Ever held a beautifully crafted Bible and wondered about the journey it took to become such a cherished item? It’s easy to overlook the incredible detail and care that goes into producing a book meant to last generations. The wrong choices can lead to a Bible that falls apart too soon or just doesn’t feel right in your hands.

Producing a Bible involves a meticulous selection of materials like specialized thin paper and durable cover options (leather, faux leather, or cloth). Binding is crucial, with Smyth-sewn methods offering longevity. Finishing touches such as gilded edges, ribbon markers, and embossing not only add beauty but also protect the Bible, making it a treasured possession for years of study and reflection.

The process of creating a Bible is fascinating, really. It’s a blend of tradition, craftsmanship, and modern technology. I remember when Panoffices was approached by a client looking to produce a special edition commemorative Bible; it was a learning curve, but so rewarding! We had to dive deep into what makes a Bible not just a book, but an heirloom. It’s not just about printing words on a page; it’s about creating something that can withstand daily use, feel good to hold, and look reverent. So, let’s explore the key elements – the materials, the binding, and those all-important finishing touches – that transform simple components into a sacred text.

What Are the Most Cherished Materials for Crafting a Bible?

Thinking about what makes a Bible feel special? Often, it starts with the very materials it’s made from. You want paper that’s thin yet opaque, and a cover that’s both beautiful and durable. Choosing subpar materials can really detract from the experience of using a Bible daily.

The most cherished materials for Bible production include high-quality, thin "Bible paper" (often with good opacity to prevent show-through), and durable cover materials like genuine leather (calfskin, goatskin), premium imitation leather, or sturdy book cloth. These choices ensure longevity and a pleasant tactile experience for the reader.

When we started looking into Bible production for that client I mentioned, the paper was one of the first big discussions. It’s a real balancing act! You need paper that’s thin enough to keep the Bible from being overly bulky, especially since Bibles contain so much text. But, it also needs to be strong enough to withstand page-turning and opaque enough so the text from the other side doesn’t bleed through too much. And the cover – oh, the cover! That’s the first thing people see and touch. It sets the tone. Let’s delve a bit deeper into these crucial components.

Diving Deeper into Bible Materials

The choice of materials is fundamental to a Bible’s quality and longevity. It’s not just about looks; it’s about function and feel.

-

Paper: This is a world unto itself!

- Bible Paper (India Paper): This is the classic choice. It’s a thin, lightweight, yet surprisingly strong and opaque paper. The goal is to minimize "ghosting" (seeing text from the reverse side) and "bleed-through" (ink soaking through). I learned that the gsm (grams per square meter) for Bible paper is typically quite low, maybe 28-40 gsm, compared to standard book paper which might be 80-100 gsm. It’s amazing how they achieve that!

- Opacity and Whiteness: These are key characteristics. Higher opacity is better. The shade of white can also vary, from bright white to a softer, creamy off-white, which some find easier on the eyes for extended reading. We actually got samples of different paper types, and holding them up to the light to check for ghosting was a critical step.

- Acid-Free: For longevity, ensuring the paper is acid-free is vital to prevent yellowing and degradation over time.

-

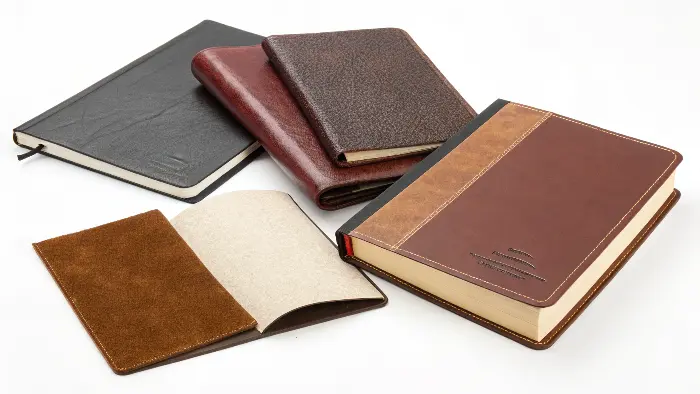

Cover Materials: This is where you can really define the Bible’s character.

- Genuine Leather: This is the premium option.

- Goatskin (Morocco leather): Highly prized for its softness, flexibility, and durability. It has a beautiful natural grain.

- Calfskin: Smooth, supple, and strong, offering a luxurious feel.

- Cowhide: Can be very durable, often used for more rugged Bibles.

- Imitation Leather (Faux Leather / Leatherette): Modern imitation leathers can be very good quality, offering a similar look and feel to genuine leather but at a lower cost. Polyurethane (PU) leather is a common choice. We found some PU options that were surprisingly soft and durable.

