Are you tired of sending RFQs to stationery suppliers, only to get back vague quotes or proposals for the wrong products? This guesswork wastes precious time, creates endless email chains, and puts your entire product launch at risk. A well-crafted RFQ template is your key to getting clear, comparable bids and the exact products you envision.

To master wholesale stationery sourcing, create a detailed Request for Quotation (RFQ) that leaves no room for error. Your RFQ should include precise product specifications, material requirements, packaging details, desired quantities, and compliance standards. Using a structured template ensures potential suppliers, like us at Panoffices, understand your exact needs. This leads to accurate pricing, faster turnaround times, and a smoother partnership from the very beginning, preventing costly mistakes and production delays.

It sounds simple, but the devil is truly in the details. A single missing piece of information can derail the entire process. I’ve seen it happen countless times in my years in this industry. A vague request leads to a vague outcome. So, let’s break down exactly what you need to include to build a bulletproof RFQ. This is the foundation for a successful and profitable sourcing relationship.

What Key Information Must Your RFQ Include for Accurate Quotes?

You send out a request for a new line of notebooks, but the quotes you get back are all over the place. One is suspiciously cheap, another is wildly expensive, and none seem to be quoting the same thing. It’s impossible to compare them, leaving you to guess which supplier truly understands your project and offers fair value.

For accurate quotes, your RFQ must include your company details, project timeline, shipping destination (Incoterms), and payment terms. Also, specify the required response deadline for the quotation. This foundational information allows suppliers to calculate accurate shipping costs, assess production capacity, and provide a comprehensive proposal that you can easily compare with others. Without these details, you’re only getting a partial picture and an unreliable price.

Before a supplier can even look at your product specs, they need to understand the business context of your request. These details frame the entire project and have a major impact on the final quote. I once worked with a new buyer who forgot to specify their needed Incoterms. They chose a quote that seemed low, only to be hit with a massive, unexpected freight bill because the price was Ex-Works (EXW), meaning they were responsible for all shipping from the factory floor. A simple detail created a huge budget problem.

To avoid this, make sure your RFQ’s introductory section is crystal clear. Think of it as the project’s business card. It tells us who you are, where you’re going, and how you work.

Essential Business & Logistical Information

| RFQ Component | Why It’s Critical | Example Detail |

|---|---|---|

| Company Information | Establishes credibility and provides contact details. | Your Company Name, Address, Contact Person, Email, Phone Number |

| Project Name/Code | Helps both you and the supplier track the specific project. | "Autumn Collection 2025 – Notebooks" |

| Response Deadline | Sets clear expectations for when you need the quotation. | "Please submit all quotes by November 15, 2024" |

| Required Quantities | This is a primary driver of cost. Provide price tiers. | "Please quote for 5,000 / 10,000 / 20,000 units" |

| Project Timeline | Allows the supplier to check production schedules. | "Sample needed by Jan 10. Mass production to complete by March 30." |

| Shipping & Incoterms | Determines who pays for and manages shipping. Crucial for cost. | "FOB Shanghai" or "DDP Hamburg, Germany" |

| Payment Terms | Clarifies the payment schedule for the order. | "30% deposit, 70% balance against Bill of Lading copy" |

Providing this information upfront shows suppliers that you are a professional and serious partner. It eliminates unnecessary back-and-forth and empowers them to give you a complete and accurate quote right away.

How Do You Clearly Specify Product Details to Avoid Misunderstandings?

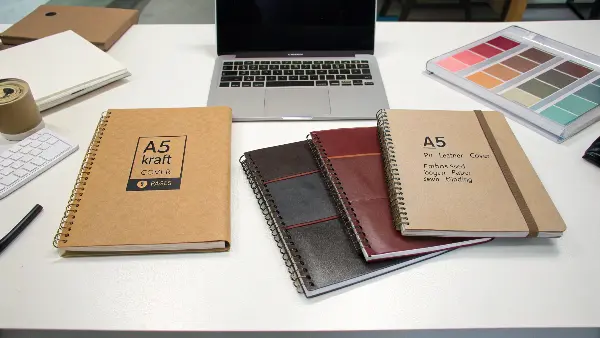

You thought you described the perfect notebook in your email—"A5, kraft cover, 80 pages." But the sample that arrives is a huge disappointment. The paper is flimsy, the cover is the wrong shade of brown, and the binding isn’t what you pictured at all. Now you’re back to square one, having wasted weeks of valuable time.

