Struggling with books that don’t last or lay flat? It’s a real letdown. Explore how special binding elevates books, making them durable and a joy to use.

Specialty bookbinding masterfully combines age-old craftsmanship with cutting-edge technology. It offers a diverse array of methods, from the hand-sewn Coptic stitch to robust PUR adhesive, significantly enhancing a book’s longevity and visual appeal. This is crucial for creating truly quality stationery products.

As a stationery enthusiast and supplier at Panoffices, I’ve always been captivated by the art and science of how books are constructed. It’s about so much more than just the cover design or the paper quality; the binding is absolutely fundamental. It dictates how durable a book will be, how easily it opens (or doesn’t!), and the overall tactile experience it offers. So, I thought we could dive into this world together. You know, Michael, understanding these techniques can be a real game-changer when you’re sourcing new products or developing an innovative stationery line. It’s not just about holding pages together; it’s a craft that adds immense value. Let’s get into it, shall we?

What Was the Old Book Binding Method, and Why Does It Still Inspire Us?

Ever marveled at ancient tomes that have survived centuries? Old methods were incredibly laborious but created true masterpieces. Let’s explore the enduring legacy of traditional bookbinding that still wows us.

Ancient bookbinding methods, such as the elegant Coptic stitch and classic traditional case binding, relied heavily on hand-sewing sections and using natural, resilient materials. These techniques ensured remarkable durability and a distinct, handcrafted aesthetic that continues to influence even modern luxury editions today.

When I think about old bookbinding methods, I get a bit romantic, I admit! But it’s for good reason. Take the Coptic stitch, for example. This technique, originating in Egypt, allowed books to open completely flat – a feature we still prize today, especially for journals and sketchbooks. The spine was often left exposed, showcasing the intricate stitching as a design element. Then there’s traditional case binding, the kind you see on sturdy, library-style hardcovers. Pages were meticulously sewn into sections, or signatures, which were then securely attached to rigid cover boards. We’re talking serious craftsmanship here.

The materials were also key: real leather, vellum (animal skin parchment), rich linen threads, and sometimes even wooden boards for covers. These weren’t just chosen for looks; they were chosen for their incredible longevity. I remember seeing a medieval manuscript in a museum once, its binding still holding strong after hundreds of years. It really drove home how these artisans were building items to last lifetimes. This profound respect for materials and process is something we at Panoffices deeply admire and try to echo, even when we’re working with modern, scalable manufacturing. It’s that dedication to creating something of lasting value that still inspires. For product developers like you, Michael, understanding this heritage can spark ideas for premium lines that tell a story of quality and timeless design. It’s not just a book; it’s an experience.

So, What Are the Different Types of Book Binding Techniques Available Today?

Feeling lost in a sea of binding jargon like "PUR" or "Smyth sewn"? Choosing the right binding for your project can feel overwhelming. Let’s demystify the common types and their best uses.

Bookbinding techniques today are incredibly varied. They range from robust sewn methods like Smyth sewn, prized for ultimate durability, to efficient adhesive bindings like perfect binding or PUR, often chosen for cost-effectiveness. Each method is tailored to different needs, whether it’s lay-flat convenience, brute strength, or pure aesthetics.

Alright, let’s break down the main players in the binding world. It can seem complex, but it’s actually quite logical once you get the hang of it. I often think of them in a few broad categories.

First, you have Sewn Bindings. The star here is usually Smyth sewn. This is where those folded sections of pages (signatures) are literally stitched together with thread, and then the whole block is attached to the cover. This method is fantastic for durability and allows books, especially hardcovers and high-quality softcovers, to lay relatively flat. It’s a sign of quality, no doubt.

Then there are Adhesive Bindings, often called "perfect binding." This is super common for paperbacks and many journals. The edges of the pages are glued directly to the spine of the cover. The older EVA hotmelt glues could sometimes be a bit stiff or brittle, but modern PUR (Polyurethane Reactive) adhesive has revolutionized this, offering much greater strength and flexibility.

For simpler, thinner items, there’s Saddle Stitching. If you’ve ever seen a booklet or a magazine held together by staples along the fold, that’s saddle stitching. It’s quick, economical, but generally best for lower page counts.

And lastly, Mechanical Bindings. This category includes popular choices like spiral binding (with a plastic or metal coil), Wire-O binding (with double-loop wire), and comb binding. These are champions of lay-flat functionality, perfect for notebooks, planners, and cookbooks where you need the pages to stay open easily. When I’m talking with clients like you, Michael, we often start with, "How will this book be used?" because that really helps narrow down the best binding approach.

How Are Modern Books Usually Bound, and What Innovations Should We Look Out For?

Think bookbinding technology is gathering dust in a forgotten workshop? Think again! Modern methods bring speed, innovative materials, and surprising strength. Discover the cool innovations revolutionizing book production today.

