Sourcing printing from China but worried about quality mismatches? It’s a common fear that can cost you big. Understanding standards is key to avoiding nasty surprises.

Global buyers should know that while China has its own "GB" standards, many export-focused printers also adhere to international norms like ISO, and it’s crucial to specify your exact quality requirements.

Navigating the world of international manufacturing, especially printing, can feel like a maze. I’ve had countless chats with buyers, like my good friend Michael in Germany who sources high-end stationery, and a recurring theme is always: "How do I ensure the quality from China matches my expectations?" It’s a totally valid question! The good news is, China’s printing industry has come a long way. They’re capable of producing world-class quality, but, as with sourcing from anywhere, you need to do your homework and be super clear about your standards. Let’s unpack what you, as a global buyer, really need to keep in mind.

Are Chinese Printing Standards Radically Different from International Ones?

Worried that "Made in China" means a completely alien set of printing rules? This uncertainty can make you hesitant to source, potentially missing out on great opportunities.

Chinese printing primarily uses national GB (Guobiao) standards, but export-oriented factories often adopt ISO standards and specific client requirements for quality, materials, and processes, ensuring global compatibility.

Okay, let’s tackle this head-on. When I first started working with Chinese manufacturers years ago for Panoffices, this was one of my big questions too! The short answer is: yes, China has its own set of national standards, known as "GB" (Guobiao) standards. These cover a vast range of products and processes, including printing. However, the printing industry in China, especially the part that serves international clients like Michael, is incredibly adaptive and export-focused.

What does this mean for you?

It means that while GB standards provide a baseline within China, reputable printing houses that work with global brands are also very familiar with, and often certified to, international standards like ISO (International Organization for Standardization). For example, ISO 12647 provides guidance on process control for the production of half-tone colour separations, proofs and production prints.

Here’s how we at Panoffices navigate this:

- We Don’t Assume: We never just assume a factory knows what "good quality" means to a European or North American market. We are specific.

- Contractual Clarity: Your requirements, whether they are specific ISO numbers, Pantone color codes, paper grammage, or binding types, MUST be clearly stated in your purchase order and manufacturing agreement.

- Focus on the Output: While it’s good to be aware of GB standards, what matters most to Michael isn’t whether the factory only follows GB, but whether the final printed Panoffices notebook or planner meets his brand’s specific quality criteria, which are often aligned with or exceed general international norms.

Think of it this way: a top chef in China can cook amazing traditional Chinese food using local techniques, but they can also prepare a perfect French cassoulet if given the right recipe and ingredients. It’s about capability and clear instructions. Many Chinese printers are like those versatile chefs! So, the crucial part isn’t so much a radical difference in potential, but the importance of your specifications guiding their process.What Key Quality Certifications Should I Look For in Chinese Printers?

Feeling lost in a sea of acronyms and certifications? Choosing a printer without knowing what these mean is like navigating without a map – you might get seriously lost.

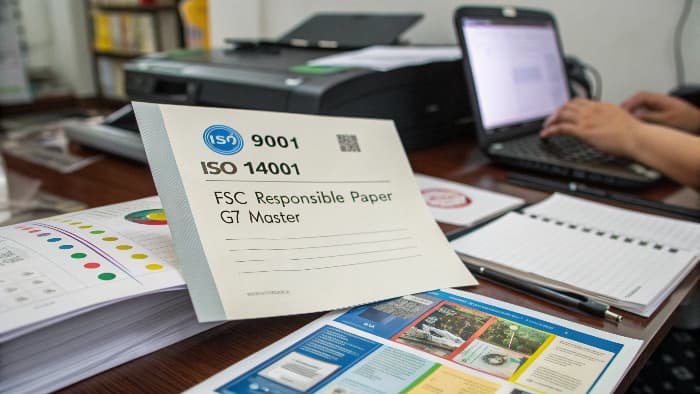

Look for ISO 9001 (quality management), ISO 14001 (environmental management), FSC (responsible paper sourcing), and potentially specialized certifications like G7 Master for color consistency when selecting Chinese printers.

