Struggling to find a manufacturer who truly understands the delicate balance of reverence and durability required for religious books? The production of sacred texts involves unique challenges, from paper thinness to binding longevity, where a single mistake can compromise the entire project. You need a partner who respects the material’s significance and has the technical expertise to deliver perfection.

Producing high-quality religious books requires a specialized approach focusing on specific materials, binding techniques, and printing precision. Key standards include using thin, opaque paper (like Bible paper), employing durable Smyth-sewn binding so the book lays flat, and utilizing high-precision printing to ensure text clarity without bleed-through. Special features like gilded edges, ribbon markers, and premium cover materials (leather or high-grade faux leather) are also crucial for creating a book that is both beautiful and built to last generations.

The process of creating a religious book is unlike any other in publishing. It’s a craft where tradition meets technology. Each decision, from the weight of the paper to the thread in the binding, is made with both the reader’s experience and the text’s sacredness in mind. We’ve spent years mastering this process, understanding that these books are not just read; they are cherished companions for life. Let’s explore what it takes to get it right.

Which Materials Best Preserve the Sanctity and Durability of Religious Texts?

Choosing the right materials feels like a monumental task, doesn’t it? You want a book that feels sacred and valuable, yet it also needs to withstand daily use for years, even decades. Using standard paper and cover materials just won’t do; they can lead to pages tearing, text fading, or the cover quickly showing wear, diminishing the user’s experience and connection.

To ensure longevity and reverence, the best materials are a combination of lightweight, acid-free Bible paper and premium cover options like genuine leather, durable polyurethane (PU) leather, or elegant linen cloth. Bible paper, typically 28-40 gsm, provides high opacity to prevent text show-through while keeping the book slim. The cover material not only protects the pages but also defines the book’s tactile and aesthetic character, making it a cherished item for the owner.

The material selection is the foundation of a religious book’s quality. I’ve worked on many projects where the client, like Michael in Germany, needed to balance tradition with modern practicalities and budget. The choice between genuine leather and a high-quality PU leather, for example, is a common discussion. We look at the target audience, the desired price point, and the overall feel the brand wants to convey. It’s about making an informed choice that honors the text inside.

The Heart of the Book: Paper Selection

The paper is arguably the most critical component. Unlike a novel, a religious text often contains a vast amount of content that must fit into a manageable volume. This is where "Bible paper" comes in. It’s a specific type of offset paper known for its thinness and strength. Its key feature is its high opacity relative to its low weight (measured in grams per square meter, or gsm). This prevents the text on the reverse side from showing through, which is essential for a good reading experience. We typically use acid-free paper to prevent yellowing over time, ensuring the text remains clear for generations.

The First Impression: Cover Materials

The cover does more than just protect the pages; it sets the tone for the entire book. It’s the first thing a person sees and touches. Here’s a breakdown of the common choices we offer our clients:

| Material | Feel & Aesthetics | Durability | Best For |

|---|---|---|---|

| Genuine Leather | Premium, traditional, soft. Develops a unique patina over time. | Very high, but requires care. | Heirloom editions, premium gifts. |

| PU Leather | Consistent look, smooth feel. Can mimic real leather well. | Excellent, resistant to wear and moisture. | Daily use, vegan-friendly options. |

| Linen/Cloth | Modern, sophisticated, textural. | Good, but can be prone to staining if not treated. | Contemporary designs, special editions. |

For a product manager like Michael, understanding these trade-offs is key. We often produce samples using different materials so he can physically feel the difference and see how each one takes to debossing or foil stamping for the cover design.

What Binding Techniques Ensure a Religious Book Lasts for Generations?

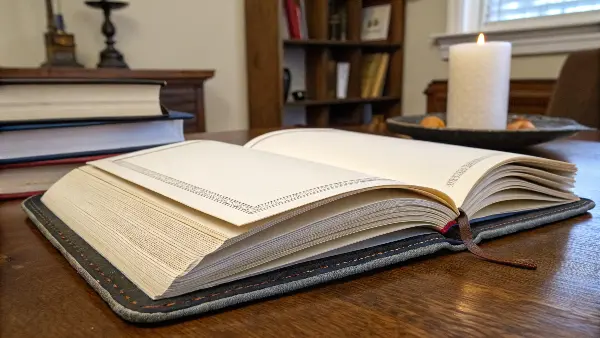

Have you ever opened a thick book, only to have it refuse to stay open or hear the spine crack? For a religious text used for daily study, this is a major failure. Standard gluing methods can’t handle the repeated stress, leading to loose pages and a broken spine. The book becomes frustrating to use, defeating its purpose as a tool for reflection and study.