- Bonded Leather: Made from leather fibers bonded together with an adhesive. It’s more affordable than genuine leather but generally less durable.

- Cloth (Book Cloth): Hardback Bibles often use cloth over board (often linen or cotton). It’s durable and can be beautifully printed or stamped.

- Genuine Leather: This is the premium option.

The choice really depends on the target audience, the desired price point, and the intended use. For a gift Bible, genuine leather is often preferred. For a pew Bible, a sturdy cloth or durable imitation leather might be more practical.

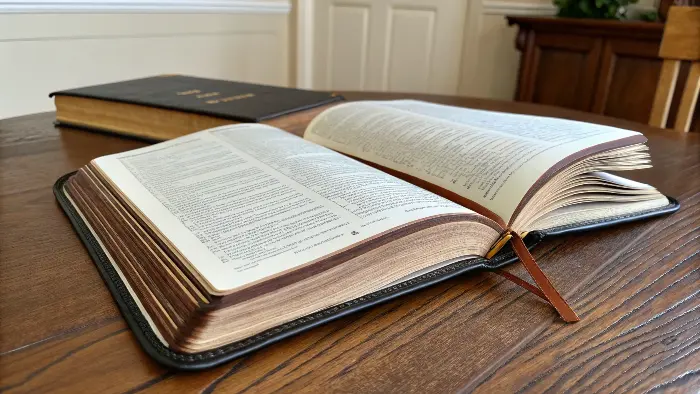

How Is a Bible Bound to Withstand Years of Devotion and Study?

Ever had a book where the pages start falling out after a bit of use? That’s the last thing you want for a Bible, a book that’s meant to be read, re-read, and cherished for years, maybe even decades. The binding is absolutely critical.

To withstand years of devotion, Bibles are ideally Smyth-sewn, a method where pages are stitched together in sections (signatures) before being bound to the cover. This is highly durable and allows the Bible to lay flatter. Edge-lined binding, often used with premium leather covers, offers superior flexibility and strength. While perfect binding (glued spine) is more economical, it’s less durable for a book intended for long-term, frequent use.

The binding is like the skeleton of the Bible – it holds everything together. I’ve seen Bibles that were clearly well-loved but still intact after decades, and that’s usually down to a quality binding. When we were specifying the production for our client’s Bible, the binding method was a non-negotiable point for durability. It’s tempting to cut costs here, but for a Bible, it’s just not worth it in the long run. You want something that can handle being opened and closed thousands of times. Let’s look at the main methods.

Diving Deeper into Bible Binding Techniques

The binding method significantly impacts a Bible’s durability, how it lays open, and its overall lifespan. Here’s a breakdown:

-

Smyth-Sewn Binding:

- Process: The pages are printed on large sheets, then folded into sections called "signatures" (typically 16 or 32 pages). Each signature is then sewn together through the fold. All the sewn signatures are then combined to form the "book block," which is subsequently attached to the cover.

- Pros: This is the gold standard for durability. Pages are physically stitched, making them very secure. Smyth-sewn Bibles also tend to lay flatter when open, which is a huge plus for study. I always look for this in a quality Bible.

- Cons: It’s more expensive and time-consuming than other methods.

-

Edge-Lined Binding:

- Process: This is a premium technique often used with high-quality leather covers, especially goatskin. The leather cover is lined with another material (often a synthetic liner or another piece of leather) and the book block is glued directly to this lining, with the cover’s edges wrapped around the book block. The spine of the book block itself is usually Smyth-sewn.

- Pros: Offers incredible flexibility and durability. The cover becomes an integral part of the book’s structure, allowing it to open very flat and withstand a lot of flexing without stress on the spine. These Bibles feel amazing in hand.

- Cons: This is a very specialized and expensive method, usually reserved for top-tier Bibles.

-

Perfect Binding (Glued Binding):

- Process: The edges of the collated pages are roughened, and then adhesive is applied to create a spine. The cover is then glued onto this spine. This is common for paperback books.

- Pros: It’s much more cost-effective and faster to produce than sewn bindings.

- Cons: Significantly less durable for a book like a Bible that gets frequent, long-term use. Pages are more likely to come loose over time, especially if the Bible is flexed open wide repeatedly. While some modern adhesives are very strong, it generally doesn’t compare to a sewn binding for longevity. We generally advise against this for Bibles intended for serious, long-term use, unless budget is an extreme constraint.

-

Case Binding (Hardcover):

- Process: This refers more to the cover type. The book block (which should ideally be Smyth-sewn for a Bible) is attached to rigid cover boards that are typically covered with cloth, imitation leather, or sometimes paper.

- Pros: Offers excellent protection to the pages.