Modern books are typically bound using highly automated processes for perfect binding, case binding, or advanced PUR binding. Key innovations include significantly stronger adhesives like PUR for superior lay-flat capabilities and seamless integration with digital printing for customized, short-run productions.

The world of bookbinding hasn’t stood still, that’s for sure! While the charm of traditional methods is undeniable, modern innovations have brought some incredible advancements, especially in terms of efficiency, durability, and new possibilities. One of the biggest game-changers I’ve seen in my years at Panoffices is the widespread adoption of PUR adhesive. Seriously, this stuff is amazing. Compared to older EVA hotmelt glues used in perfect binding, PUR is incredibly strong and flexible. This means softcover books can lay much flatter without the spine cracking, and it adheres brilliantly to all sorts of paper stocks, including glossy or coated papers that used to be tricky. For items like daily planners or travel journals that get a lot of handling, PUR is a fantastic choice for longevity.

Automation has also transformed case binding (hardcover production). While there’s still a place for hand-finishing on ultra-luxury items, modern automated lines can produce high-quality hardcovers with amazing consistency and speed. This is crucial for larger orders where maintaining uniform quality is key, something you’d appreciate, Michael, when looking at scaling a successful product. Then there’s the impact of digital printing. The ability to print short, highly customized runs efficiently means binding solutions have had to adapt. We’re seeing more demand for binding that can handle these smaller, often personalized, batches without the massive setup costs of traditional large-scale binding. It means brands can be more agile, test new designs, or offer personalized products more easily. It’s a really dynamic area, and these innovations are constantly pushing what we can achieve in terms of quality, functionality, and even sustainability in book manufacturing.

For Practical Sourcing, What Key Binding Categories Should a Buyer Focus On?

Feeling swamped by all the binding choices out there? Need to make smart, effective decisions for your company’s product line? Let’s zero in on the key binding categories for efficient sourcing.

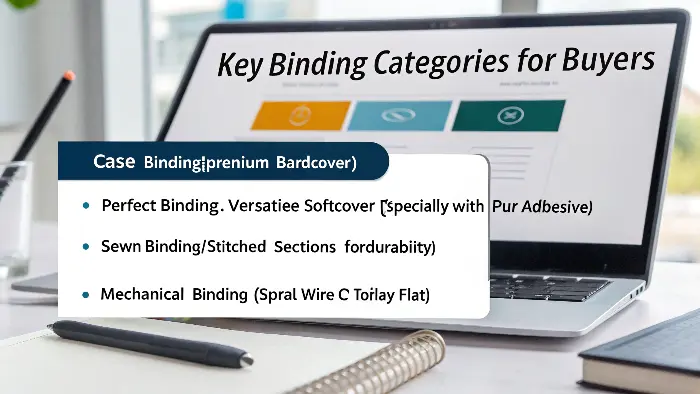

Key binding categories for buyers like you, Michael, include: 1. Case Binding (premium hardcover), 2. Perfect Binding (versatile softcover, especially with PUR), 3. Sewn Binding (stitched sections for durability), and 4. Mechanical Binding (spiral, Wire-O for lay-flat). Understanding these simplifies product development.

Okay, Michael, when you’re in the thick of product development or sourcing, it’s super helpful to mentally bucket binding types into a few core categories. This really helps streamline the decision-making process. First up, you’ve got Case Binding. This is your go-to for those premium, hardcover items – think deluxe journals, elegant photo books, or special commemorative editions. It just shouts "quality" and offers fantastic opportunities for beautiful finishes like debossing, foil stamping, or custom printed wraps. It’s about creating that high perceived value.

Then there’s Perfect Binding, the workhorse for many softcover books and notebooks. It’s versatile and generally cost-effective for larger runs. My big tip here? Always push for PUR adhesive if you can. The improvement in spine strength and lay-flat quality compared to older EVA glues is just night and day, especially for products that will see daily use. For a definite step up in quality and durability, especially for notebooks and journals that need to last and open nicely, look at Sewn Signatures (like Smyth sewn). This is where pages are stitched together in sections before being bound. It’s a true hallmark of robust construction, whether for a high-end softcover or a hardcover. And finally, for products where ultimate lay-flat functionality is critical – like planners, workbooks, or cookbooks – Mechanical Bindings such as Wire-O, spiral, or coil are unbeatable. They allow the book to open a full 360 degrees! Each of these categories – case, perfect, sewn, and mechanical – has its own sweet spot in terms of cost, aesthetic, and function. Having this framework in mind when you’re briefing us at Panoffices for a new stationery line makes everything so much smoother. We can quickly align on the best approach for your vision! 🔥

Conclusion

Ultimately, understanding bookbinding techniques empowers you to choose better, create more durable, and design more user-friendly stationery. Select wisely for products that truly stand out!