Choosing the right binding for your stationery products can feel like a minefield, especially when profit margins are tight, right? You want quality, but cost is king for wholesale.

For wholesale stationery, the most cost-effective binding depends heavily on page count and volume: saddle stitch is cheapest for thin items, while perfect binding offers a good balance for thicker notebooks in bulk.

As a stationery buyer like Michael, you’re constantly juggling aesthetics, functionality, and – critically – price. The binding of a notebook, planner, or journal is a huge part of its appeal and usability, but it also significantly impacts the final cost. I’ve seen it time and again at Panoffices; a client has a brilliant design, but then we hit the binding discussion, and suddenly the budget gets tricky. So, let’s break down the common binding types from a cost perspective. I want to help you make informed decisions that keep your products competitive and your finance department happy. This isn’t just about saving pennies; it’s about maximizing value.

What is the cheapest way to bind documents?

Trying to keep costs rock-bottom for a promotional booklet or a thin handout? You need the most economical binding without it looking totally shoddy.

For documents with a low page count (typically under 48-64 pages, depending on paper thickness), saddle stitching is almost always the cheapest and quickest binding method.

Okay, let’s talk about the absolute entry-level when it comes to cost. If you’re producing something like a thin product catalog, a simple event guide, or a small promotional notebook with very few pages, then saddle stitching is your champion. I mean, it’s the go-to for a reason! Think about those little information booklets you pick up, or even some comic books – that’s usually saddle stitch.

How does it work? It’s super simple: pages are printed, collated, folded in half, and then staples are driven through the spine along the fold. "Saddle" refers to how the collated sheets drape over a saddle-like apparatus during the stapling process. Because the process is so straightforward and uses minimal materials (just a couple of wire staples), it’s very fast to produce in bulk, which directly translates to lower costs.

Now, "cheapest" doesn’t mean "bad." For its intended purpose, saddle stitching is great. It allows the booklet to lay relatively flat, especially with fewer pages. However, it’s not suitable for thick documents because the staples can’t effectively hold many pages, and the booklet won’t close properly – it’ll spring open, which Michael would definitely flag in a product review. Also, there’s no printable spine, so if you need branding on the spine, this isn’t your method. For some of Panoffices’ basic notepads or thin marketing materials, this is the method we’d recommend to keep unit costs down. It’s effective, efficient, and does the job for lightweight applications.

What is the cheapest book binding method?

Need to bind a proper book or a thicker notebook economically, but saddle stitching won’t cut it? You’re looking for that sweet spot of affordability and a professional look.

For "books" or notebooks with more pages, perfect binding often becomes the most cost-effective method, especially at higher volumes, offering a professional look with a printable spine.

So, saddle stitching is great for thin items, but what if you’re producing something more substantial, like a softcover journal, a course workbook, or a trade paperback? You need something that looks and feels more like a "book." This is where perfect binding (also known as adhesive binding) often comes in as the most economical choice for higher page counts.

Think of most softcover books you see in a bookstore – that’s perfect binding. The process involves stacking all the printed pages to form a block. The spine edge of this block is then roughened (or "milled") to create a surface that adhesive can grip onto. Hot melt EVA (Ethylene Vinyl Acetate) glue or, for better durability and flexibility, PUR (Polyurethane Reactive) glue is applied to the spine, and then the cover is wrapped around the page block and pressed firmly. PUR glue is generally preferred for its strength and ability to lay flatter, though it might add a tiny bit to the cost.

The big advantages? You get a neat, flat spine that can be printed on – essential for branding when the book is on a shelf. It looks very professional. Cost-wise, while it’s more expensive than saddle stitching, it’s significantly cheaper than hardcover or even some mechanical bindings once you get into decent print volumes. The setup is more involved, but per unit, it scales well. Michael often specs perfect binding for many of his company’s standard notebooks and journals where a good balance of quality, appearance, and cost is needed. We at Panoffices produce tons of perfect-bound items; it’s a real workhorse in the industry. The main drawback is that perfect-bound books don’t naturally lay completely flat, which can be a concern for some types of notebooks, like planners.

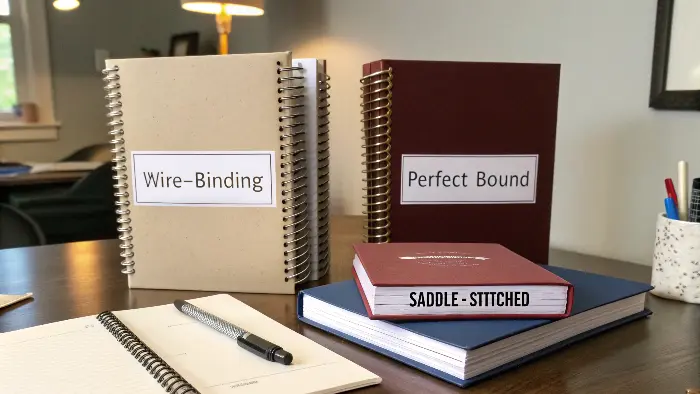

What are the three types of binding?

Feeling lost in a sea of binding terms like Wire-O, case bound, PUR? Understanding the main categories can make choosing the right option much less confusing.

The three main categories of binding are generally mechanical (like spiral or Wire-O), adhesive (like perfect binding), and sewn (like saddle stitch or case/hardcover binding).

