Choosing the right binding for religious texts is crucial. These books are used daily, often for decades, and a weak binding will fail, leading to loose pages. This reflects poorly on the publisher and undermines the book’s purpose. Understanding the core differences between Smyth sewn and PUR binding is the key to ensuring true longevity and creating a cherished item.

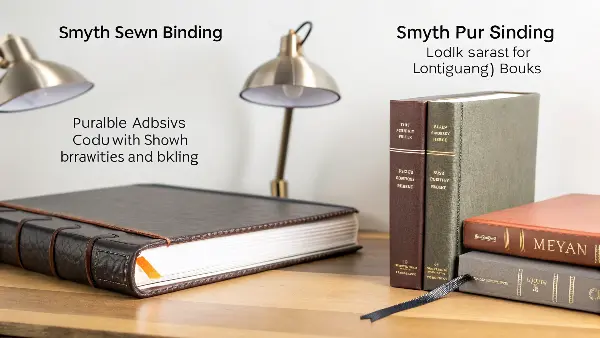

For religious books requiring ultimate durability and a lay-flat design, Smyth sewn binding is superior. The pages are physically stitched together in sections before being glued, creating an incredibly robust and flexible book block. While PUR binding is very strong and a great modern alternative, the sewn construction of Smyth binding offers unparalleled longevity for books intended for frequent, long-term use. This makes it the gold standard for heirloom-quality Bibles, prayer books, and hymnals.

Choosing a binding method isn’t just a technical decision; it’s about defining the life and feel of the book. For texts that hold deep personal or spiritual meaning, the physical quality must match the importance of the content. A Bible or a prayer book is a companion, and its construction should support a lifetime of study and reflection. As suppliers, we guide clients like you through this choice every day. Let’s break down exactly what makes these methods different so you can make the best decision for your project.

What Makes Smyth Sewn the Gold Standard for Durability?

You’ve probably heard that Smyth sewing is the "best" binding, but do you know why? Without understanding the mechanics behind it, you might be choosing it based on reputation alone, potentially overspending or using it for a project where it isn’t necessary. This uncertainty can lead to a poor investment, something we all want to avoid.

Smyth sewn’s durability comes from its unique construction. Pages are folded into groups called "signatures," and a specialized machine sews through the fold of each one, stitching them all together with thread. This creates a solid book block that is then attached to the cover. This method physically prevents individual pages from ever falling out and allows the book to lie completely flat when open, reducing stress on the spine over decades of use.

I remember a project we did for a client in Germany who was developing a premium line of academic journals. They needed the books to withstand constant use in libraries and feel substantial in the hands of researchers. He was leaning towards a high-end perfect bind, but I encouraged him to consider Smyth sewn. I showed him a sample, opening it completely flat on the table. The way the pages stayed open without any pressure on the spine convinced him immediately. It’s that physical, tangible quality that sets Smyth sewn apart.

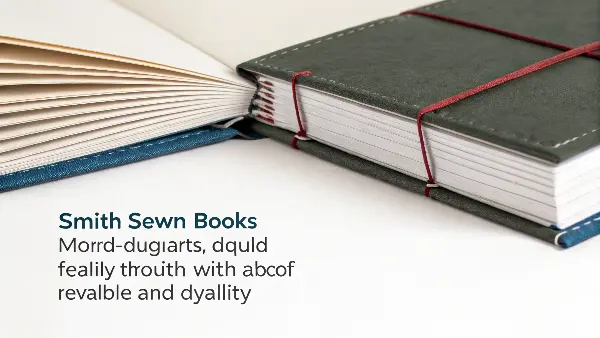

The Signature and Sewing Process

The foundation of the Smyth sewn method is the "signature." Imagine a large sheet of paper with 16 pages of the book printed on it. This sheet is folded multiple times until it becomes a small booklet of 16 pages in the correct order. This booklet is one signature. The book is built by stacking these signatures together. A special industrial sewing machine then passes a needle and thread through the center fold of each signature, linking them all together. This is fundamentally different from other methods that rely solely on glue.

The Benefit of Lay-Flat Design

Because the signatures are sewn together, the book block is incredibly flexible. The spine isn’t a rigid, glued board. Instead, it can curve and bend freely, allowing the book to open and lie perfectly flat on any page. This has two key advantages:

- Usability: For holy books, musical scores, or reference texts, the ability to stay open hands-free is a massive benefit.

- Durability: A lay-flat design removes stress from the spine. You aren’t forcing the book open against a stiff glue line, which is what causes traditional bindings to crack and fail over time.

