Finding a manufacturer for religious publications carries immense responsibility. You need absolute accuracy, high-quality materials that honor the text, and a partner who respects its significance. Choosing the wrong supplier can lead to costly errors, materials that fall apart, and a final product that fails your community. Let’s explore how to find a partner who truly understands this important work.

To find the right manufacturer, focus on specialists with proven experience in religious or high-stakes text printing. You must verify their quality control for accuracy, examine their material options for durability, and confirm their understanding of the cultural significance of your text. Ask for samples of similar projects and check their references thoroughly. This ensures your publication is produced with the care and precision it deserves, honoring both the content and the reader.

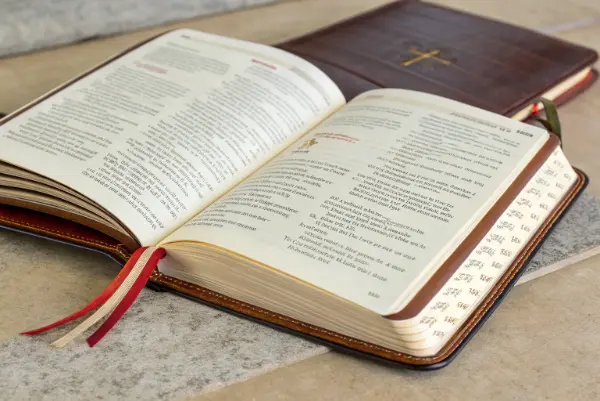

Successfully producing a religious text is about more than just printing words on a page. It’s about creating a physical object that can become a cherished part of someone’s spiritual life for years, or even decades. The right manufacturing partner understands this. They don’t just see a book; they see a Bible, a Quran, a prayer book, or a study guide that requires a higher level of care. This guide will walk you through finding that ideal partner.

What Key Qualities Define a Great Religious Publication Manufacturer?

You’re looking for more than just a printer; you need a dedicated craftsperson. The project’s success hinges on finding a company that values precision and quality as much as you do. A small mistake is not just a typo; it can be a critical error that undermines the text’s integrity. How do you spot a truly exceptional manufacturer in this specialized field?

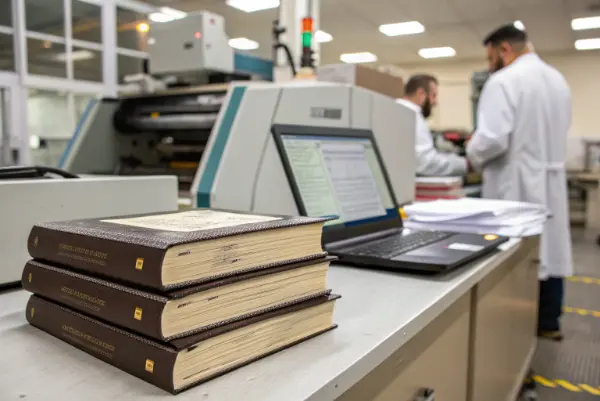

A great manufacturer for religious publications combines technical precision with a deep respect for the material. They demonstrate this through rigorous proofreading and quality control systems, expertise in durable materials like thin bible paper and smyth-sewn binding, and transparent communication. They should be able to provide samples that prove their ability to handle delicate details like gilding, debossing, and multi-language typesetting with flawless execution. Ultimately, they act as a partner, not just a supplier.

Finding a manufacturer with the right qualities is the foundation of your project. It’s not just about their machines or their prices. It’s about their mindset and their processes. When I first started sourcing complex projects, I created a checklist to evaluate potential partners. It helped me move beyond the sales pitch and look for tangible proof of their capabilities. A reliable partner welcomes this kind of detailed inquiry because they are proud of the quality they deliver. They understand that for these types of publications, there is no room for compromise.

Key Manufacturer Attributes

A top-tier manufacturer excels in three core areas: precision, material knowledge, and process integrity. Precision is non-negotiable. It means having multi-stage proofreading processes and zero tolerance for errors in text, pagination, or formatting. Material knowledge is about recommending the right paper, cover, and binding to ensure the book is both beautiful and durable enough for daily use. Process integrity means they handle the sacred text with respect and have ethical production standards.

Differentiating the Experts from the Amateurs

It’s crucial to know the signs of a professional versus an inexperienced supplier. Experts will ask detailed questions about your project, while amateurs will focus only on price. I remember one potential supplier who couldn’t explain the difference between bible paper weights. We ended that conversation quickly. An experienced partner, however, will guide you through the options and explain the benefits of each.

Here is a simple table to help you compare:

| Feature | Expert Manufacturer | Inexperienced Supplier |

|---|---|---|

| Consultation | Asks detailed questions about usage, audience, and longevity. | Gives a quick quote based only on page count and quantity. |

| Proofing | Offers multiple rounds of digital and physical proofs. | Offers a single, quick digital proof, rushing approval. |

| Material Samples | Provides a curated sample kit with relevant options. | Sends random, low-quality samples or has none at all. |

| Project History | Shows a portfolio of complex, similar religious texts. | Has a portfolio of simple notebooks or commercial flyers. |

| Communication | Provides a dedicated project manager and clear timelines. | Communication is slow, unclear, or passed between people. |

Choosing a partner with these expert qualities ensures your project is in safe hands from start to finish.