Clearly specify every product detail by breaking it down into its core components. For a notebook, this means defining the size (A5, B5), cover material (PU leather, Kraft paper), cover finish (embossing, foil stamp), inner page count, paper weight (80gsm, 100gsm), and binding type (spiral, sewn). Always provide Pantone color codes for branding and attach design files or mock-ups. The more specific you are, the less room there is for error.

This is where many buyers, even experienced ones, can stumble. General descriptions are not enough. Words like "high quality" or "thick paper" are subjective. What I consider thick paper might not be what you consider thick. You must use objective, measurable specifications to translate your vision into a concrete manufacturing blueprint. The goal is to create a spec sheet so detailed that any factory manager can read it and know exactly what to make.

As a multi-product stationery brand, your RFQs will need to cover different items. Here’s a breakdown of the critical specs for common product categories.

For Notebooks and Planners

- Dimensions: Exact height, width, and thickness (e.g., 148 x 210 mm for A5).

- Cover:

- Material: PU Leather, Hardcover (Greyboard GSM?), Kraft Paper, PP.

- Printing/Finishing: CMYK/PMS printing, Debossing/Embossing, Foil Stamping, Spot UV.

- Inner Pages:

- Sheet Count: e.g., 96 sheets (192 pages).

- Paper Weight: 80gsm, 100gsm, 120gsm (very important for ink bleed-through).

- Paper Type & Color: Wood-free paper, ivory or bright white.

- Printing: Lined, dot grid, blank, or custom planner layout (1-color or 4-color printing).

- Binding: Sewn, perfect bound, spiral (wire-o), saddle-stitched.

- Extras: Elastic band, ribbon marker, back pocket. Specify color and size.

For Pens and Writing Instruments

- Type: Ballpoint pen, gel pen, fountain pen, highlighter.

- Material: ABS plastic, metal (aluminum, brass), recycled paper barrel.

- Mechanism: Click-action, twist-action, capped.

- Refill: Ink color (black, blue), tip size (0.5mm, 0.7mm, 1.0mm), ink type (oil-based, gel).

- Branding: Barrel printing (pad print, screen print), clip engraving. Provide Pantone codes for all colors.

A spec sheet like this is your language of manufacturing. The more fluent you are, the better the final product will be.

Why Are Packaging and Labeling Specifications So Critical in Your RFQ?

Your beautifully designed stationery arrives at your warehouse. The products are perfect. But they are packaged in cheap, flimsy boxes that were crushed during shipping. Now your products look unprofessional on retail shelves, and your brand image suffers before a single sale is even made. The unboxing experience is ruined.

Packaging and labeling are critical because they protect the product, communicate your brand identity, and ensure regulatory compliance. Your RFQ must detail the primary product packaging (e.g., OPP bag, gift box), inner carton quantities, and master carton specifications (e.g., 5-ply, drop-test requirements). Include specifications for barcodes, warning labels, and country-of-origin markings to prevent damage, ensure retail readiness, and avoid customs delays.

I often tell my clients: your packaging is the first physical interaction a customer has with your brand. It must be treated with the same importance as the product itself. Neglecting it in your RFQ is a costly mistake. It not only risks product damage but also misses a key marketing opportunity and can lead to serious logistical problems. Just last year, a client’s shipment was held in customs for two weeks because the carton markings were incorrect. That delay caused them to miss a key retail deadline.

To avoid these issues, your RFQ must detail every layer of packaging and labeling.

A Three-Tiered Approach to Packaging Specs

| Packaging Tier | Purpose | Details to Specify in RFQ |

|---|---|---|

| Primary Packaging | The packaging that directly holds the product. The customer’s first impression. | Type (Printed gift box, clear PVC box, OPP bag, paper belly band), Material (e.g., 350gsm art paper), Printing (CMYK), Finishing (Matte lamination), Barcode sticker (EAN/UPC). |

| Inner Carton | Bundles a set number of products for easy handling and stock management. | Material (e.g., 3-ply corrugated cardboard), Dimensions, Quantity of units inside (e.g., 12 pcs per inner carton), Labeling (Item number, quantity). |

| Master Carton | The outer box used for shipping. Its main job is protection. | Material (e.g., 5-ply corrugated cardboard, K=K), Max Weight, Dimensions, Drop-test requirements, Shipping Marks (Company name, PO#, Carton #, Made in…). |

By clearly defining each of these elements, you’re doing three things: protecting your financial investment from shipping damage, creating a professional retail-ready product, and ensuring a smooth journey through the global supply chain. Don’t let packaging be an afterthought.

What Role Do Compliance and Quality Standards Play in Your Sourcing Request?