It’s easy to get bogged down in jargon, isn’t it? When Michael first started sourcing, he said he had a whole glossary just for printing and binding terms! But really, most binding methods fall into a few broad categories. Understanding these helps you narrow down your choices pretty quickly. Let’s break them down in a simple way:

- Mechanical Binding: This is where pages are held together by a mechanical device.

- Spiral/Coil Binding: A continuous plastic or metal coil is threaded through punched holes along the spine. Pros: Lays completely flat, can fold back on itself, durable coil. Cons: Can look less formal, coil can get crushed if metal. Cost: Mid-range, depends on coil material and diameter.

- Wire-O Binding (or Twin Loop/Double Loop): Pairs of wire loops are clamped through punched holes. Pros: Lays completely flat, can fold back, looks more professional than plastic spiral. Cons: Wires can get bent, more expensive than plastic spiral. Cost: Mid-to-upper mid-range. Michael often prefers Wire-O for Panoffices planners because of the lay-flat functionality combined with a premium feel.

- Adhesive Binding: Pages are glued together at the spine.

- Perfect Binding: We’ve talked about this – pages glued to a wraparound cover. Pros: Professional look, printable spine, cost-effective for volume. Cons: Doesn’t lay perfectly flat. Cost: Lower-mid range, especially in bulk.

- Sewn Binding: Pages are literally sewn together.

- Saddle Stitch: As discussed, staples (which are a form of wire stitching) through the fold. Pros: Cheapest for low page counts, lays flat. Cons: Limited page count. Cost: Lowest.

-

Section Sewn (Smyth Sewn) / Case Binding (Hardcover): Pages are folded into sections (signatures), which are then sewn together. This sewn book block is then glued into a hard, rigid cover (case). Pros: Most durable, highest perceived value, can lay relatively flat. Cons: Most expensive, more complex production. Cost: Highest. This is for your premium, long-lasting products.

Here’s a quick table to help visualize:Binding Type Lay Flat? Durability Printable Spine? Typical Cost Best For Saddle Stitch Yes (for thin) Low-Medium No Lowest Booklets, thin magazines, zines Spiral/Coil Yes, 360° Medium-High No Mid Workbooks, manuals, everyday notebooks Wire-O Yes, 360° Medium-High No Mid-High Planners, premium notebooks, reports Perfect Binding No (partially) Medium Yes Low-Mid Softcover books, journals, thicker magazines Case Bound (Sewn) Yes (relatively) Highest Yes Highest Premium books, ledgers, special editions Understanding these categories makes it much easier to talk to suppliers like Panoffices and specify what you’re looking for. You can say, "I need a lay-flat option, what mechanical bindings do you offer?" and we can guide you from there.

What is the alternative to spiral binding?

Love the lay-flat feature of spiral binding but want a different look or feel, perhaps something more upscale or just… not spiral? There are options!

Alternatives to spiral binding include Wire-O (more premium, still lays flat), sewn lay-flat binding for a high-end feel, or even some flexible perfect binding for partial lay-flat.

Spiral binding is super functional, no doubt. That 360-degree fold-back and perfectly flat opening is hard to beat for usability, especially for notebooks you write in constantly. But I get it, sometimes the plastic coil look isn’t quite right for a particular product, or maybe you just want to explore other options that offer similar lay-flat benefits. Michael sometimes asks us this when he’s developing a new premium planner range for his brand.

So, what else is out there?

- Wire-O Binding: This is often the first alternative people think of. Instead of a continuous plastic coil, Wire-O uses double-loop metal wires. It still allows the notebook to lay perfectly flat and fold back on itself. The metal gives it a more professional, often perceived as higher-quality, look than plastic spiral. It comes in various colors too. Cost-wise, it’s generally a bit more expensive than plastic spiral due to the material and the binding process. It’s a very popular choice for planners and corporate notebooks.

- Sewn Lay-Flat Binding (sometimes Ota-bind or similar variations): This is a really neat option, especially for softcover books or notebooks where you want a premium feel and a flat opening. In a typical perfect-bound book, the cover is glued directly to the spine of the book block. With some sewn lay-flat techniques, the cover is only attached to the very first and last pages (or to the endpapers which are then attached to the book block), leaving the spine of the book block "free" from the cover’s spine. This allows the book to open much flatter without stressing the glue on the spine. It’s more expensive than standard perfect binding but offers a significant upgrade in usability.

- Section-Sewn Softcover: Even a standard softcover notebook can be made more durable and lay flatter if the internal pages are section-sewn before being glued into the cover (as opposed to individual loose leaves being glued in a perfect bind). This adds cost but improves the product’s longevity and how well it opens.

- Flexible Perfect Binding (with PUR): While not truly lay-flat like spiral or Wire-O, using a strong, flexible glue like PUR in perfect binding can allow the book to open wider and with less resistance than standard EVA hotmelt, without breaking the spine. It’s a compromise, but can be an improvement.

Each of these has its own cost implications and aesthetic. Wire-O is a direct competitor in terms of functionality. Sewn options move towards a more traditional book-like feel. When we discuss this with Michael for Panoffices products, it’s always a balance of how "flat" it needs to be versus the desired price point and overall product vibe.Conclusion

Choosing the right binding is a key cost decision for wholesale stationery. Balance page count, volume, desired aesthetic, and functionality to find the most profitable and appealing option.