Have you ever admired the shimmering gold edges on a premium Bible and wondered about the magic behind it? As a buyer, this lack of clarity can make it difficult to assess quality and cost. You might worry about sourcing a product that doesn’t meet your brand’s high standards, leaving you with a finish that tarnishes or peels.

The golden edge on a Bible is created through a process called edge gilding. First, the pages of the book block are trimmed perfectly smooth. Next, a special adhesive, or sizing, is applied to the edge. Then, a very thin sheet of gold leaf or imitation gold foil is carefully laid over the adhesive. Once dry, it is polished to a brilliant, smooth shine. This technique protects the pages from dust and moisture while adding a touch of luxury.

This beautiful finishing touch seems simple, but it’s a craft that blends centuries of tradition with modern manufacturing precision. Getting it right is key to producing a book that not only looks premium but also feels durable in a customer’s hands. As someone who works with factories on these details every day, I’ve learned that understanding the nuances is crucial. Let’s explore the terminology, techniques, and production considerations so you can confidently source these beautiful products.

What Are Gold Edges on Books Called?

You see a book with shiny golden edges, but what’s the right term to use with a supplier? Using incorrect terminology like "gold-painted" or "gold-dipped" can cause confusion and lead to receiving a sample that doesn’t match your vision. This communication gap can waste time and money, making it harder to get your product right.

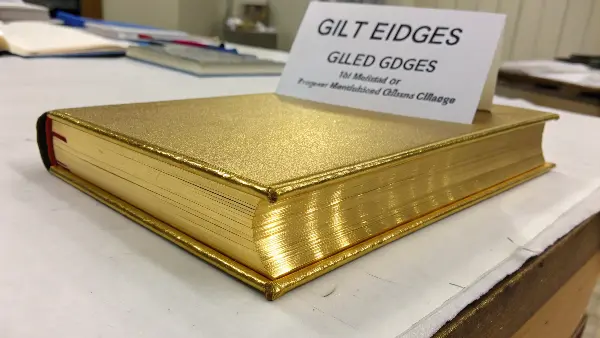

The correct term for these decorated edges is "gilt edges" or "gilded edges." The process itself is known as "edge gilding." This specific vocabulary tells a manufacturer that you expect a high-quality finish using leaf or foil, not just paint. Using precise terms like this ensures your specifications are understood and you can communicate effectively with production partners.

Getting the language right is the first step in sourcing any specialized product. In my early days, I once asked a supplier for "gold-colored edges," and the first sample I got back had been spray-painted. The paint bled into the pages, and the finish was uneven. It was a valuable lesson in precision. Let’s break down the key terms so you can communicate with total clarity.

Clarifying the Terminology

The world of bookbinding has its own specific language. When you’re developing a product, using the right words is essential for getting the result you want. "Gilding" is a broad term for applying a thin layer of gold to a surface, but in book production, it almost always refers to the edges.

Here’s a breakdown of common terms and what they mean:

| Term | Description | Common Use Case |

|---|---|---|

| Gilt Edges | The finished result. This refers to the book edges that have been covered in gold. | Describing the final feature on a product spec sheet. |

| Edge Gilding | The name of the process of applying the gold finish to the book block’s edges. | Instructing a factory on the manufacturing process required. |

| Fore-edge Painting | An entirely different technique where a scene or design is painted on the page edges. The art is often invisible when the book is closed but revealed when the pages are fanned. | High-end artisanal books, a very specialized and costly feature. |

| Edge Staining/Spraying | Applying a solid color (often with ink or paint) to the book edges. It’s a more common and less expensive alternative to gilding. | Used on many commercial journals, planners, and novels for a pop of color. |

When you specify "gilt edges" for your project, you’re signaling a desire for a classic, high-end finish. You can also have "silver gilt" or "copper gilt" edges, which follow the same process but use different metallic foils. Understanding these distinctions helps you navigate conversations with manufacturers and ensures everyone is on the same page.

What Is the Gold Leaf Technique?

You’ve decided on gilt edges, but you hear terms like "real gold leaf" and "imitation foil." What’s the difference? Choosing the wrong material could mean your product either costs too much or fails to deliver the lasting quality your customers expect. A finish that tarnishes or flakes off can quickly damage your brand’s reputation for quality.