The gold standard for durable, long-lasting religious books is Smyth-sewn case binding. This method involves stitching individual signatures (groups of folded pages) together with thread before attaching them to a hardcover case. This allows the book to lay completely flat when open, reducing stress on the spine and preventing pages from ever falling out. It’s the most reliable technique for a book intended for a lifetime of use.

I remember a project where we were developing a new line of study Bibles. A key requirement was that the book needed to lay perfectly flat on a desk, even when opened to the very first or last page. Glued bindings, known as "perfect binding," just couldn’t achieve this. By demonstrating the flexibility and strength of a Smyth-sewn sample, we showed the client why it was the only viable option. It’s an investment in quality that users notice and appreciate every single time they open the book.

The Foundation of Strength: Smyth-Sewing

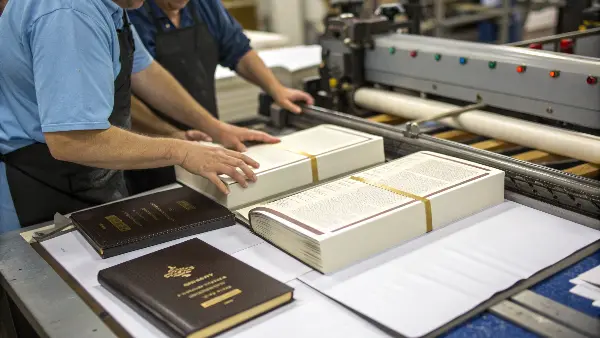

Smyth-sewing is a process deeply rooted in traditional bookmaking. Here’s how it works:

- Folding into Signatures: The printed sheets are folded into small booklets called signatures, typically containing 16 or 32 pages.

- Stitching the Signatures: A specialized machine sews through the fold of each signature, linking them together with thread. This creates a single, strong, and flexible block of pages.

- Creating the Book Block: All the stitched signatures are pressed and glued along the spine to form a cohesive "book block."

This method is superior because the pages are physically linked with thread, not just held by a layer of glue. This flexibility is what allows the book to lay flat.

The Protective Shell: Case Binding

Once the sewn book block is ready, it needs its hardcover. This process is called case binding.

- Making the Case: The cover material (leather, cloth, etc.) is wrapped around and glued to thick, rigid boards.

- Attaching the Block: The book block is then affixed to the case using strong adhesive and endpapers—the durable sheets of paper you see on the inside of the cover.

The combination of a sewn book block and a sturdy hardcover case creates a book that is incredibly resilient. It can withstand being opened and closed thousands of time without compromising its structure. For any serious religious book project, this is the technique we recommend above all others.

How Does Precision Printing Uphold the Integrity of Sacred Scriptures?

Printing on the extremely thin paper used for religious books presents a significant technical challenge. If the ink is too heavy or the pressure isn’t perfectly calibrated, you get "bleed-through," where the text is visible from the other side. This makes reading difficult and strains the eyes, detracting from the sacredness of the text. An improperly printed scripture can feel cheap and disrespectful.

To uphold the integrity of scriptures, precision printing is essential. This involves using specialized, high-opacity inks and calibrating the printing press to apply the perfect amount of ink without saturating the thin Bible paper. We also use "line-on-line" printing, where the lines of text on both sides of a page are perfectly aligned. This significantly reduces show-through and creates a clean, readable page, preserving the sanctity of the text.

I once had a client who was very concerned about readability, especially for an older audience. They were commissioning a large-print edition and wanted to ensure the text was as clear as possible. We ran several test prints, adjusting the ink density and comparing the results of standard printing versus line-on-line alignment. Presenting the physical samples made the difference obvious. The line-on-line version was immediately approved because it offered a superior reading experience, which was their primary goal.

The Art of Ink and Pressure

Printing on 30 gsm paper is not the same as printing on standard 80 gsm office paper. It requires a delicate touch.

- Ink Control: We use inks with a high pigment concentration but low viscosity. This allows for dark, crisp text without requiring a thick layer of ink that would soak through the page. The ink must also be quick-drying to prevent smudging as the paper moves through the press at high speed.

- Press Calibration: Our press operators are highly skilled technicians. They meticulously adjust the pressure between the printing plate and the paper. Too much pressure will push the ink through the fibers, while too little will result in faded or incomplete characters. It is a constant balancing act that requires expertise and attention to detail.

Perfect Alignment: The Line-on-Line Technique

This is a subtle but powerful technique that dramatically improves readability. In standard printing, the text on one side of a page is placed without regard to the text on the other. With line-on-line printing, the layout is precisely calculated so that each line of text sits directly over a line on the reverse side. The slight shadow of the ink from the other side is "hidden" behind the printed text you are reading. This clever alignment tricks the eye and makes the paper appear more opaque than it actually is, resulting in a cleaner, more pleasant reading experience.

