Are you trying to get a clear quote for your new stationery line, but the price variations are confusing? You see a cheaper option but worry about hidden costs or quality cuts. Making a smart sourcing decision feels impossible without the full picture. Understanding the key cost drivers helps you evaluate quotes accurately and find a partner who delivers true value.

The main costs in stationery manufacturing come from four key areas: raw materials like paper quality and type of plastic; the intensity of manufacturing processes and labor; the complexity of customization and design (OEM/ODM); and finally, packaging, logistics, and compliance testing. Each choice in these areas directly impacts the final unit price, so understanding them is crucial for effective sourcing and budgeting for your brand.

It’s a lot to juggle, I know. I’ve worked with hundreds of buyers, just like you, who need to balance budget with brand vision. The final price tag isn’t just one number; it’s a story of materials, craftsmanship, and partnership. So, let’s pull back the curtain and look at each piece of the puzzle. This breakdown will help you make better decisions for your next product launch.

How Do Raw Material Choices Impact Your Final Stationery Costs?

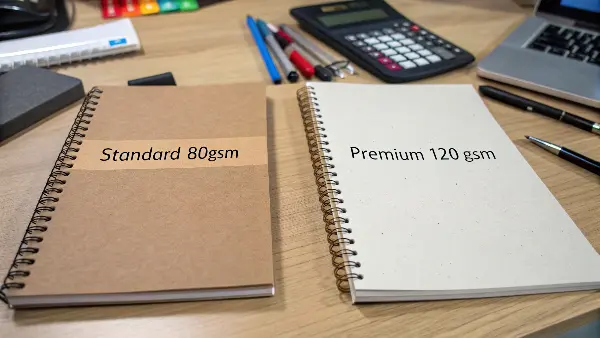

You’re choosing between a standard 80gsm paper and a premium, recycled 120gsm stock for your new notebook. The price difference is significant, and you’re not sure if your customers will notice or appreciate the upgrade. Knowing how materials affect price, quality, and brand perception allows you to make a strategic choice aligned with your goals.

Raw material choices are the foundation of your product’s cost and quality. Premium materials like thick, FSC-certified paper, high-grade ABS plastic, or German-made ink will cost more than standard options. The material’s origin, processing, and certifications all add to the price. Cheaper materials might lower the unit cost, but they can compromise the user experience, durability, and your brand’s commitment to quality or sustainability.

Dive Deeper: From Paper Pulp to Pen Plastic

Raw materials are typically the largest single component of a product’s cost. The selection here defines the look, feel, and performance of the final item. It’s the first and most important decision in the product development journey. What feels like a small choice between two types of plastic for a pen barrel can have major implications for both the cost and the customer’s perception of your brand.

The Core of the Product: Paper & Board

For any paper product, the specifications of the paper itself are paramount. It’s not just about recycled versus new. Key factors include weight (measured in grams per square meter, or gsm), finish (coated, uncoated, textured), and source certifications like FSC (Forest Stewardship Council). An 80gsm paper is standard for notebooks, but a 120gsm paper feels much more luxurious and prevents ink from bleeding through, justifying a higher retail price.

I remember a client who was developing a premium planner. We switched from a standard plastic cover to a PU leather-wrapped thick greyboard. The cost per unit increased by about 15%, but the perceived value shot up. That planner became their annual bestseller because the high-quality feel of the materials resonated with their target audience.

| Feature | Standard Option | Premium Option | Cost Impact |

|---|---|---|---|

| Paper Weight | 70-80 gsm | 100-120 gsm | Moderate Increase |

| Paper Source | Standard Pulp | FSC-Certified or Recycled | Minor Increase |

| Cover Material | Laminated Art Paper | PU Leather or Fabric | Significant Increase |

Beyond Paper: Plastics, Metals, and Inks

For items like pens and organizers, the choices are just as critical. A pen made from standard GPPS plastic is cheap, but it can feel brittle. Moving to a more durable ABS plastic adds to the cost but improves longevity. Using recycled plastics can also add cost due to processing but offers a powerful sustainability story. Even the ink is a variable. Standard ink is economical, but archival-quality or specialty gel inks from recognized sources like Germany or Japan come at a premium. These are the small details that differentiate a disposable pen from a favorite writing tool.

Do More Complex Manufacturing Processes Always Mean Higher Prices?

You’ve got a great design for a notebook with lay-flat binding and a debossed cover. Your supplier says these features will drive up the cost significantly, forcing you to choose between your design vision and your budget. Understanding which processes add the most cost helps you prioritize features and find clever solutions that achieve a premium feel.