The gold leaf technique, or gilding, is the art of applying ultra-thin sheets of gold to a surface. For book edges, this involves using either genuine gold leaf, which is real gold hammered into sheets, or imitation leaf (often brass or aluminum foil). Real gold offers unmatched brilliance and will never tarnish, while imitation leaf is a cost-effective alternative that provides a similar look but may oxidize over time without a protective sealant.

The choice between real and imitation gold leaf is one of the most important decisions you’ll make when specifying a gilt-edge product. I once worked on a premium journal line where the client insisted on the best possible finish. We opted for 22-karat gold leaf. The final product was stunning, and its perceived value was significantly higher. For a different, more trend-focused project, we used colored imitation foils to great effect.

Understanding the Material: Real vs. Imitation

The material you choose directly impacts the final product’s cost, appearance, and longevity. Both real gold leaf and imitation foil have their place, but they serve different market needs.

Real Gold Leaf

This is the traditional and most premium option. Gold is hammered into incredibly thin sheets, often just a few micrometers thick.

- Pros:

- Lustre: It has a deep, warm brilliance that is hard to replicate.

- Durability: Real gold does not tarnish or corrode, so the finish will last for generations.

- Prestige: It immediately signals a high-value, luxury product.

- Cons:

- Cost: It is significantly more expensive due to the price of gold.

- Handling: It is very delicate and requires skilled artisans to apply properly, which can add to labor costs.

Imitation Leaf (Composition Leaf or Dutch Metal)

This is the most common material used in modern mass production. It is typically made from a brass alloy (copper and zinc) or aluminum that is processed to look like gold.

- Pros:

- Cost-Effective: It allows you to achieve a gold look for a fraction of the cost.

- Versatility: It comes in a wide range of shades, including gold, silver, copper, and other metallic colors.

- Ease of Use: It is slightly thicker and more robust than real gold leaf, making it better suited for high-speed machinery.

- Cons:

- Tarnishing: Because it’s often made of brass, it can oxidize and darken over time if not protected with a clear lacquer or sealant.

- Lustre: While shiny, it often lacks the deep, warm glow of real gold.

For a product like a Bible or a special edition classic, real gold leaf reinforces its status as an heirloom. For stylish notebooks, planners, or journals, a high-quality imitation foil with a protective coating is usually the perfect balance of cost and aesthetics.

How to Make Gilded Book Edges?

You now know the terms and materials, but how does the gold leaf actually get onto the book? You might picture a slow, manual process, making you question if it’s scalable for a large order. Without understanding the production steps, it’s hard to discuss timelines and quality control points with your supplier.

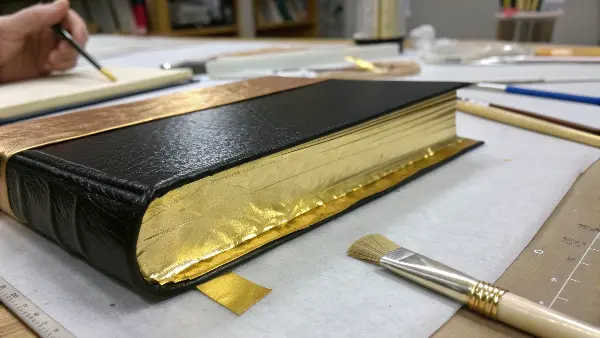

To make gilded edges, the book block is first clamped and its edges are sanded perfectly smooth. A layer of sizing (adhesive) is applied and allowed to become tacky. Then, the gold leaf or foil is carefully laid over the sized edge. For traditional gilding, the edge is then burnished with a tool to create a brilliant shine. In modern production, this process is often automated with machines that sand, apply foil with heat and pressure, and trim the excess.

Seeing the process firsthand on a factory floor was an eye-opener for me. The traditional method is a true art form, slow and deliberate. In contrast, the modern production line is a model of efficiency, capable of gilding thousands of units per day. Both methods can yield beautiful results, but they are suited for different scales and quality expectations. Understanding both helps you choose the right partner for your project.

From Traditional Craft to Modern Production

The method used for gilding will depend on the factory’s capabilities, your order volume, and your quality requirements. Here’s a look at how the two approaches differ.

Traditional Hand-Gilding

This method has been used for centuries and is reserved for high-end, small-batch, or bespoke bookbinding.

- Preparation: The book block is secured in a press. The edges are sanded with progressively finer sandpaper until they are as smooth as glass. Any imperfection will show in the final finish.

