Are you trying to understand the intricate process of printing the Quran? It can be overwhelming to balance the need for modern efficiency with the deep respect required for this sacred text. You want to produce a beautiful, error-free copy but are unsure where traditional craftsmanship meets today’s technology.

Printing the Quran involves a blend of traditional respect and modern precision. Key steps include digital typesetting of the Uthmanic script, rigorous proofreading by religious scholars, high-resolution plate making, and printing on premium, acid-free paper using offset or digital presses. The process finishes with specialized binding and cover decoration, ensuring every copy is both accurate and durable. This meticulous combination honors the Quran’s sacred status while leveraging technology for quality and accessibility.

The journey of producing a printed Quran is unlike any other book project I’ve handled in my career. It’s a profound responsibility that goes far beyond just ink and paper. Every decision, from the weight of the paper to the type of binding, is made with reverence and a commitment to perfection. This guide will walk you through this unique process, sharing insights from my experience to help you appreciate the craft. Let’s explore how we honor tradition while embracing the best of modern manufacturing.

What Makes Printing the Quran a Unique and Sacred Task?

Have you ever wondered what sets Quran printing apart from any other high-quality book production? The process is steeped in religious significance, where every step is a form of worship. The fear of introducing even a minor error, which could alter the holy text, creates a level of pressure unheard of in commercial printing.

Printing the Quran is unique due to its sacred status in Islam, which demands absolute textual accuracy and profound respect. Unlike other books, there is zero tolerance for error; every letter and diacritical mark must be perfect. The production requires specialized knowledge of the Uthmanic script, consultation with religious scholars for proofreading, and a spiritually mindful approach from everyone involved. It’s not just manufacturing; it’s a sacred duty to preserve and honor the divine word.

When a client like Michael, who is accustomed to sourcing high-end stationery, first inquires about Quran printing, the conversation shifts dramatically. We move from discussing design trends and material costs to the deep-seated protocols of handling a holy text. The entire supply chain must understand and respect these protocols. For instance, the physical proofs and printing plates are handled with special care, and often, waste materials are disposed of in a respectful manner, sometimes through burial or burning, rather than simple recycling. This spiritual dimension is woven into the very fabric of the production workflow, making it a project that demands integrity and expertise beyond the technical. It’s a responsibility we take very seriously, understanding that we are helping to create a vessel for divine revelation that will be cherished in homes, mosques, and schools for generations.

The Pillars of Quran Printing

The entire process rests on a foundation of reverence and precision. It’s not about speed or volume in the same way as other printing jobs. We break it down into key areas of focus to ensure nothing is overlooked.

- Absolute Accuracy: The primary goal is to produce a text that is a 100% faithful reproduction of the Uthmanic codex. This involves multiple layers of verification.

- Cultural and Scriptural Expertise: The team must be fluent in classical Arabic and understand the specific rules of the Uthmanic script, which differs from modern Arabic typography.

- Respectful Handling: Every person involved, from the typesetter to the binder, must approach the task with a clean state of mind and body, following specific cultural and religious etiquette.

| Pillar of Production | Core Requirement | Practical Implementation |

|---|---|---|

| Textual Integrity | Zero-error tolerance | Multi-stage proofreading by certified Islamic scholars (Hafiz). |

| Typographical Precision | Correct Uthmanic script | Use of specialized, verified digital fonts; meticulous kerning of letters. |

| Material Sanctity | Use of pure, high-quality materials | Choosing premium, durable paper and ensuring a clean production environment. |

| Process Reverence | Mindful and respectful handling | Training staff on the religious significance and proper handling protocols. |

This holistic approach ensures that the final product is not just a book, but an object of spiritual value, worthy of its sacred content. It’s this deep understanding that separates authentic Quran printers from standard book manufacturers.

What Were the Traditional Methods of Reproducing the Quran?

Before modern presses existed, how was the Quran’s perfect text passed down through generations? The task fell to highly skilled artisans who dedicated their lives to this sacred work. Their painstaking labor ensured the holy book was preserved and beautified, but it was an incredibly slow and exclusive process.

Traditionally, the Quran was reproduced manually by master calligraphers (khattat). These scribes would spend months or even years meticulously handwriting each copy on parchment or paper. The pages were often decorated with intricate geometric patterns and gold leaf, a process known as illumination (tazhib). This made each Quran a unique masterpiece of devotional art, but it also made them extremely rare and expensive, accessible only to a select few.

