There’s nothing more frustrating than seeing a beautifully designed notebook fail because of a weak spine. The pages come loose, the cover detaches, and your quality product ends up looking cheap and unprofessional. This not only leads to wasted inventory and customer complaints but also damages the trust you’ve built in your brand.

A durable notebook spine requires choosing the right binding method for your page count and intended use. For thin notebooks, saddle-stitching is effective. For thicker ones, perfect binding or spiral/wire-o binding offer superior strength. The spine’s material, typically a heavy cardstock (250-350 gsm) or rigid greyboard, must be able to withstand repeated opening and closing without cracking or weakening.

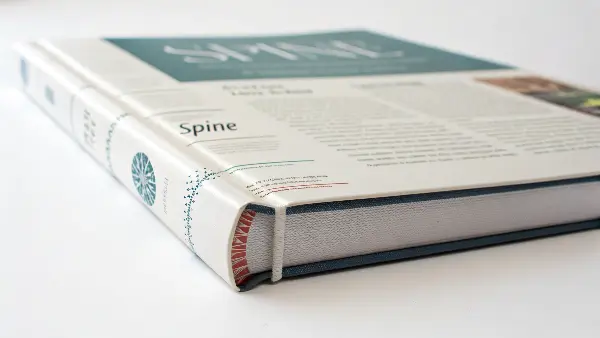

Understanding the fundamentals of spine construction is key to product longevity. But before we get into the technical details of materials and binding methods, let’s start with the basics. Why is this part of the book so critical that it shares its name with a core part of the human body? The answer reveals everything about its function.

Why Is It Even Called a Book Spine?

It might seem like a simple question, but the term "spine" isn’t just a quaint name. New product managers sometimes overlook its importance, treating it as just the edge of the book. This thinking can lead to poor design choices that compromise the entire product’s integrity. Understanding the name’s origin helps frame its structural and functional importance.

It’s called a book spine because, like the human spine, it is the central structural support that holds everything together. The spine connects the front and back covers and secures the block of paper pages, allowing the book to function as a single, cohesive unit. It provides the flexibility for the book to open and close while protecting the binding edge of the pages from damage.

Thinking of it as the book’s backbone immediately clarifies its role. It’s not just a surface for a title; it is the engineered component that ensures the notebook works. I often explain this to clients like Michael, who have a background in industrial design, because it connects the aesthetics of the cover to the mechanical function of the product.

The Structural Analogy

The human spine is a column of vertebrae that supports the entire upper body and protects the spinal cord. A book’s spine does something very similar. It bears the structural load of the covers and the weight of the paper block. It must be strong enough to keep all the pages aligned and secure, yet flexible enough to allow the covers to pivot open smoothly. If the spine fails, the entire structure falls apart, much like a serious back injury can incapacitate a person. This is why the choice of binding method—the "vertebrae" of your book—is so critical.

The Functional Purpose

Beyond just holding things together, the spine serves several functions.

- Protection: It covers and protects the glued, sewn, or stitched edge of the pages, which is the most vulnerable part of the book. Without it, pages would quickly become damaged or detached.

- Flexibility: It acts as the hinge. The creases, or "hinges," on either side of the spine of a hardcover book allow the rigid cover to open without putting stress on the spine itself. For a softcover book, the entire spine must flex.

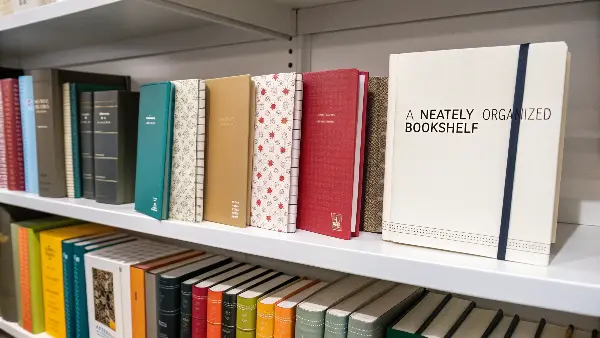

- Identification: When placed on a shelf, the spine is the only part of the book that is visible. It serves as its primary face in a retail or library environment, making the information on it—title, author, branding—absolutely essential.

Understanding this foundational concept is the first step. Next, we need to choose the right building blocks for this critical component.

What Is the Best Material for a Durable Book Spine?

You want your notebook to last, but the cover starts cracking at the spine after just a few weeks of use. This is a common quality control issue that stems directly from a mismatch between the design, the materials, and the binding method. Choosing the wrong materials can compromise even the strongest binding, leading to product failure.

The best material for a notebook spine depends on the binding style. For softcover notebooks (like perfect-bound or saddle-stitched), the spine is part of the cover, requiring a durable, coated cardstock between 250-350 gsm that can be scored and folded without cracking. For hardcover (casebound) notebooks, the spine is a rigid piece of greyboard, connected to the front and back covers with a flexible, durable covering material like cloth, leatherette, or laminated paper.

