Are you captivated by the delicate, premium feel of Bible paper and wondering if you can use it for your next color printing project? The thought of vibrant images on such thin paper often leads to concerns about ink bleeding and ruining the final product. However, with the right knowledge and techniques, successfully printing color on this unique paper is achievable.

Yes, color printing on Bible paper is possible, but it comes with specific challenges. The key is to manage ink saturation to prevent bleed-through and ghosting on this lightweight material (typically 25-40 GSM). While full-color photographs are difficult, lighter color graphics, logos, and line art can be printed effectively. Success often depends on using specialized techniques like UV offset printing and working closely with a supplier who understands the paper’s limitations and can run proper tests.

So, how do we navigate these challenges to bring color to such a delicate material? It’s not just about adjusting the ink; it requires a deep understanding of the paper itself. To truly unlock its potential, we first need to explore what makes Bible paper so unique. Let’s break down the specifics of this special paper and see how its properties influence the printing process.

What Kind of Paper Is Used to Print Bibles?

When you’re sourcing materials for a large-volume book or a high-end journal, you might be looking for a lightweight yet premium paper. Using standard paper could make your product too bulky and heavy, missing the mark on elegance and portability. The paper you are likely thinking of is Bible paper, a material specifically engineered to meet these precise demands.

Bibles are printed on a special type of thin, lightweight paper called “Bible paper” or “Scritta paper.” It is an uncoated, wood-free paper made from high-quality materials like cotton or flax fibers blended with chemical pulp. This composition gives it incredible strength and opacity despite its low thickness. This unique combination allows thousands of pages to be bound into a single book without it becoming excessively large or heavy, making it perfect for reference books, dictionaries, and luxury stationery.

Deconstructing Bible Paper: More Than Just Thin

The term "thin" doesn’t do justice to the complex engineering behind Bible paper. Its creation is a careful balancing act between reducing weight and maintaining performance. The magic lies in both its composition and manufacturing process. Unlike standard paper made primarily from wood pulp, Bible paper often incorporates superior fibers like cotton and flax. These long, strong fibers are fundamental to its durability.

During manufacturing, these fibers are beaten extensively. This process increases the surface area of the fibers, allowing them to bond more tightly and create a dense, strong sheet. In addition, mineral fillers like titanium dioxide or calcium carbonate are added. These fillers are not just for bulk; they scatter light, significantly increasing the paper’s opacity. This is why you can read the text on one side of a page without being too distracted by the text on the back, a phenomenon known as "ghosting."

Here is how it compares to the paper you might use for a standard novel or report:

| Feature | Bible Paper (Scritta) | Standard Book Paper (Offset) |

|---|---|---|

| Material Base | Cotton/flax, chemical pulp | Mostly wood pulp |

| Typical Weight | 25 – 50 GSM | 80 – 120 GSM |

| Opacity Level | High for its weight | Moderate to High |

| Texture & Feel | Silky, delicate, yet strong | Smooth, thicker, more rigid |

| Primary Use Case | Bibles, dictionaries, luxury journals | Novels, textbooks, corporate reports |

Understanding these properties is the first step toward figuring out how to print on it effectively.

What GSM Is Bible Paper?

You may be trying to specify paper for a project where portability and page count are critical. Choosing a paper that is too heavy will result in a thick, unwieldy book, but choosing one that is too thin risks being fragile and transparent. Finding that perfect balance is key, but the technical specifications can be confusing, especially with specialty papers.