Yes, manufacturing complexity is a major cost driver. Simple processes like standard glue binding are much cheaper than labor-intensive methods like lay-flat Smyth-sewn binding. Every extra step—like foil stamping, debossing, or die-cutting—adds machine setup time, specialized labor, and potential for waste, all of which are factored into the final price. The more unique and complex your design, the higher the manufacturing cost will be.

Dive Deeper: The Price of Craftsmanship and Assembly

After choosing your materials, the next major cost factor is how you put them together. The journey from raw materials to a finished product involves many steps, and each one has a cost associated with labor, machinery, and time. A simple design can be highly automated and produced quickly, while a complex one requires more manual intervention and specialized equipment.

Printing and Finishing Touches

A simple one-color logo print is very different from a full-color photorealistic cover. But the real cost comes from finishing techniques that give a product its tactile, premium feel. Processes like foil stamping (adding a metallic finish), debossing (pressing a design into the cover), or spot UV (a glossy coating on a specific area) each require a custom die or screen and a separate pass through a machine. This setup has a fixed cost, which is why these features have a bigger price impact on smaller order quantities.

Binding and Assembly Methods

How a notebook is held together dramatically affects its functionality and cost. We work with clients to select the right method for their budget and product goals. For example, a client wanted a lay-flat notebook for artists but was concerned about the high cost of Smyth-sewn binding. We suggested a high-quality Wire-O binding with a wrap-around hardcover, which provided the lay-flat function at a more accessible price point.

| Binding Type | Functionality | Relative Cost | Best For |

|---|---|---|---|

| Saddle Stitch | Opens flat, but not durable | Low | Thin booklets, inserts |

| Perfect Bind | Professional look, like a book | Medium | Journals, planners |

| Wire-O / Spiral | Lays completely flat, 360° fold | Medium-High | Notebooks, workbooks |

| Smyth Sewn | Lays completely flat, durable | High | Premium, archival journals |

The Role of Labor and Automation

We balance automation and skilled labor to achieve the best result. Automated lines for standard pens are incredibly efficient and keep costs down. However, assembling a custom gift set with multiple items, a ribbon, and a sticker requires careful handwork. That manual labor is more costly, but it’s essential for creating a curated product experience. It’s this combination of machine efficiency and human touch that allows for a wide range of products.

How Does Customization Affect the Price of My Stationery Order?

You want to create a truly unique stationery line, not just a generic product with your logo on it. But then you hear terms like "mold fees" and "high MOQs," and worry that real customization is out of reach for your budget. Knowing the difference between simple OEM and deep ODM helps you understand the costs so you can create a unique product affordably.

Customization costs depend on the level of change. Simple OEM (Original Equipment Manufacturer), like adding your logo and custom art to an existing product, is relatively cheap. However, deep ODM (Original Design Manufacturer), which involves creating a new product shape or mechanism, is much more expensive. This requires new molds, engineering, and prototyping, with significant upfront costs that require a higher Minimum Order Quantity (MOQ).

Dive Deeper: Bringing Your Unique Brand Vision to Life

This is where a B2B partner like us really shines. Customization is how you move from selling a commodity to creating a brand. It can be as simple as a specific color choice or as complex as inventing a whole new product. The key is to understand the cost implications of each path.

Understanding OEM vs. ODM

These two acronyms are central to custom manufacturing.

-

OEM (Original Equipment Manufacturer): This is the most common and cost-effective form of customization. You select a product from our existing catalog—say, a pen or a notebook—and we modify it with your brand’s unique printing, colors, and packaging. The underlying product structure and tooling already exist, so there are no large upfront investment costs. This is perfect for launching new lines quickly and testing market response.

-

ODM (Original Design Manufacturer): This is a deeper partnership where we help you design and engineer a product from the ground up. If you want a pen with a completely new clip design or a planner with a unique page layout and integrated pocket system, that’s ODM. It involves research, development, 3D modeling, prototyping, and creating new production tools. This is more expensive and takes longer, but the result is a proprietary product that nobody else has.

The Truth About Mold & Tooling Fees

When a client asks for a pen with a unique barrel shape, we have to create a new injection mold. This is a highly precise and durable piece of steel tooling that can cost anywhere from a few thousand to tens of thousands of dollars, depending on its complexity. This is a one-time investment. Once the mold is paid for, it can produce hundreds of thousands of units at a low per-piece cost. I always work closely with clients to ensure a design is 100% finalized before committing to this expense. We treat it as a shared investment in a long-term, successful product.