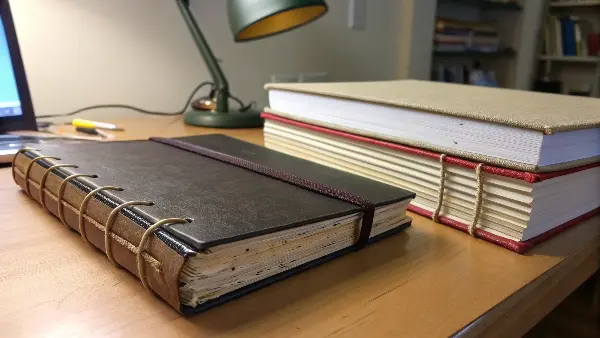

A Structure Built for Longevity

The combination of sewn signatures and a flexible spine creates a book that is built to last for generations. Let’s compare the key attributes that contribute to its longevity.

| Feature | Smyth Sewn | Impact on Durability |

|---|---|---|

| Page Security | Pages are physically stitched into signatures. | It’s virtually impossible for a single page to fall out. |

| Spine Flexibility | Excellent; allows the book to lie completely flat. | Reduces stress on the spine glue, preventing cracking. |

| Glue Reliance | Minimal glue is used to attach the block to the cover. | The core strength comes from the thread, not the adhesive. |

| Repairability | Can be repaired by a professional bookbinder. | This extends the book’s life even further for heirloom pieces. |

The sewing process creates a connected whole, a unified book block where every page supports the others. This is why it remains the undisputed champion for producing true heirloom-quality religious books meant to be passed down through families.

How Does PUR Binding Compare to Traditional Perfect Binding?

Many people hear "perfect binding" and immediately think of cheap paperbacks with cracked spines and loose pages. This common misconception can cause you to dismiss a powerful and cost-effective option for your project. The truth is, the introduction of PUR adhesive has completely changed the game, making modern perfect binding a different category altogether.

PUR (Polyurethane Reactive) binding is a huge upgrade over traditional perfect binding, which uses EVA (Ethylene Vinyl Acetate) glue. PUR adhesive is far stronger, more flexible, and resistant to extreme heat and cold. While both methods involve gluing individual pages to the spine, PUR’s chemical reaction creates a bond that is almost impossible to break, offering durability far superior to EVA perfect binding. This makes it a strong contender for many high-use books.

A few years ago, we worked with a large educational publisher on a series of textbooks. Their primary concern was durability, as the books would be handled daily by students. Their budget, however, didn’t quite stretch to Smyth sewn for the entire series. We ran a series of stress tests comparing EVA perfect binding to PUR. The EVA-bound books started shedding pages after repeated, aggressive flexing. The PUR-bound books, however, held up remarkably well. We even tried to pull pages out by hand and couldn’t. This test gave the client the confidence to choose PUR, saving them a significant amount of money without sacrificing the performance they needed.

What is Traditional EVA Perfect Binding?

The "perfect binding" that most people are familiar with uses Ethylene Vinyl Acetate (EVA), which is essentially a type of hot-melt glue. In this process, the individual pages are stacked into a block, the spine edge is roughed up to increase surface area, and the hot EVA glue is applied. The cover is then wrapped around it. The main problem is that EVA glue dries into a relatively brittle state. Over time, and especially with exposure to temperature changes, it can crack, and pages will begin to fall out.

The PUR Adhesive Revolution

PUR (Polyurethane Reactive) adhesive is a completely different kind of glue. It’s also a hot-melt adhesive, but it reacts with moisture in the air to cure and form an incredibly strong and flexible bond. This chemical reaction is what makes it so different from EVA.

Here’s a breakdown of why PUR is so much better:

| Feature | EVA (Traditional) | PUR (Modern) |

|---|---|---|

| Bond Strength | Moderate | Extremely high. 40-60% stronger than EVA. |

| Flexibility | Becomes brittle over time. | Remains highly flexible, preventing spine cracking. |

| Temperature Resistance | Can melt in high heat or crack in the cold. | Unaffected by temperatures from -20°F to 250°F. |

| Lay-Flat Ability | Poor. Resists being opened flat. | Good. Can lay flatter than EVA, but not as flat as Smyth sewn. |

| Ink/Coating Adhesion | Struggles to stick to coated or digitally printed paper. | Excellent adhesion to all paper types and finishes. |

When to Choose PUR Over Traditional Perfect Binding

You should almost always choose PUR over traditional EVA binding if durability is a factor. PUR stands up to heavy use, making it suitable for high-quality softcover books, corporate reports, manuals, and even some religious texts that have a shorter expected lifespan or tighter budget constraints. While it doesn’t offer the absolute "forever" quality of Smyth sewn, it bridges the gap beautifully, offering near-sewn strength at a more accessible price point.