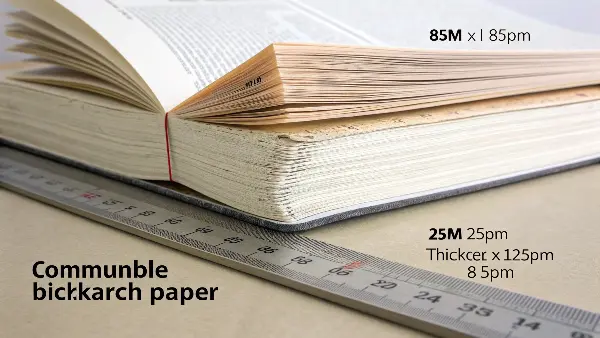

Bible paper typically ranges from 25 to 50 grams per square meter (GSM). The most common weights are between 28 GSM and 40 GSM. This extremely low basis weight is what makes it possible to print books with thousands of pages while keeping them lightweight and compact. For comparison, standard office paper is usually 80 GSM, making even the thickest Bible paper significantly lighter and thinner. The choice of GSM depends on the desired balance between opacity, durability, and a book’s final thickness.

How GSM Impacts Your Printing Project

The GSM of Bible paper is more than just a number; it directly influences almost every aspect of your final product, from its physical feel to its printing feasibility. A lower GSM means a thinner, lighter, and more translucent page. This is ideal for maximizing page count in a compact form, but it presents the greatest challenge for printing, especially with color.

For example, a 28 GSM paper is incredibly thin, providing a very elegant feel for a luxury journal. However, it will have lower opacity and be more susceptible to ink bleed-through. Printing on this weight requires minimal ink coverage. A 40 GSM paper, while still very light, offers better opacity and a sturdier feel. This makes it a safer choice for projects that include light color accents or detailed line art.

Here’s a breakdown of how different GSM ranges for Bible paper can affect your project:

| GSM Range | Key Characteristics | Best For | Printing Considerations |

|---|---|---|---|

| 25-30 GSM | Extremely thin and light, highest page count per inch, lower opacity. | Reference books with 1,500+ pages, dictionaries where compactness is the top priority. | Black text only is recommended. Color printing is extremely risky due to bleed-through. |

| 30-40 GSM | The "go-to" range. A good balance of thinness, strength, and opacity. | Premium notebooks, journals, Bibles, and legal books. | Can handle black text and simple color accents like logos or headlines. Requires careful ink management. |

| 40-50 GSM | The "heavyweight" of Bible papers. Sturdier feel, higher opacity. | Deluxe edition books, high-end journals requiring more durability or color elements. | Offers the most flexibility for color printing, but still requires testing. Reduces the benefit of extreme thinness. |

In my experience, when a client like Michael wants to add color branding to a journal, we start the conversation at 35 GSM. We then produce samples to see if the opacity and feel meet his brand’s standards before committing to a full production run.

Why Are Bibles Printed on Such Thin Paper?

Have you ever wondered why a book containing over a thousand pages, like the Bible, isn’t as thick as a brick? It seems counterintuitive to use such delicate paper for a book meant to be read and referenced for years. Many people assume it’s simply a matter of cost, but the reality is far more practical and intentional than that.

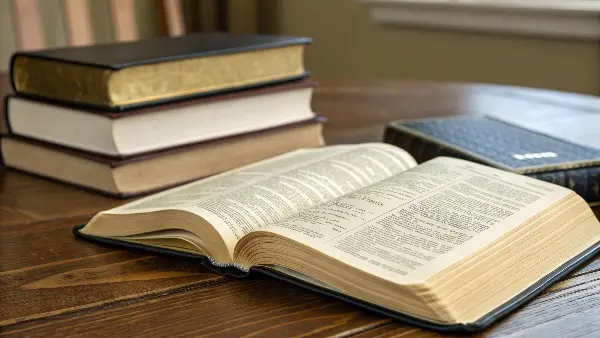

Bibles are printed on thin paper primarily to manage their physical size and weight. The Bible is a very long book, often exceeding 1,200 pages. Using standard book paper (around 80-100 GSM) would make it incredibly thick, heavy, and difficult to handle or carry. The specially engineered Bible paper (25-40 GSM) allows the entire text to be contained in a single, portable volume without sacrificing strength or readability, thanks to its high opacity and durability.

The Triad of Portability, Durability, and Readability

The choice of thin paper for Bibles is a masterful solution to a classic design problem: how to fit a massive amount of content into a user-friendly format. This decision balances three critical needs.