The Power of Minimum Order Quantity (MOQ)

The MOQ is the smallest number of units we can produce in a single run. It exists because every production run has fixed setup costs (cleaning machines, loading materials, calibrating printers). Spreading these fixed costs over a larger number of units lowers the price per piece. A highly custom ODM product will naturally have a higher MOQ to help absorb the significant R&D and tooling costs. I often advise clients to start with an OEM product to build volume and prove a concept. Once it’s a success, we can reinvest the profits into a next-generation ODM version.

Are Packaging and Shipping Really a Major Part of Stationery Costs?

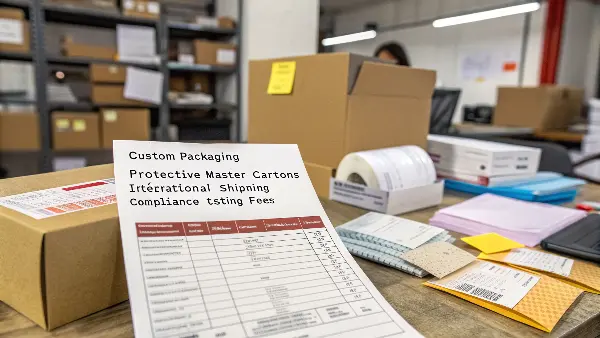

You’ve finalized your product cost and feel good about the pricepoint. Then you get the full quote including custom packaging, shipping, and duties. Suddenly, the final landed cost is much higher than you expected. Understanding these "final mile" costs upfront allows you to budget correctly and protect both your product and your profit margin.

Absolutely. Packaging and logistics are significant and often underestimated costs. Custom-printed retail packaging, protective master cartons, and international shipping from the factory to your warehouse all add up. The cost is influenced by package materials, final product size and weight, shipping method (sea vs. air), and your final destination country. Furthermore, fees for mandatory compliance testing to meet European or American standards must be factored in.

Dive Deeper: Getting Your Product Safely from Our Factory to Your Warehouse

Creating a great product is only half the battle. Getting it into your customers’ hands safely and legally is the other half. These post-production costs are not "extras"; they are an essential part of the total product cost and should be planned for from the very beginning.

More Than Just a Box: The Cost of Packaging

Product packaging serves three roles: protection, presentation, and information. A simple polybag is cheap but offers little protection and no branding. A printed belly band over a notebook is a cost-effective branding tool. A full, custom-printed retail box with a window looks fantastic on a shelf but adds significant material and labor costs. Beyond the retail box, we have to think about master cartons. We calculate the right thickness and size to ensure your products arrive pristine, not crushed. A damaged product is a 100% loss, so investing in good protective packaging is a form of insurance.

Navigating Global Logistics and Landed Cost

Shipping costs can be complex. The price to get your goods from our factory in Asia to your warehouse in Germany or the United States depends on volume, weight, and speed. Sea freight is far cheaper but takes weeks. Air freight is fast but can be 5-10 times more expensive. It’s crucial to understand basic shipping terms.

| Incoterm | What It Means | Your Responsibility |

|---|---|---|

| EXW (Ex Works) | The price at our factory door. | You handle all shipping, export, and import. |

| FOB (Free On Board) | The price includes getting it to the port and onto the ship. | You handle ocean freight, customs, and inland delivery. |

| DDP (Delivered Duty Paid) | The price for goods delivered to your warehouse door. | We handle everything. Easiest, but least transparent. |

Most of our clients, like Michael in Germany, prefer FOB because it gives them control over their shipping partners. We always provide a clear estimate of carton size and weight so their freight forwarder can give an accurate quote.

The Price of Peace of Mind: Compliance & QC

To sell a pen in Europe, it must comply with REACH regulations. To sell a children’s stationery set in the US, it needs to pass CPSIA testing. These third-party lab tests cost money, but they are non-negotiable for legal market access. In addition, our own internal Quality Control (QC) team inspects your production run. This adds a small cost but provides immense value. I have heard horror stories of importers who chose a cheaper factory that skipped QC. They saved fifty cents per unit but received a container of faulty products, wiping out their entire investment.

Conclusion

Understanding stationery manufacturing costs is about more than just price; it’s about creating value. By smartly balancing materials, manufacturing complexity, customization level, and logistics, you can develop a product that delights customers and builds your brand. A great partner makes this complex process simple, transparent, and predictable, helping you navigate every step with confidence.