Books falling apart too soon? It’s frustrating! Discover how binding evolved, ensuring your stationery products are built to last and impress.

Bookbinding has journeyed from ancient hand-sewn codices to sophisticated automated production. This evolution, driven by technology and changing needs, directly impacts the durability and style of modern books and stationery, a key consideration for any product developer.

I’ve always been fascinated by how things are made, and books are no exception. As someone deep in the world of stationery with Panoffices, understanding this journey from painstaking craft to high-tech production is pretty amazing. It really puts into perspective the quality and design choices we make today. Michael, I think you’ll find this evolution quite insightful for your work in developing new stationery lines. It’s a story of innovation, art, and the enduring desire to preserve and share knowledge. So, let’s explore this history, shall we?

What Is the Real Story Behind How Book Binding Began?

Curious how we got from ancient scrolls to the books on your shelf? It’s a long, fascinating journey. Let’s uncover the origins of bookbinding together.

Bookbinding history starts with Egyptian papyrus scrolls, evolving to the Roman codex—folded parchment between wooden boards. Medieval monks then elevated it to an art, hand-sewing and embellishing religious texts, laying the groundwork for the books we know.

The story of bookbinding is really the story of how we’ve tried to protect and share knowledge. It’s a pretty cool evolution when you think about it.

From Papyrus Scrolls to Early Books

Way back, the Egyptians used papyrus scrolls. Imagine long sheets of plant material, written on, then rolled up and often tied with a string. They even had special containers to keep them safe. This was one of the earliest ways to store big chunks of information. But, as you can guess, unrolling a giant scroll to find one specific bit of text wasn’t exactly user-friendly!

The Roman Codex: A Leap in Usability

Then came the Romans, and they were quite clever. They developed what we call the "codex." This was a game-changer. They took materials like parchment (made from animal skins), folded the sheets, and then bound them between wooden boards. This, Michael, was the true ancestor of the modern book. Suddenly, information was much more portable and way easier to flip through. No more endless unrolling! This format really stuck.

Monastic Craftsmanship: Books as Treasures

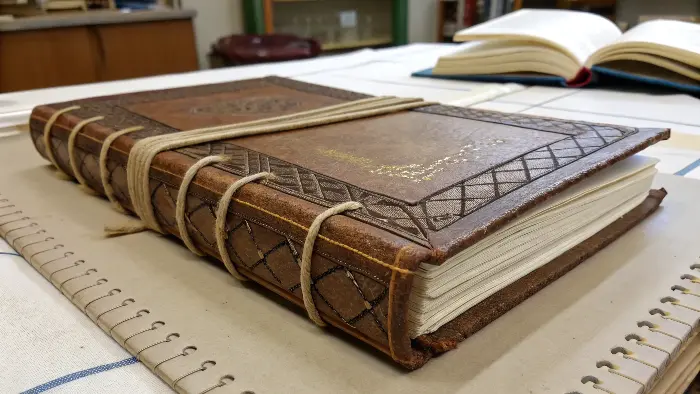

Fast forward to the Middle Ages, and bookbinding became a real art form, especially in monasteries. Monks weren’t just copying texts by hand; they were meticulously binding them. They used strong leather for covers, sometimes even wood, and the books were often decorated with precious metals or jewels. These weren’t just books; they were treasures, reflecting how valuable the texts inside were. They really mastered hand-sewing techniques.

The Printing Press Revolution

And then, BAM! The 15th century brought Johannes Gutenberg and the printing press. This changed everything. Suddenly, books could be made in large numbers. This mass production meant binding methods had to get faster and more standardized. While hand-sewing was still around for high-end stuff, people started looking for quicker ways, like using glues, to keep up with the demand. This was a huge turning point, leading us towards the methods we see today.

What Made Old Book Binding Methods So Special and Enduring?

Ever wonder why some old books have lasted for centuries? The secret lies in meticulous handcrafting. Let’s look at the details of these traditional techniques.