First and foremost is portability. Historically and today, Bibles are meant to be carried to church, used in study groups, and kept close for personal reflection. A book weighing several kilograms would fail this basic requirement. By using lightweight Bible paper, a full-text Bible becomes easy to hold, pack, and travel with. A project manager I worked with on a series of religious texts once told me, "If our customers can’t comfortably hold it to read, we’ve failed." This perfectly captures the essence of this priority.

Second is durability. It might sound contradictory, but high-quality Bible paper is surprisingly strong. As we’ve discussed, it often contains cotton or flax fibers, which are much more resilient than standard wood pulp. This ensures that the thin pages can withstand frequent turning and handling over many years without easily tearing. The paper is designed for longevity, not disposability.

Finally, there’s readability. What good is a book if the text is hard to read? Despite being thin, Bible paper has high opacity. This prevents the text from the reverse side from showing through too much, ensuring a clean reading experience.

This triad of features is what makes Bible paper the perfect material for its purpose. It’s a purposeful design choice, not a compromise.

| Feature | Design Need | How Bible Paper Solves It |

|---|---|---|

| Portability | The book must be easy to carry and hold. | Low GSM (25-40) significantly reduces overall weight and thickness. |

| Durability | The book must withstand frequent use over many years. | Strong fibers (cotton/flax) and a dense structure resist tearing. |

| Readability | Text must be clear and easy on the eyes. | High opacity from mineral fillers minimizes "ghosting" from the other side. |

Is Bible Paper Acid-Free?

When creating a premium product like a deluxe journal or a commemorative book, longevity is a primary concern. You want the paper to last for decades without yellowing or becoming brittle. This immediately brings up the question of whether the paper is archival quality, which often hinges on it being "acid-free." So, how does Bible paper stack up in this regard?

Yes, high-quality Bible paper is almost always acid-free. It is manufactured using a process that ensures a neutral or alkaline pH (7 or slightly higher). This is crucial for preventing the paper from yellowing, deteriorating, and becoming brittle over time. Acid-free paper is essential for archival purposes, making it ideal for books like Bibles, legal texts, and other important documents intended to be preserved for generations. It ensures the longevity and durability expected of such significant publications.

The Science of Longevity: pH and Paper Permanence

The term "acid-free" isn’t just marketing jargon; it’s a technical standard with a major impact on a product’s lifespan. Historically, paper was made using methods that left acidic compounds, primarily from alum-rosin sizing, within the paper. Over time, these acids break down the cellulose fibers, causing the paper to become yellow, brittle, and eventually disintegrate. You’ve surely seen this in old newspapers or paperback books from the mid-20th century.

Modern papermaking, especially for high-quality papers, has shifted to an alkaline process. Here’s what that means for Bible paper:

- Neutral pH: Acid-free paper has a pH of 7.0 (neutral) or higher (alkaline). This environment prevents the acid-hydrolysis reaction that degrades paper fibers.

- Alkaline Buffering: To further protect the paper, manufacturers often add an alkaline reserve, such as calcium carbonate. This buffer neutralizes acids that the paper might absorb from the atmosphere over time, providing long-term protection.

- Lignin-Free Pulp: High-quality Bible paper is also made from pulp that has had lignin removed. Lignin is a natural polymer in wood that also causes paper to yellow and degrade when exposed to light and air. By using "wood-free" or lignin-free pulp, its stability is further enhanced.

For a product manager like Michael in Germany, specifying acid-free paper is non-negotiable for any premium stationery line. It’s a mark of quality that assures his customers that the journal they buy today will still be a treasured keepsake in 50 years. When we supply Bible paper for such projects, providing certification of its acid-free and archival properties is a standard part of our quality assurance process. It’s a small detail that provides immense long-term value.

Conclusion

In short, printing color on Bible paper is a delicate process, but it’s far from impossible. By understanding the paper’s unique properties—its low GSM, high opacity, and acid-free nature—we can push its boundaries. With careful planning and the right technical approach, you can successfully incorporate color into your designs, creating products that are both beautiful and lightweight.