I once had the privilege of examining a centuries-old Quran manuscript. Holding it, you could feel the weight of history and the devotion poured into its creation. Every curve of the script and fleck of gold told a story of faith and incredible skill. These traditional methods set a standard for beauty and reverence that modern printing still strives to emulate. While we now use machines for speed and precision, the goal remains the same: to produce a text that is worthy of its divine origin. The legacy of those calligraphers informs our choices in typography, page layout, and design today, as we aim to capture a fraction of that timeless beauty.

From Pen to Press: The Evolution of Reproduction

The journey from a single handwritten copy to mass-produced printed versions was a slow and careful evolution. Each step forward was measured against the core requirement of maintaining the sanctity and accuracy of the text. Early printing methods were rudimentary and often struggled to capture the elegant flow of Arabic script.

- The Age of the Scribe: For over a millennium, the

katibor calligrapher was the sole guardian of the text’s reproduction. Their role was a highly respected spiritual and artistic profession. - The Introduction of Woodblock Printing: Some of the earliest forms of printing in the Islamic world used woodblocks. An entire page of text was carved in reverse onto a block of wood, which was then inked and pressed onto paper. This was still laborious and lacked the fine detail of calligraphy.

- Lithography’s Breakthrough: The invention of lithography in the 19th century was a major step forward. This technique allowed for the calligrapher’s original handwriting to be transferred to a printing stone, preserving the natural, fluid style of the script far better than movable type could.

| Method | Description | Key Advantage | Key Disadvantage |

|---|---|---|---|

| Manual Calligraphy | Handwriting the text with a reed pen (qalam). |

Unmatched artistic beauty and spiritual connection. | Extremely slow, expensive, and prone to human error. |

| Woodblock Printing | Carving a full page onto a wooden block. | Allowed for multiple identical copies to be made. | Loss of calligraphic detail; blocks wore out quickly. |

| Lithography | Printing from a flat stone or metal plate. | Faithfully reproduced the calligrapher’s hand. | Still a relatively slow process compared to modern methods. |

This historical context is crucial. It shows that the desire to share the Quran more widely has always been balanced with the need to preserve the aesthetic and spiritual integrity established by the first scribes.

How Do Modern Printing Technologies Ensure Accuracy and Beauty?

With the immense responsibility of printing a perfect Quran, how can we trust modern machines to get it right? People often worry that industrial production might lose the soul and reverence of traditional methods. They question if technology can truly deliver both flawless accuracy and aesthetic grace for such a sacred text.

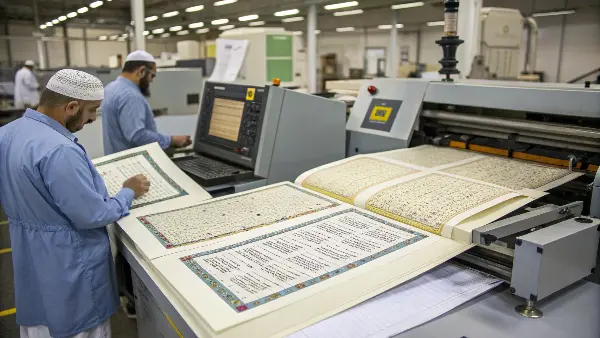

Modern printing ensures Quranic accuracy and beauty through a combination of digital precision and high-end production machinery. It starts with validated digital files of the Uthmanic script, which are then used to create flawless printing plates via Computer-to-Plate (CTP) technology. High-speed offset presses reproduce the text with perfect consistency and sharpness on premium paper, while digital printing offers superb quality for smaller, customized runs. These technologies eliminate human error in transcription and guarantee uniformity across millions of copies.

I’ve seen firsthand how technology transforms this sacred task. During a press check for a large Quran order, I watched as the offset machine produced thousands of perfectly identical sheets per hour. The digital system flagged the slightest imperfection in ink density, an issue that would be invisible to the naked eye. This level of precision is something a manual scribe, no matter how skilled, could never guarantee. Modern technology isn’t about replacing the human touch; it’s about channeling that reverence into a system that ensures a perfect outcome every single time, making the holy text accessible to millions without compromising its integrity.

Comparing Offset and Digital Printing for the Quran

Choosing the right printing technology is a critical decision. It depends on factors like the quantity needed, the level of customization, and the desired quality. Both offset and digital printing have their place in modern Quran production, and we often guide clients on which method best suits their project.