Old bookbinding methods centered on hand-sewing sections (signatures) onto supports like cords or tapes, often using durable materials like leather or vellum for covers. This labor-intensive process created exceptionally strong and beautiful books designed to endure.

When I handle an old, traditionally bound book, I really get a sense of the care that went into it. It’s not just about looking old; it’s about the incredible craftsmanship that made them last. There are a few key things that made these methods so special.

The Art of Hand-Sewing Signatures

The absolute heart of old bookbinding was hand-sewing. Book pages were printed on large sheets, then folded into sections called "signatures." These signatures weren’t just glued together; they were carefully sewn, often onto supports like strong linen cords or leather thongs that ran across the spine. This stitching created a super strong, flexible book block. It’s why you can open an old book, and it lays relatively flat without the pages falling out. It was painstaking work, for sure, but the result was a book built like a tank!

Natural Materials: The Secret to Longevity

The materials they used were also top-notch for durability. We’re talking real leather – often calfskin or goatskin – or vellum for the covers. These materials are incredibly tough and can withstand a lot of wear and tear over centuries. The threads were usually linen, known for its strength, and even the boards for the covers were often made of dense, seasoned wood. These natural materials aged beautifully and contributed significantly to the book’s lifespan. It wasn’t about finding the cheapest option; it was about finding the best option for a long-lasting product.

More Than Just Covers: Decorative Traditions

And let’s not forget, these books were often stunning works of art. Binders didn’t just make them strong; they made them beautiful. Covers were decorated with intricate tooled designs pressed into the leather, sometimes highlighted with gold leaf. They used metal clasps to keep the books tightly closed, protecting the pages. Some books, especially important religious texts, were adorned with gemstones or ivory carvings. This wasn’t just decoration; it signaled the importance and value of the content within.

Early Tools: The Binding Frame’s Role

To help with the precision and consistency of the sewing, binders developed tools like the "binding frame" or "sewing frame." This wooden contraption held the cords or tapes taut, allowing the binder to sew the signatures to them accurately and efficiently—well, efficient for handwork! It helped ensure the spine was straight and the tension was even. It was a simple but ingenious piece of technology for its time, improving both the quality and speed of the hand-sewing process. It’s fascinating to see how even early craftspeople looked for ways to refine their techniques.

How Exactly Are Books Put Together in Today’s Factories?

Seen books churned out in modern factories? It’s a marvel of technology. Let’s peek behind the curtain at how contemporary bookbinding gets the job done.

Modern books are primarily bound using automated machinery for methods like perfect binding (with strong PUR adhesives), case binding (hardcovers), and various sewn bindings. Speed, consistency, and cost-effectiveness are key drivers in today’s production.

Stepping into a modern bindery is a whole different world compared to the quiet scriptoriums of the past. It’s all about precision machinery, automation, and, frankly, incredible speed. As a supplier, we at Panoffices work closely with facilities that use these modern methods to produce high-quality stationery.

The Rise of Automated Book Production

Automation is the king in modern bookbinding. From the moment printed sheets arrive, machines take over for many processes. They can fold the sheets into signatures, gather them in the correct order, and then feed them into the binding line. For example, in perfect binding (common for paperbacks and many journals), machines will mill the spine edge of the collated pages to create a rough surface, apply a hot adhesive, and then immediately press the cover onto it. The speed is astounding – thousands of books can be bound in an hour. This efficiency is what makes books so accessible today.

Perfecting Adhesives: The PUR Advantage

Speaking of adhesives, this is an area where there’s been huge progress. Older perfect binding often used EVA (Ethylene Vinyl Acetate) hot melt glues. They were okay, but could sometimes become brittle, leading to cracked spines or loose pages, especially in books that were opened wide frequently. The big innovation here is PUR (Polyurethane Reactive) adhesive. Michael, this stuff is a game-changer. PUR is incredibly strong and much more flexible than EVA. It creates a much more durable bind, allows books to lay flatter without breaking, and sticks really well to all sorts of paper, including coated and glossy stocks. For any stationery item like a journal or planner that’s going to see a lot of use, I always recommend looking into PUR.