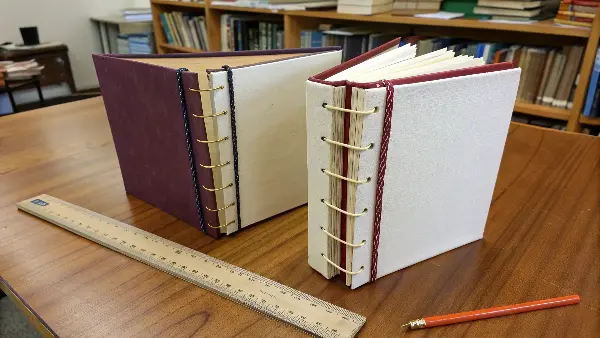

Is Thread Sewn Always Better Than PUR Perfect Binding?

It’s easy to declare a single winner, but the reality is more nuanced. As a product developer, you need the right solution for the right project, not just the most expensive one. While Smyth sewn (a type of thread sewing) is technically superior in structure, it comes at a higher cost and longer production time. This makes the choice a strategic one.

While thread sewn (Smyth sewn) binding offers the highest level of structural integrity and longevity, it isn’t always the "better" choice. PUR perfect binding provides exceptional strength and flexibility at a lower cost, making it a more practical solution for many projects. The best choice depends entirely on the book’s intended use, lifespan, and budget. For an heirloom Bible, sewn is better. For a weekly study guide, PUR is often the smarter choice.

I often consult with clients who are launching new product lines. One was developing a series of beautiful, high-design notebooks. They initially insisted on Smyth sewn for all of them. After we discussed the target customer and price point, we realized this would make the notebooks too expensive for the market. We decided to create a two-tiered system: a premium "Legacy" collection using Smyth sewn binding for journaling enthusiasts, and a vibrant, everyday collection using PUR binding for students and office workers. This allowed them to capture both ends of the market effectively.

A Head-to-Head Comparison: Use Case Matters

The decision between Smyth sewn and PUR really comes down to balancing three factors: longevity, user experience, and cost. Neither is universally "better"; they simply serve different purposes. Let’s look at a practical scenario-based comparison.

| Scenario / Factor | Best Choice: Smyth Sewn | Best Choice: PUR Binding |

|---|---|---|

| Intended Use | Anything meant to be an heirloom: Family Bibles, altar books, limited edition art books, archival records. | High-use items with a 5-15 year lifespan: Textbooks, high-quality journals, corporate annual reports, catalogs. |

| User Experience Goal | Must lay completely flat for hands-free use (e.g., hymnal, cookbook, musical score). | Needs to be durable and lay relatively flat, but can be held open (e.g., novel, manual). |

| Print Run Size & Budget | Smaller, premium runs where cost is a secondary concern. The per-unit cost is higher. | Larger runs where budget is a primary driver. Offers significant cost savings over sewn methods. |

| Production Speed | Slower process due to the mechanical sewing stage. | Faster process, as it’s a more streamlined gluing operation. |

Making the Right Call for Religious Books

When we apply this framework specifically to religious books, the picture becomes clearer.

- Main Congregation Bibles & Pulpit Bibles: These should almost always be Smyth sewn. They are handled by countless people over many years and must endure. The lay-flat nature is also essential for reading during services.

- Personal Study Bibles: This is a gray area. A premium leather-bound study Bible intended for a lifetime of notes should be Smyth sewn. An affordable paperback study Bible for a specific course could be PUR bound to keep it accessible.

- Hymnals and Prayer Books: Smyth sewn is highly recommended. These books are constantly opened wide, putting immense stress on the spine.

- Weekly Bulletins or Short-Term Study Guides: PUR binding is a perfect fit. It provides more than enough durability for the item’s intended lifespan at a fraction of the cost.

The best binding isn’t just about the physical object; it’s about aligning the construction quality with the purpose and value of the content inside.

Conclusion

In the end, for religious books demanding the ultimate durability for multi-generational use, Smyth sewn binding remains the unmatched gold standard. Its stitched construction provides a level of strength and lay-flat functionality that glue alone cannot replicate. However, PUR binding is a fantastic, modern alternative that offers incredible strength, making it a smart and cost-effective choice for many applications.