Typography and Layout

The choice of font (typeface) and its size are also critical. For religious texts, highly readable serif fonts like Garamond or Minion Pro are often preferred because their small "feet" guide the eye along the lines of text. We work with clients to select a font and size that is both elegant and functional, ensuring every word is clear and easy to read.

What Special Features Can Elevate a Religious Book from a Text to a Treasure?

A standard printed book can feel impersonal, but a religious text should feel like a personal, cherished possession. Without thoughtful finishing touches, even a well-made book can lack the special quality that makes it a meaningful gift or a family heirloom. You’re looking for features that add beauty, functionality, and a sense of reverence to the final product.

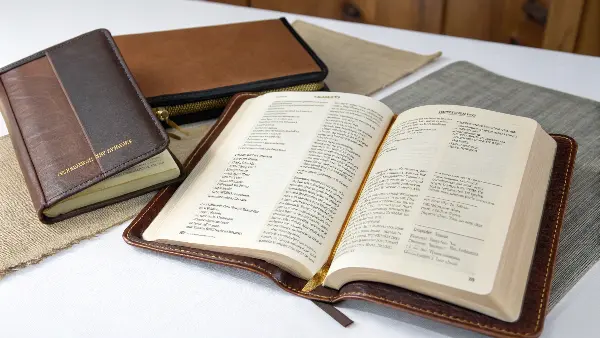

To elevate a religious book, incorporate special features that enhance both its beauty and usability. This includes decorative foil stamping on the cover, elegant gilded or sprayed page edges, multiple ribbon markers for easy place-holding, and functional thumb indexing for quick navigation. These details transform a simple book into a treasured object, perfect for gifting or personal devotion, and signal a high level of quality and care in its creation.

Working with product managers like Michael is always exciting because this is where we get to be creative. We once developed a special edition for a publisher that included a custom-debossed logo on the cover, two-tone ribbon markers matching the brand’s colors, and unique art-gilded page edges with a subtle pattern. These weren’t just random additions; each feature was chosen to reinforce the brand’s identity and create a truly unique product. This attention to detail is what sets a premium book apart in a crowded market.

Decorative Cover Enhancements

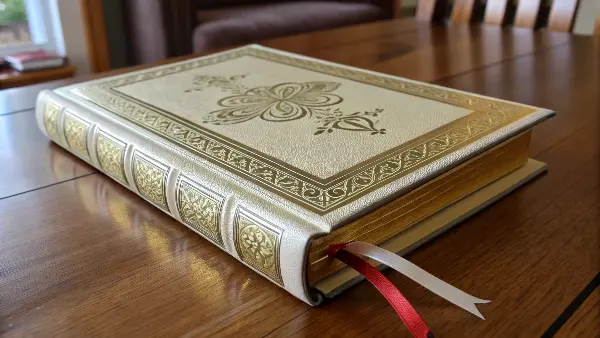

The cover is a canvas for expressing the book’s value.

- Foil Stamping: This process uses heat and pressure to apply a thin layer of metallic or colored foil to the cover. It’s perfect for titles, symbols, or decorative borders, adding a touch of elegance and light-catching beauty. Gold and silver are classic, but a wide range of colors is available.

- Debossing/Embossing: Debossing presses a design into the cover material, creating an indentation. Embossing raises the design. Both add a sophisticated, tactile dimension to the cover. Combining a debossed area with foil stamping can create a stunning effect.

Beautiful and Functional Edges

The edge of the book block offers a unique opportunity for enhancement.

- Edge Gilding: This is the classic application of gold or silver foil to the three edges of the book block. It protects the pages from moisture and dust and gives the book a luxurious, jewel-like appearance.

- Sprayed Edges: For a more modern look, the edges can be sprayed with a solid color, often to match the cover or ribbon markers.

- Thumb Indexing: For Bibles and other reference texts, die-cut notches can be made in the fore-edge of the book, labeled with the names of the different books or sections. This is a purely functional feature that users find incredibly helpful for quick navigation.

Practical Interior Additions

Finally, features inside the book can greatly improve the user experience.

- Ribbon Markers: One ribbon is standard, but adding two or three in different colors allows the user to mark multiple passages at once—for instance, a daily reading, a favorite verse, and the current sermon topic.

- Presentation Pages: Including specially designed pages at the front for gift inscriptions or recording family history (births, marriages) instantly turns the book into a potential family heirloom.

Conclusion

In religious book manufacturing, every detail matters. From the thinness of the paper and the strength of the Smyth-sewn binding to the precision of the printing and the elegance of foil stamping, each element works together. The goal is to create a book that is not only durable for daily use but also a beautiful, reverent object.