Efficient Hardcovers: Modern Case Making

Even case binding, the method for making sturdy hardcovers, is highly automated now. Machines can create the "case" (the hard outer cover) by gluing cover material (like cloth or printed paper) onto stiff boards. Then, the sewn or glued book block is precisely attached to this case, often with an automated "casing-in" machine. While some luxury editions might still have hand-finishing, the bulk of hardcover production is done by machines that ensure consistency and speed.

Binding for the Digital Age: Customization and Short Runs

Another big driver in modern binding is the rise of digital printing. This allows for short runs, print-on-demand, and even personalized books. Binding technologies have had to adapt to this. We’re seeing more flexible binding lines that can switch between jobs quickly or handle smaller batches efficiently. This means brands like yours can be more agile, test new designs, or offer unique, customized stationery without committing to massive print runs. It’s all about smart production for smart stationery.

What Is Sewn Binding Actually Called, and Why Is It Still a Big Deal?

Heard "sewn binding" but unsure what it truly means for quality? This method is a gold standard. Let’s clarify its types and lasting importance.

Sewn binding, often called "Smyth sewn" for a common machine method, involves stitching through the folds of gathered sections (signatures). It’s prized for superior strength, flexibility, and allowing books to lay flatter, a hallmark of quality.

When we talk about quality bookbinding, especially for products meant to last or offer a premium feel, "sewn binding" inevitably comes up. It’s a term that signifies durability and a better user experience. But what exactly is it, and why is it still so valued, even with all the modern adhesive technologies?

Smyth Sewing: The Gold Standard Explained

Often, when people in the industry mention sewn binding, they’re referring to Smyth sewing. This isn’t a person’s name you need to remember for a test, but rather a type of industrial sewing machine that automates the process of stitching through the folds of the gathered signatures (those folded sections of pages). The threads interlock from one signature to the next, creating a very strong and flexible book block. If you look closely at the spine of a high-quality hardcover or a durable softcover novel, you can often see the tell-tale threads in the center of each signature. This method is widely considered the gold standard for creating books that need to withstand heavy use.

Beyond Smyth: Exploring Other Stitched Styles

While Smyth sewing is dominant for machine-sewn books, it’s good to remember that "sewn binding" is a broader category. There’s also section sewing, which is a general term for any method that sews through the sections. And for more artisanal or specialty items, you might even see a revival of hand-sewing techniques like the Coptic stitch, which allows a book to open completely flat and often leaves the spine beautifully exposed. For certain types of journals or sketchbooks, this can be a really attractive and functional feature. As a product developer, Michael, knowing these distinctions can help you specify exactly the kind of quality and finish you’re after.

The Tangible Benefits: Why Sewn Still Wins

So, why bother with sewing when modern adhesives like PUR are so good? Well, sewn bindings offer a few distinct advantages. First, durability. The physical stitching provides a mechanical lock that’s incredibly resistant to pages falling out. Second, flexibility and lay-flat quality. Sewn books, especially hardcovers, tend to open more easily and can lie flatter without stressing the spine as much as some perfect bound books. This is a huge plus for user experience – nobody likes wrestling with a book that wants to snap shut!

Balancing Cost and Quality with Sewn Binding

Of course, sewn binding is generally more expensive than adhesive binding because it involves more mechanical steps and sometimes slower production speeds. However, for products where longevity, a premium feel, and ease of use are paramount – think reference books, high-quality notebooks, or keepsake editions – the extra investment in sewn binding is often well worth it. It’s a clear signal of quality that customers, especially those who appreciate well-made stationery, will notice and value. It’s a conversation we often have at Panoffices: balancing the budget with the desired end-product quality.

Conclusion

The journey of bookbinding, from ancient scrolls to today’s automated marvels, truly reflects our dedication to preserving and sharing ideas. Understanding this evolution helps us make better choices for quality.