In my experience as a supplier, material selection is where theory meets reality. A product manager needs to know how these materials behave during production and in the hands of the end-user. Let’s break down the common options and how they relate to the most popular binding methods we use at Panoffices.

Materials for Softcover Bindings

Softcover bindings are common for everyday notebooks, journals, and planners. The cover is a single piece of paper that wraps around the text block.

- Saddle-Stitch: Used for thin notebooks (typically under 64 pages). The spine is simply the fold of the cover sheet, held together by staples. The material must be flexible enough to fold cleanly but sturdy enough not to tear at the staples. A 250 gsm coated stock is usually a good choice.

- Perfect Binding: This is the most common method for thicker softcover notebooks. The pages are stacked, and the edge is glued together with a strong, flexible adhesive before the cover is wrapped around it. The cover stock here is critical. It needs to be heavy enough (300-350 gsm) to provide support, and it must be properly scored. Scoring creates a crease in the paper, allowing it to fold without cracking the paper fibers or the lamination. We always recommend lamination (matte or gloss) for added durability and to prevent ink from cracking on the fold.

Materials for Hardcover (Casebound) Bindings

Hardcover notebooks signal premium quality and durability. The construction is more complex.

- The Case: The hard cover, or "case," is made from three pieces of rigid greyboard (one for the front, one for the back, and a smaller piece for the spine).

- The Covering: This greyboard structure is then covered by a single sheet of a durable and decorative material. This can be printed paper with lamination, book cloth, or a synthetic material like leatherette. The choice of covering impacts both the look and the durability. Book cloth is exceptionally strong in the hinge area.

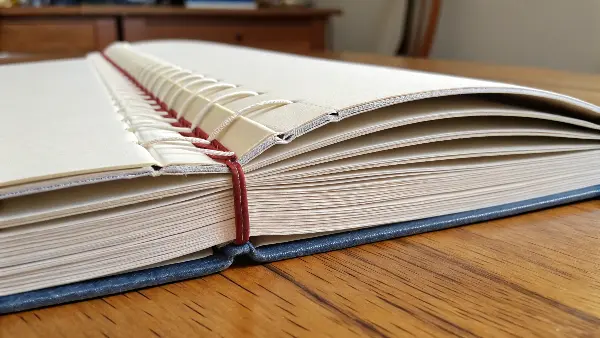

- Reinforcement: Inside, the spine is often reinforced with mull (also called crash), a starched, open-weave fabric glued to the text block spine before it’s attached to the case. This adds tremendous strength and flexibility.

| Binding Type | Spine Construction | Recommended Material | Best For |

|---|---|---|---|

| Saddle-Stitch | Folded Cardstock | 250 gsm Coated Paper | Thin booklets, promotional items |

| Perfect Bound | Glued Spine w/ Wrap-around Cover | 300-350 gsm Coated Cardstock (Laminated) | Thicker notebooks, journals, manuals |

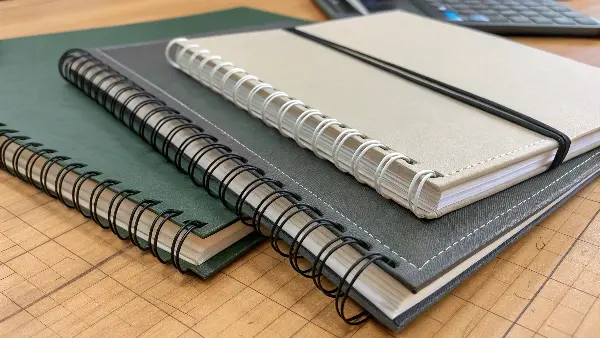

| Spiral / Wire-O | Metal or Plastic Coil | Curls through punched holes in cover/pages | Lay-flat notebooks, planners, presentations |

| Casebound (Hardcover) | Rigid Greyboard w/ Covering | Greyboard + Book Cloth or Laminated Paper | Premium journals, diaries, long-lasting notebooks |

What Makes a Good Notebook Spine?

A notebook can have the best paper and a beautiful cover, but if the spine is poorly designed, the product feels clumsy and looks unprofessional on the shelf. A good spine is more than just strong; it’s a seamless integration of function and form. Getting this balance wrong means you’ve created a product that is either frustrating to use or easy to overlook.

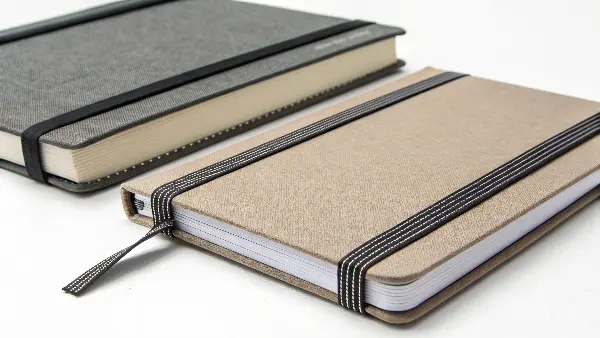

A good book spine excels in two areas: functionality and aesthetics. Functionally, it must be durable, flexible, and appropriate for the book’s page count and purpose (e.g., allowing a planner to lay flat). Aesthetically, the spine’s design must be readable, consistent with your branding, and visually appealing when stacked on a retail shelf. It should serve as a mini-advertisement for the product.