- Sizing: A base coat, often a mix of chalk and paste called "gesso," is applied and sanded again. Then, a sizing liquid (traditionally made from egg white, called "glaire") is brushed onto the edge. This acts as the adhesive.

- Laying the Leaf: The artisan waits for the sizing to reach the perfect level of tackiness. Then, using a special brush, they delicately pick up a sheet of gold leaf and lay it onto the edge.

- Burnishing: After the sizing has dried completely, the gilder polishes the gold a with a smooth, hard tool, often made of agate stone. This is what creates the mirror-like shine.

Modern Machine Gilding

This method is used for mass production and offers consistency and speed.

- Trimming & Sanding: Book blocks are fed into a machine that uses high-speed cutters and sanding belts to prepare the edges automatically.

- Foil Application: Instead of liquid sizing and delicate leaf, this process uses gilt foil on a roll. The foil has a heat-activated adhesive layer. The machine presses a heated silicone roller or die against the foil and the book edge. The heat and pressure transfer the metallic layer from the carrier film to the book edge.

- Finishing: The machine automatically advances the foil, and the finished book blocks are ejected, ready for the next stage of binding. The process is fast, clean, and highly repeatable.

While hand-gilding offers unparalleled craftsmanship, modern machine gilding makes this beautiful finish accessible for commercial products. When talking to a supplier, ask about their process—it will tell you a lot about their capabilities.

What Should Buyers Consider for Gilt-Edge Production?

You’re ready to place an order for gilt-edge notebooks. What questions should you ask your supplier? Overlooking key details like durability testing or finishing options can lead to customer complaints down the line. A beautiful sample is great, but you need to ensure the final production run maintains that quality.

As a buyer, you must clarify the material (real vs. imitation leaf), specify the finish (shiny vs. matte), and request durability tests. Ask your supplier if they apply a protective sealant over imitation foil to prevent tarnishing. Also, discuss the edge preparation, as a smoother edge results in a better finish. Finally, always get a pre-production sample to approve the color and quality before mass production begins.

I’ve built a checklist that I run through with every new gilding project. It helps prevent misunderstandings and ensures the final product is exactly what my brand envisioned. For example, I always request an "adhesion test," often done with a piece of tape, to make sure the foil won’t flake off. It’s these small quality control steps that protect your investment and your brand’s reputation.

Your Sourcing Checklist for Gilt Edges

Before signing off on a production order, having a clear and detailed specification sheet is essential. Use this checklist as a guide for your discussions with potential suppliers.

Key Specification Points

-

Material:

- Be explicit: "Imitation gold foil (brass-based)" or "22-karat genuine gold leaf."

- If using imitation foil, ask: "Do you apply a protective anti-tarnish sealant or lacquer?" This is non-negotiable for ensuring longevity.

-

Finish & Color:

- Specify the lustre: "High-gloss/burnished finish" or "Matte/satin finish."

- Request their color swatch book for foils. "Gold" can range from a yellow-gold to a rose-gold hue. A Pantone metallic color is a good reference, but always approve a physical sample.

-

Edge Preparation:

- Ask about their process: "How smooth will the edge sanding be?" A smoother edge yields a more reflective finish. For round-cornered books, confirm they can gild the curve smoothly without wrinkles.

-

Durability & Quality Control:

- Request specific tests: "Please perform a cross-hatch adhesion test on the pre-production sample." This ensures the foil is properly bonded.

- Check for consistency: "What measures do you have in place to ensure color and finish consistency across the entire production run?"

-

Sampling:

- Material Sample: First, get a swatch of the actual foil they will use.

- Pre-Production Sample (PPS): Always get a fully finished book with the gilding applied. This is your final chance to approve everything—color, smoothness, shine, and durability—before thousands are made.

By being thorough and asking these questions, you position yourself as a knowledgeable partner. It helps the factory understand your quality standards and reduces the risk of costly errors. This proactive approach is the secret to sourcing beautiful, high-quality gilt-edge products that your customers will love.

Conclusion

Understanding the art and science behind gilt edges transforms you from a simple buyer into a knowledgeable product developer. Knowing the right terms, materials, and production methods empowers you to communicate clearly with suppliers, control for quality, and create products that truly shine. This expertise is key to bringing premium, durable, and beautiful stationery to market.