This is a super practical question, and something I always guide Michael on when we’re evaluating new potential printing partners for Panoffices. Certifications aren’t just fancy badges; they often indicate a printer’s commitment to certain processes and standards. They can give you a degree of confidence, though they should always be backed up by your own vetting and sample reviews.

So, what are some of the big ones to keep an eye out for?

- ISO 9001: This is probably the most well-known quality management system standard globally. It means the printer has established processes for ensuring consistent quality and is committed to continuous improvement. It doesn’t guarantee every single print job will be perfect, but it shows they have a system in place to try and achieve that and to correct issues when they arise.

- ISO 14001: This one is all about environmental management. If sustainability is important to your brand (and it is for Panoffices, and increasingly for Michael’s customers), this certification shows the printer is actively managing their environmental impact, like waste reduction and pollution control.

- FSC (Forest Stewardship Council): This is crucial if you’re using paper products and want to ensure the paper comes from responsibly managed forests. For Panoffices’ eco-friendly stationery lines, FSC certification is a non-negotiable for our paper suppliers and printers handling that paper. It provides a chain of custody for the material.

-

G7 Master Qualification (or similar color management certifications like Fogra PSO): This is more specialized but incredibly important for brands where color accuracy is paramount. G7 is a methodology designed to ensure a similar visual appearance across multiple printing devices and processes. If Michael needs his brand’s signature blue to be exactly the same on his notebooks, brochures, and packaging, a G7 Master printer is more likely to achieve that.

Here’s a quick table to break it down:Certification Focus Area Why it Matters to a Buyer like Michael ISO 9001 Quality Management Systems Indicates consistent processes, commitment to quality, fewer surprises. ISO 14001 Environmental Management Shows commitment to sustainability, reduced environmental footprint. FSC Responsible Forestry Ensures paper is sourced from sustainable, well-managed forests. G7 Master Color Management Higher likelihood of accurate and consistent color reproduction. Remember, while certifications are good indicators, they are part of a bigger picture. You still need to review samples, communicate clearly, and perhaps even audit a factory. But looking for these can certainly help you shortlist potential partners. I always tell Michael, "Certifications are like a good CV; they get them an interview, but the ‘job’ (your order) depends on their actual performance!"

How Can I Ensure Color Consistency When Printing in China?

Frustrated by color variations in your print orders from China? Inconsistent colors can cheapen your brand and lead to rejected shipments. This is a common, costly headache.

Ensure color consistency by providing exact Pantone (PMS) or CMYK references, demanding physical proofs on actual stock, specifying lighting conditions for review, and maintaining open communication with your printer.

Oh, color consistency! If there’s one thing that can keep a product manager like Michael up at night, it’s the fear of his brand’s signature green looking more like a murky swamp color on 10,000 notebooks. This is, without a doubt, one of an area where you need to be extra vigilant and super clear with any printer, anywhere in the world, but especially when managing things remotely with China.

At Panoffices, we’ve developed a pretty robust system for this because, let’s face it, "that perfect shade of blue" can be very subjective! Here’s what we do:

- Speak the Same Language (of Color):

- Pantone Matching System (PMS): For spot colors (solid, specific brand colors), PMS codes are king. We don’t just say "dark blue"; we specify "Pantone 286 C". The "C" for coated or "U" for uncoated stock is also critical!

- CMYK Values: For full-color images or process printing, we provide precise CMYK (Cyan, Magenta, Yellow, Black) breakdowns.

- Digital Color Targets: Sometimes, for very specific digital prints, we might even provide L*a*b* color values.

- Proofing, Proofing, Proofing! I can’t stress this enough.

- Digital Proofs (Soft Proofs): These are PDFs. Good for checking layout, typos, and getting a general idea of color. But computer screens vary wildly, so never, ever rely on a digital proof for final color approval.

