibles and other reference books are intended to last for decades or even centuries, using paper with a neutral or slightly alkaline pH (7.0 or higher) is standard practice. This prevents the acid-induced decay that causes old, cheap paper to become brittle and discolored, ensuring the book’s durability.

I’ve had many conversations with clients who are creating heirloom-quality products. They want to assure their customers that the journal they buy today will still be in good condition for their grandchildren to read. For this reason, we almost exclusively source acid-free Bible paper. The small additional cost is negligible compared to the value it adds in terms of longevity and quality perception.

The Science of Acid-Free Paper

The "acid" in paper historically came from the alum sizing agents used in the manufacturing process. Over time, this acid breaks down the cellulose fibers that give paper its strength, causing it to become brittle and yellow.

- pH Scale and Paper: The pH scale measures acidity and alkalinity. A pH of 7 is neutral. Paper with a pH below 7 is acidic, while paper with a pH above 7 is alkaline. Archival paper is typically in the 7.5 to 9.5 pH range.

- Modern Papermaking: Today, papermakers use synthetic, alkaline sizing agents instead of alum. They also often add an alkaline buffer, like calcium carbonate, to the pulp. This buffer neutralizes acids that the paper might absorb from the environment over its lifetime, offering an extra layer of protection.

Why It Matters for Your Project

Choosing acid-free Bible paper has tangible benefits, especially for premium stationery.

| Feature | Benefit for the Product/Brand |

|---|---|

| Prevents Yellowing | The product maintains its pristine appearance for years, reinforcing its premium quality. |

| Stops Brittleness | Pages won’t easily crack or tear with age, ensuring the journal or book remains usable. |

| Archival Quality | This can be a key marketing point, appealing to customers who value longevity and legacy. |

For any product intended for long-term keeping—be it a religious text, a scientific reference book, or a personal diary—specifying acid-free paper is not just a good idea; it’s a necessity. It’s a guarantee of durability that reflects positively on the brand and provides real value to the end user. When in doubt, always ask your supplier to confirm the paper is acid-free and buffered.

Conclusion

In short, printing in color on Bible paper is a specialized craft that balances technical limitations with innovative solutions. While its thinness an presents challenges like bleed-through, modern UV printing technology and careful ink management have made vibrant, durable color possible. By understanding the paper’s unique properties, you can create stunning, lightweight products that last a lifetime.