You’ve found a supplier offering an amazing price on a set of children’s coloring pencils. You place the order, excited about the profit margins. But then you discover the pencils contain materials that don’t meet your market’s safety regulations, like CE in Europe. Suddenly, your entire shipment is worthless and unsellable.

Compliance and quality standards are non-negotiable for market access and brand reputation. In your RFQ, clearly state all required certifications, such as FSC for paper, REACH or Prop 65 for materials, and CE for relevant items. Also, define your quality assurance (QA) expectations, like acceptable quality limits (AQL) for inspections. This ensures the supplier manufactures a product that is legal, safe, and meets your brand’s quality promise.

For buyers like Michael in Germany, this is not a "nice to have," it’s a fundamental requirement of doing business. Sourcing from Asia to sell in Europe or North America means you are the importer of record, and you are legally responsible for ensuring the products are safe and compliant. Stating these needs at the RFQ stage is the most efficient way to filter out suppliers who can’t meet your standards. Don’t wait until the samples are made to ask about FSC certification. Ask from day one.

This part of your RFQ demonstrates your professionalism and protects your business from massive risk. Here’s how to structure it.

Defining Your Standards Upfront

First, list the required certifications. Be specific.

- FSC (Forest Stewardship Council): Essential if you’re marketing your paper products as sustainable. Ask for the supplier’s FSC certificate number.

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals): A European Union regulation. It’s crucial for any product with plastics, metals, or chemicals, like pens, binders, or synthetic leather covers.

- CE Marking: Required for certain products sold in the EEA, like toys or some electronic accessories. For stationery, this could apply to things like children’s scissors or craft kits.

- BSCI or Sedex: These aren’t product certifications but social audit reports for the factory. They show the supplier adheres to ethical labor practices, which is increasingly important to consumers and large retailers.

Second, define your quality expectations. The industry standard for this is the Acceptable Quality Limit (AQL). In your RFQ, you can state something like: "Final inspection will be performed based on AQL 2.5/4.0 standards." This tells the factory exactly what level of minor and major defects you are willing to accept, setting a clear, objective benchmark for quality control.

How Can You Structure Your RFQ to Evaluate Supplier Capabilities Beyond Just Price?

The cheapest quote is rarely the best deal. We’ve all been tempted. But partnering with a low-cost supplier often leads to headaches: poor communication, missed deadlines, quality fade over time, and a total lack of collaboration on product improvements. The small amount you saved on the unit price is quickly eaten up by management time and problems.

To evaluate suppliers beyond price, include questions in your RFQ about their company. Ask for their main export markets, key customers, factory audit reports (like BSCI or Sedex), and OEM/ODM case studies. Inquire about their standard lead times for samples and mass production, and their communication process. A great partner will readily provide this information, showcasing their experience, transparency, and suitability for a long-term relationship.

Your RFQ is more than a price request; it’s the beginning of a potential partnership. A few extra questions can help you vet the company behind the quote. This is how you find a supplier who will grow with you, suggest better materials, and help you innovate. At Panoffices, we welcome these questions because they show the buyer is serious about quality and a long-term vision, just like we are.

Use your RFQ to conduct a mini-interview. Add a section called "Supplier Information" with questions designed to reveal their capabilities.

Assessing Experience and Reliability

Ask questions that prove they have a track record of success, especially in markets like yours.

- "What are your main export markets? (e.g., EU, North America, Australia)"

- "Can you provide a copy of your most recent factory social audit (BSCI or Sedex)?"

- "Can you share 1-2 case studies of similar OEM/ODM projects you’ve completed?"

Understanding Production Capacity

These questions help you gauge if they can handle your volume and timelines.

- "What is your standard lead time for pre-production samples?"

- "What is your standard lead time for mass production after a sample is approved?"

- "What is your monthly production capacity for this type of product?"

Gauging Collaboration Potential

A true partner is proactive and communicative.

- "Who will be my primary point of contact, and what are their working hours?"

- "Do you have an in-house design or product development team?"

- "How do you handle quality control during and after production?"

Including these questions transforms your RFQ from a simple shopping list into a powerful vetting tool. The answers will give you a much richer picture of the supplier, helping you choose a partner who offers true value, not just a low price.

Conclusion

Crafting a detailed RFQ is the single most important step in successful stationery sourcing. It turns ambiguity into clarity, prevents costly errors, and builds the foundation for a strong, reliable partnership. Use these guidelines to create your own comprehensive template, and you’ll be in a much better position to find the perfect supplier to bring your vision to life.