How Can You Verify a Manufacturer’s Expertise with Sacred Texts?

Anyone can claim to be an expert, but with sacred texts, you need undeniable proof. The sensitivity of the content means you cannot afford to take a supplier at their word. You are entrusting them with something deeply important to your community. So how do you move past the sales pitch and truly confirm their ability to handle such a delicate and precise project?

To verify a manufacturer’s expertise, demand to see physical samples of past religious publications they have produced. Scrutinize these for typesetting accuracy, especially with special characters or non-Latin scripts. Ask for client references from other religious organizations and follow up with them. Finally, discuss their specific quality assurance protocols for ensuring textual integrity, from digital file verification to final press checks. Their response will reveal their true level of experience.

Verification is an active process. You have to dig deep and ask the tough questions. I once worked on a bilingual study guide, and the accuracy of two different scripts on the same page was critical. We sent a small, complex test file to three potential manufacturers. One returned it with alignment errors, another misunderstood the direction of the script, and only one got it perfect. That simple test told us everything we needed to know and saved us from a potential disaster.

The Power of Physical Samples

Digital proofs are useful, but they don’t tell the whole story. You need to hold the work in your hands. When a manufacturer sends you samples, check for these specific things:

- Print Clarity: Is the ink crisp and consistent, especially on very thin paper? Is there any "ghosting" or ink bleeding through the page?

- Binding Strength: Open the book and lay it flat. Does the spine feel strong? A smyth-sewn binding is usually best for durability and lay-flat use.

- Cover Finishing: Examine any foil stamping, debossing, or other decorative elements. Are the lines sharp? Is the foil applied evenly without flaking?

- Textual Alignment: For bilingual texts, are the columns perfectly aligned? For texts with footnotes or annotations, is the layout clean and easy to read?

The Importance of References

A confident manufacturer will gladly provide references. When you contact these references, don’t just ask if they were "happy." Ask specific questions to gauge the experience:

- "How did the manufacturer handle your correction and revision process?" This reveals their flexibility and attention to detail.

- "Were there any unexpected issues with quality or shipping, and how were they resolved?" This tests their problem-solving skills and transparency.

- "Did the final product match the approved sample in every way?" This confirms their consistency.

A manufacturer’s past performance is the best indicator of future success. Taking the time to verify their claims is the most important investment you can make in your project.

What Customization Options Are Critical for Religious Publications?

Religious publications are not generic products; they are tactile experiences designed for reverence and long-term use. The right customization choices elevate a simple book into a cherished object. But with so many options available, which ones truly matter for this specific market? Focusing on the wrong features can add unnecessary cost without adding real value for the end user.

The most critical customization options are those that enhance durability and usability. This includes high-quality, smyth-sewn binding that allows the book to lay flat, durable cover materials like genuine leather or premium leatherette, and thin, opaque bible paper to manage high page counts. Additional features like ribbon markers, gilded edges, and custom debossing for titles or symbols are also essential for creating a traditional, high-value feel that users expect.

Customization should always serve a purpose. For religious texts, that purpose is twofold: to honor the content and to serve the reader. I remember a project for a daily devotional. We chose a flexible, soft-touch cover instead of a rigid one because we knew users would be carrying it with them. We also added two ribbon markers—one for the daily reading and one for a favorite passage. These small, thoughtful decisions dramatically improved the user’s experience. Good customization is about understanding how the book will be used in daily life.

Functional Customization

Functionality comes first. A book that falls apart is useless, no matter how beautiful it looks.

- Binding: For any sacred text meant for study, smyth-sewn binding is the gold standard. The pages are stitched together in signatures, making the book incredibly strong and allowing it to open flat on a desk without breaking the spine. Avoid cheaper options like perfect binding (glued spines) for texts that will be used frequently.

- Paper: Bible paper (or scripture paper) is a specialty product. It’s very thin and lightweight, which is necessary for books with thousands of pages, but it must also be highly opaque to prevent text from showing through. A good manufacturer will offer different weights (grams per square meter, or gsm) and opacities.

- Cover Material: The cover protects the book and provides the first tactile impression. Options range from bonded or genuine leather for premium editions to durable, vegan-friendly leatherette and classic cloth-bound hardcovers. The choice depends on your audience, price point, and desired feel.

Aesthetic and Usability Customizations

Once function is assured, you can focus on aesthetics and user-friendly features.

- Page Edges: Gilded or colored edges add a touch of elegance and help protect the page block from moisture and dust.

- Ribbon Markers: Essential for navigation. High-quality satin ribbons are a small detail that adds significant value. You can even include multiple ribbons in different colors.

- Head & Tail Bands: These are small decorative bands of cloth at the top and bottom of the spine that add a finished look and a bit of structural reinforcement.

- Stamping and Debossing: Using foil stamping or debossing to apply titles, logos, or religious symbols to the cover creates a classic, tactile effect that printing cannot replicate.

Each of these options contributes to a final product that feels substantial, thoughtful, and worthy of its contents.

Conclusion

Finding the right manufacturer for a religious publication is a journey of careful evaluation. It requires you to look beyond price and focus on precision, quality, and a shared respect for the project’s significance. By verifying expertise, choosing meaningful customizations, and building a true partnership, you can create a publication that will serve its community for years to come.