- Offset Printing: This is the workhorse for large-scale production. It uses printing plates to transfer ink onto paper and is extremely cost-effective for runs of thousands or millions of copies. The quality is exceptionally high and consistent.

- Digital Printing: This method prints directly from a digital file without the need for plates. It’s ideal for smaller quantities, personalized editions (e.g., with a family name or a mosque’s logo), or for creating proof copies. The quality now rivals offset for many applications.

| Feature | Offset Printing | Digital Printing |

|---|---|---|

| Best for Volume | High (1,000+ copies) | Low to Medium (1-1,000 copies) |

| Setup Cost | High (due to plate creation) | Low |

| Cost Per Copy | Very low at high volumes | Stays relatively constant |

| Turnaround Time | Longer (due to setup) | Fast |

| Customization | Not possible (all copies are identical) | Excellent (each copy can be different) |

| Quality | Superior for fine details and color consistency | Excellent, and continuously improving |

For a global distribution project, we would always recommend offset printing to maximize quality and minimize cost per unit. However, if a client needs a special limited edition with a custom cover, digital printing provides the flexibility to do so beautifully and affordably.

What Key Materials Define a High-Quality Printed Quran?

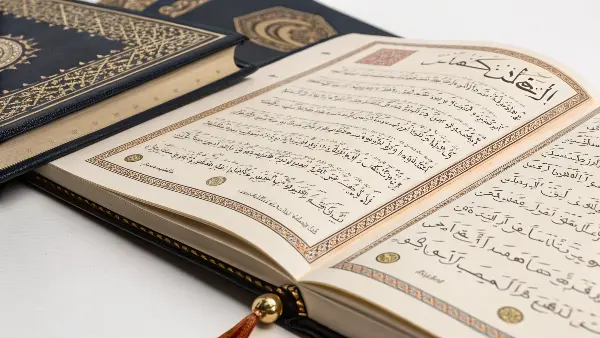

When you hold a truly well-made Quran, you notice it’s not just the print that stands out. The feel of the paper, the richness of the ink, and the sturdiness of the binding all contribute to the experience. Choosing the wrong materials can turn a sacred text into a disposable item, failing to honor its eternal message.

A high-quality Quran is defined by three key materials: premium, acid-free paper for longevity and opacity; deep, stable ink that won’t fade or smudge; and a durable, aesthetically pleasing cover and binding. The paper is typically lightweight yet strong (60-80 gsm) to keep the book manageable. The ink must be rich black for crisp calligraphy, and the binding—often Smyth-sewn—ensures the book lies flat and withstands decades of use.

I often explain to clients like Michael that material selection is a form of respect for the text. We source special "Bible paper" or lightweight offset paper that prevents the text from showing through on the other side, which is crucial for a comfortable reading experience. The choice of cover material, from genuine leather to embossed synthetic fabrics, and finishing touches like gilded edges or a ribbon marker, all elevate the final product. These aren’t just cosmetic choices; they are functional decisions that protect the sacred words within and provide a dignified reading experience for the user.

A Deeper Look at Paper, Ink, and Binding

Each component plays a vital role in the final product’s quality, longevity, and feel. We meticulously specify and test each material to ensure it meets our exacting standards. A cheap material choice can compromise the entire project, no matter how perfect the printing process is.

-

Paper Selection: The paper is the foundation. It must be strong enough to handle repeated page-turning yet light enough to keep the book from becoming overly heavy.

- GSM (Grams per Square Meter): For Qurans, a lower GSM (60-80) is often preferred to manage the book’s thickness.

- Opacity: High opacity is critical to prevent "show-through," which would make the text difficult to read.

- Acidity: Acid-free paper is essential to prevent yellowing and deterioration over time, preserving the book for future generations.

-

Ink Quality: The ink carries the sacred words.

- Pigment vs. Dye: We use high-density pigment-based black ink that sits on top of the paper fibers, creating exceptionally sharp and crisp text that is resistant to fading.

- Drying and Smudging: The ink must dry quickly and permanently bond with the paper to prevent smudging during binding and handling.

-

Binding and Cover: The binding holds everything together and protects the pages.

- Smyth-Sewn Binding: This is the gold standard. Groups of pages (signatures) are stitched together with thread before being glued to the cover spine. This allows the book to lie flat when open and is incredibly durable.