- Physical Proofs (Hard Proofs): This is where the rubber meets the road. We insist on proofs printed on the actual paper stock that will be used for the final job, using the actual printing method (e.g., offset, digital). Michael always gets these couriered to Germany for his sign-off. Yes, it adds a bit of time and cost, but it’s saved us from disasters many times.

- Drawdown Samples: For specific ink colors, a drawdown is a sample of the ink applied to the specific substrate.

- Standardized Viewing Conditions: Colors look different under different light sources (daylight, office fluorescent, showroom spotlights). We specify viewing conditions, often using a D50 or D65 standard illuminant in a light booth, so both we and the factory are looking at the proofs under the same light.

- On-Press Checks (If Possible/Necessary): For really critical, large-run jobs, having someone (either your own staff or a trusted third-party inspector) at the factory during the initial press run can be invaluable. They can approve the first sheets off the press before the full run commences. This was a game-changer for one of Panoffices’ biggest clients when they launched a new packaging range; we caught a slight deviation early and corrected it on the spot.

It’s a meticulous process, sure, but it’s the only way to get that peace of mind. The cost of a reprint or a rejected order due to bad color far outweighs the investment in proper proofing and clear communication.What About Environmental and Ethical Standards in Chinese Printing?

Concerned about the environmental or social impact of your printing? Sourcing without considering these can damage your brand’s reputation and go against your company’s values.

Many Chinese printers now meet international environmental (ISO 14001, FSC) and ethical (BSCI, Sedex) standards. Buyers should verify these certifications and conduct their own due diligence regarding sustainable practices.

This is a huge topic, and rightly so. In today’s world, consumers and therefore brands like Michael’s, are increasingly conscious of where and how their products are made. It’s not just about cost and print quality anymore; it’s also about the planet and the people involved in the production. So, when we at Panoffices look for printing partners in China, environmental and ethical considerations are high on our checklist.

The landscape in China has been changing. While there are still challenges, there’s a growing number of printing facilities that are genuinely committed to better practices. Here’s what to look for and how to approach it:

- Environmental Certifications (again!):

- ISO 14001: As mentioned before, this shows a system for managing environmental impact.

- FSC (Forest Stewardship Council): Essential for ensuring paper comes from responsible sources. This is a big one for Panoffices’ "Smart Stationery, Better Work" slogan – we want our smart products to be made smartly too!

- Inks and Chemicals: Ask about the types of inks used (e.g., soy-based or vegetable-based inks vs. petroleum-based) and their policies on managing chemical waste.

- Social Compliance / Ethical Standards:

- BSCI (Business Social Compliance Initiative): This is a widely recognized European initiative that aims to improve working conditions in global supply chains. Member companies commit to a code of conduct and have their suppliers audited.

- Sedex (Supplier Ethical Data Exchange): This is a global platform where suppliers can share ethical audit reports (often SMETA audits – Sedex Members Ethical Trade Audit). It covers labor standards, health & safety, environment, and business ethics.

- SA8000: Another standard for decent work, covering areas like child labor, forced labor, health and safety, and wages.

Our Approach at Panoffices:- Ask Questions: We directly ask potential suppliers about their certifications and practices.

- Request Documentation: We ask to see copies of valid certificates. And – pro tip – always check the validity period and scope of the certification!

- Factory Visits/Audits: When possible, visiting a factory (or having a trusted third-party do it) gives you insights that documents alone can’t. You can observe conditions, see waste management in practice, and talk to management.

- Building Relationships: Long-term partnerships with suppliers often lead to better transparency and a willingness to improve. We’ve worked with some printing partners for years, and we’ve seen them evolve and invest in better practices, sometimes with our encouragement. Michael really appreciates this long-term view; it builds trust.

It’s an ongoing process, not a one-time check. But by prioritizing these standards, you’re not only protecting your brand but also contributing to a more responsible global printing industry. It’s definitely worth the effort.Conclusion

Navigating Chinese printing standards requires clear communication, specifying international norms like ISO, and verifying certifications. This ensures global buyers receive quality products that meet their precise expectations.