- Cons: Can be a bit stiff initially, though a well-made case-bound Bible with a Smyth-sewn block will still lay reasonably flat.

For a Bible meant to last, Smyth-sewn is really the way to go for the book block, whether it’s a flexible leather cover or a hardcover.

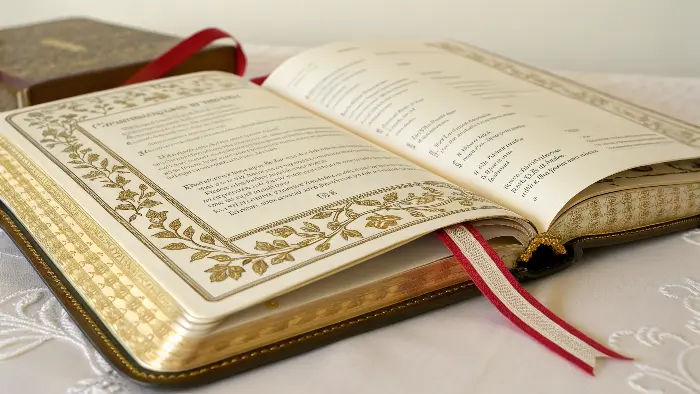

What Finishing Options Add That Special Touch of Reverence and Protection to a Bible?

Beyond the paper and binding, it’s the finishing touches that often elevate a Bible from a simple book to a treasured object. These details can add beauty, a sense of reverence, and even practical protection. But what are these options, and what do they really do?

Finishing options like foil stamping or embossing on the cover, gilded page edges (gold, silver, or art-gilt), ribbon markers, and head and tail bands enhance a Bible’s aesthetic appeal and tactile quality. Gilding also helps protect page edges from dust and moisture, while ribbons aid navigation. These details contribute significantly to the Bible’s overall perceived value and user experience.

I find that these finishing touches are where the personality of the Bible really comes through. It’s like the accessories that complete an outfit. When we were designing that commemorative Bible, we spent a good amount of time discussing these details – the color of the gilding, how many ribbon markers, the style of the embossing. These aren’t just frivolous additions; they serve a purpose, whether it’s practical or purely to enhance the devotional experience. It’s these little things that make you go "wow" when you pick it up.

Diving Deeper into Bible Finishing Touches

These details might seem small, but they make a big difference in the final product, adding both beauty and functionality.

-

Cover Decoration:

- Foil Stamping: Applying metallic foil (gold, silver, copper, or even colors) to the cover using heat and pressure. Commonly used for titles, spine details, and decorative elements. It adds a touch of elegance. We did a beautiful gold foil stamp on the spine of the Bibles we produced.

- Embossing/Debossing: Creating a raised (embossed) or indented (debossed) design on the cover material. This adds a tactile dimension and can be very subtle or quite prominent. "Blind embossing" (no foil) can look very sophisticated.

- Perimeter Stitching: For leather or imitation leather covers, a stitched perimeter can add a look of craftsmanship and also reinforce the edges.

-

Page Edge Treatment:

- Gilding: Applying a thin layer of gold, silver, or other metallic leaf to the three outer edges of the book block. It looks beautiful and also helps to protect the page edges from dust and moisture, and can even help prevent pages from sticking together in humid conditions.

- Art Gilding (Red Under Gold): This is a premium finish where the page edges are first colored (often red) and then gilded. When the Bible is open, you see the color; when closed, you see the gold. It’s a classic, beautiful look. I was really impressed when I first saw an art-gilt Bible – it’s a subtle but stunning detail.

- Sprayed Edges: Page edges can also be sprayed with a color, which is more economical than gilding.

-

Other Functional and Aesthetic Details:

- Ribbon Markers: One or more ribbons bound into the spine to help mark pages. The number and color of ribbons can be customized. Essential for quick referencing!

- Head and Tail Bands: Small decorative bands of colored cloth (often silk or cotton) glued at the top (head) and bottom (tail) of the spine of the book block, visible when the book is closed. They add a finished look and a bit of structural support.

- Thumb Indexing: C-shaped cuts on the fore-edge of the pages, labeled with the books of the Bible, for quick navigation. More functional than aesthetic, but a popular option for some.

- Presentation Pages: Specially designed pages at the front for inscriptions, dedications, or family records.

Each of these elements contributes to the overall experience of owning and using a Bible. They reflect care in craftsmanship and an understanding of the Bible’s significance to the user.

Conclusion

Creating a Bible is a true art, blending quality materials, durable binding, and thoughtful finishing touches. From the choice of paper and leather to Smyth-sewn spines and elegant gilding, every detail matters. It’s about crafting a book that’s not just read, but cherished for a lifetime of spiritual engagement.