When I review a project with a client, we focus on both these aspects. A spine that cracks fails on function. A spine with unreadable text fails on aesthetics. A truly successful product gets both right. Here’s a deeper look into a checklist for a great spine.

Functional Excellence

The spine’s primary job is to work. This comes down to a few key performance indicators:

- Durability: This is non-negotiable. As discussed, it comes from matching the right materials and binding method. It should withstand thousands of open-and-close cycles without the cover detaching or the pages coming loose.

- Flexibility & Lay-Flat Ability: How the notebook behaves when open is crucial. For a journal, a perfect-bound spine that can be "broken in" is fine. But for a planner or a workbook, the ability to lay flat is essential. This is where binding methods like Wire-O or spiral binding shine. A casebound book with a sewn binding can also be designed to lay flat, offering a premium experience.

- Correct Sizing: The width of the spine must be calculated perfectly. A spine that is too narrow will cause the cover to bow outwards, looking strained. A spine that is too wide will feel loose and floppy, weakening the structure. Your manufacturer should provide a precise spine width calculation based on your paper stock and page count.

Aesthetic and Commercial Appeal

Once functionality is assured, you need to make the spine work for your brand.

- Readability: The text on the spine must be clear and easy to read from a distance. This means choosing a simple, bold font and ensuring sufficient color contrast between the text and the background. I once saw a beautiful notebook with a silver foil title on a light grey spine—it was completely illegible in the store.

- Branding: The spine is a key piece of brand real estate. Your logo or a consistent design element should be present. When a customer sees multiple products from your line on a shelf, the spines should create a cohesive, recognizable block.

- Hierarchy of Information: Decide what’s most important. Usually, this is the product title or type (e.g., "DAILY PLANNER") followed by the brand name. Keep it simple. Cluttering the spine with too much information makes it ineffective.

A great spine is the result of conscious engineering and thoughtful design, not an accident.

How Does the Spine Affect Overall Cover Design?

Designers often create stunning front covers in isolation, only to realize later that their ideas don’t work with the manufacturing process. The spine is frequently an afterthought, leading to major problems like misaligned graphics, awkward text placement, and last-minute redesigns that cause production delays. This lack of integration can ruin an otherwise perfect project.

The spine is not a separate element; it is an integral part of the wrap-around cover layout. The choice of binding method and the calculated spine width must be determined before the cover design begins. The artwork must be created as a single flat canvas—incorporating the back cover, spine, and front cover—with careful attention paid to how graphics and text flow (or don’t flow) across the scored hinge areas.

This is one of the most common technical hurdles I help my clients overcome. A successful cover design process anticipates the physical reality of the product from the very first step. Here’s how to ensure the spine is properly integrated into your cover design workflow.

Design on a Single, Flat Template

Your manufacturer should provide you with a precise template. This template will show the full, flat dimensions of the cover, including the front, back, and the exact calculated spine width. It will also include markings for bleed, trim, and the crucial score lines that separate the spine from the covers. Designing on this template is the only way to ensure proper alignment. Graphics that need to wrap around from the front cover to the spine must be positioned perfectly across these score lines. I remember a project where a client’s beautiful geometric pattern was misaligned by just two millimeters on the spine, and the entire batch had to be re-evaluated.

Respect the "No-Go" Hinge Areas

On perfect-bound and casebound books, the areas where the cover folds at the hinge are high-stress points. It’s generally a bad idea to place small, detailed text or critical parts of a logo directly on these score lines. The creasing process can slightly distort the image, and repeated flexing can cause the ink to wear away faster in this area. It’s much safer to keep important elements firmly on the flat planes of the front cover or the spine, away from the fold.

Spine Width Calculation is Everything

You cannot finalize a cover design until you know the exact spine width. This dimension depends on two factors: the number of pages and the thickness (caliper) of the paper stock you’ve chosen. A 120-page notebook using 80 gsm paper will have a much thinner spine than a 120-page notebook using 120 gsm paper. I always insist that we confirm the exact paper stock and page count with the client before their designer starts working on the cover art. Requesting a final spine width calculation from your supplier is non-negotiable.

Conclusion

A notebook’s spine is far more than just its edge. It is the structural core that determines its durability, usability, and shelf appeal. By selecting the right materials, choosing a suitable binding method, and integrating the spine’s design into the cover from the start, you can create a product that is built to last and proudly represents your brand.