- Cover Materials: Options range from embossed hardcovers and flexible synthetic leather to premium genuine leather, often adorned with foil stamping or debossing.

| Component | Specification | Why It Matters |

|---|---|---|

| Paper | 70 gsm, acid-free, high-opacity cream paper | Ensures readability, longevity, and a pleasant tactile feel. |

| Ink | High-density, fast-drying pigment black | Creates sharp, permanent text that won’t fade or smudge over time. |

| Binding | Smyth-sewn with a reinforced hardcover | Provides maximum durability and allows the book to lay flat for easy reading. |

These material choices are not arbitrary; they are a deliberate investment in creating a Quran that is as enduring as its message.

What Are the Critical Quality Control Stages in Quran Production?

Given the absolute zero-error policy, how do we guarantee that not a single mistake makes it into the final printed Quran? A standard printing quality check is not enough. Without a rigorous, multi-layered inspection process, a small error could be replicated millions of times, which is an unacceptable outcome for this sacred project.

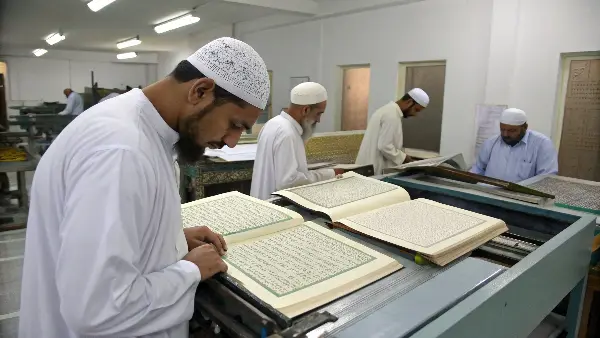

The critical quality control stages in Quran production are multi-faceted. First, the digital text is proofread multiple times by committees of certified religious scholars (Hafiz) before any plates are made. Second, during the press run, a "press check" is performed where initial sheets are meticulously compared against the signed-off proof for errors, color consistency, and print clarity. Finally, post-production checks inspect the binding, cover application, and finishing details of randomly selected copies to ensure perfection.

I will never forget the intensity of a Quran press check. The room is silent except for the hum of the press. The print manager, the client’s representative, and a religious scholar huddle under a calibrated light, comparing the freshly printed sheet to the final proof. They check not just for typos, but for broken letters, ink spots, or any other imperfection. The approval to continue the print run is only given when all parties are 100% satisfied. This painstaking process is repeated for every section of the book, ensuring that our commitment to perfection is upheld from the first copy to the last.

A Step-by-Step Quality Assurance Framework

To eliminate any possibility of error, we implement a systematic quality assurance framework that integrates checkpoints at every major phase of production. This is non-negotiable for any Quran printing project we undertake. It builds trust and ensures peace of mind for our clients.

-

Phase 1: Pre-Press Verification

- This is the most critical stage for textual accuracy. The digital files undergo multiple rounds of proofreading. We often use software to compare files digitally, but the final sign-off always comes from human experts—scholars who have memorized the Quran. They check every verse, letter, and diacritical mark.

-

Phase 2: On-Press Inspection

- Once printing begins, quality checks are constant. The first few hundred sheets, known as the "make-ready," are carefully inspected. We use a densitometer to measure ink consistency and a loupe to check for registration and sharpness. Sheets are pulled and checked periodically throughout the entire print run.

-

Phase 3: Post-Press and Bindery Checks

- After printing, the job is not over. The bindery process is monitored to ensure pages are collated in the correct order, the stitching is tight, and the covers are perfectly aligned. A final random inspection of finished books is done before packing and shipping.

| Stage | Key Activity | Purpose |

|---|---|---|

| Digital Proofing | Multiple rounds of reading by Islamic scholars. | To guarantee 100% textual accuracy before printing. |

| Plate Making | Digital files are checked again after conversion. | To ensure no data was corrupted during the CTP process. |

| Press Check | On-site approval of the first printed sheets. | To verify print quality, color, and registration against the proof. |

| Bindery Check | Inspecting collating, sewing, and cover application. | To ensure the book is assembled correctly and is durable. |

| Final Inspection | Random sampling of finished, packed books. | To catch any final defects before the product leaves our facility. |

This rigorous, multi-stage process is how we fulfill our solemn duty to produce a flawless Quran that honors its sacred content and serves the faithful community.

Conclusion

Ultimately, printing the Quran is a unique convergence of faith, art, and technology. It requires a deep respect for tradition, an unwavering commitment to accuracy, and the precise execution that only modern manufacturing can provide. By carefully selecting materials and implementing rigorous quality controls, we can produce beautiful, durable, and error-free copies of the holy text for a global audience.